Post-welding protection dragging cover for titanium alloy laser-MIC composite welding and welding method

A welding method and a technology of a protective cover, which are applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor thermal conductivity, inapplicability, and high production cost, and achieve the increase of protection time, prevention of air entrapment, and protection of area Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

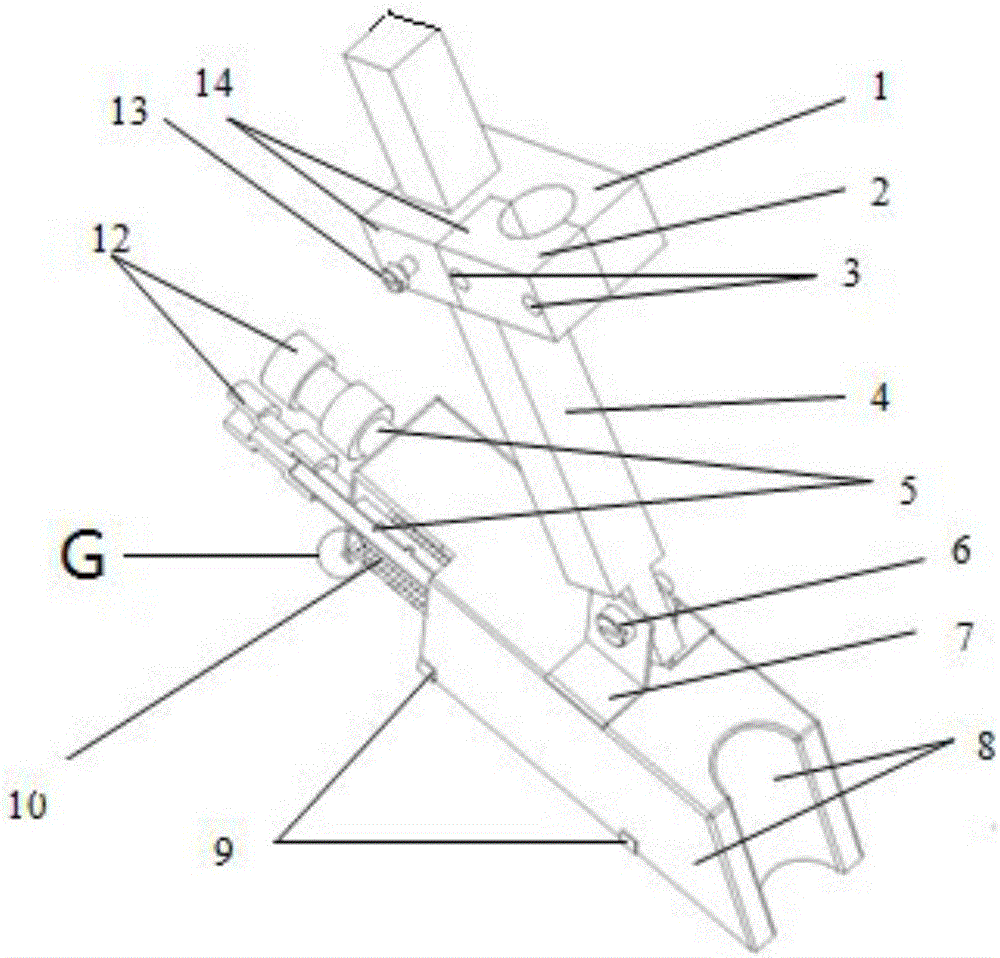

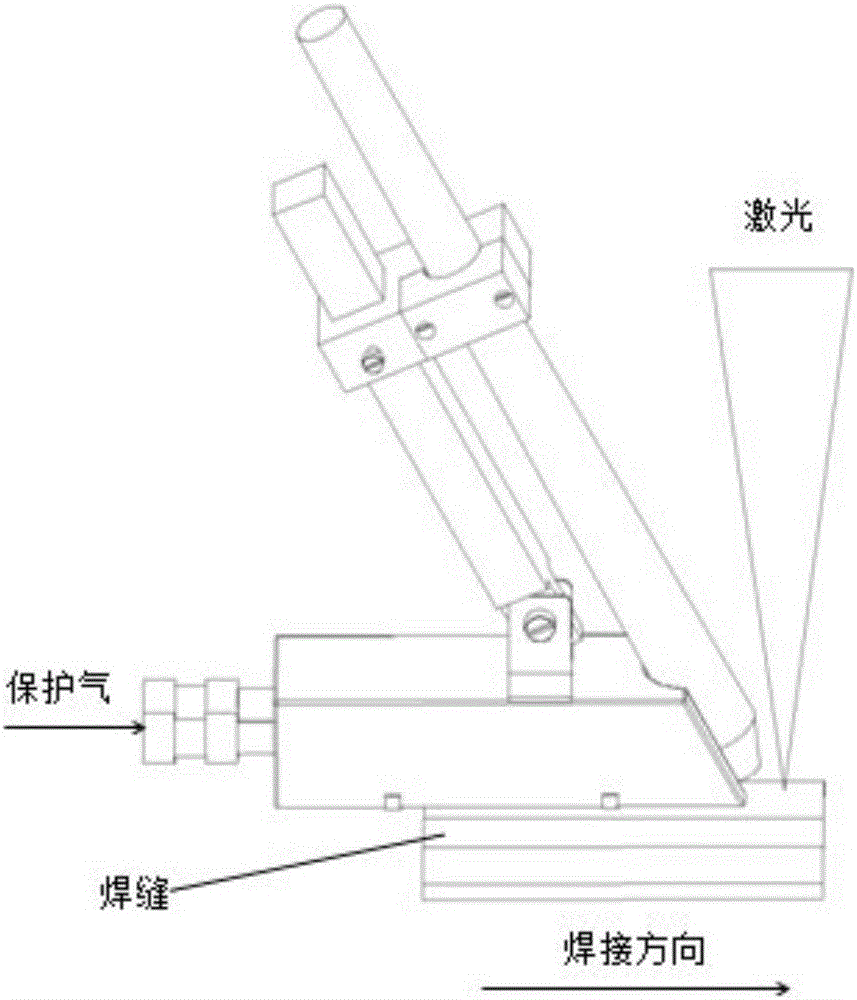

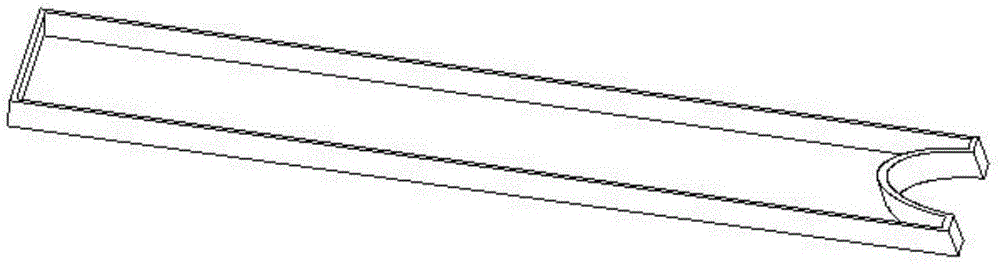

[0029] Such as Figure 1 to Figure 4 As shown, a protective drag cover for titanium alloy laser-MIG composite welding after welding, including a fixed connector 14, a connecting cross bar 4, a shell protective cover 8, an air pipe 5, a pneumatic quick-insert air pipe joint 12, and a copper mesh 10. The fixed connector 14 is fixed on one side of the MIG welding torch, the connecting bar 4 connects the fixed connecting member 14 and the housing protective cover 8, and the connecting bar 4 is provided with a scale, and the housing protective cover 8 Close to the lower end of the MIG welding torch, the ventilation pipe 5 is a stainless steel pipe with a row of regular small round holes on the two pipe walls and closed at one end. The closed surface of the body, the copper mesh 10 is embedded in the housing protective cover through the elastic clip 9 and the arc-shaped rectangular sleeve 11, the pneumatic quick-insert air pipe joint 12 is connected to the air intake end of the air ...

Embodiment 2

[0039] As the preferred technical solution of the present invention, according to the adjustment of welding parameters of laser-MIG hybrid welding of titanium plates, taking TA2 industrial pure titanium with a size of 120mm×60mm×3mm as an example, the parameters are welded according to the following process parameters , the laser output power is 2000W, the welding speed is 1.2m / min, the defocus is -2mm, the welding current is 100A, the distance between the light wires is 3mm, the elongation of the welding wire is 13mm, and the protective gas flow rate of the MIG welding torch is 15L / min, the back shielding gas flow rate is 50L / min, the protective gas flow rate of the shell protective cover after laser-MIG hybrid welding is 50L / min, after the welding is completed, the shell protective cover stays for 30s after laser-MIG welding for continuous protection seam. The welded seam welded with the process parameters of this embodiment has a completely penetrated back side, and the sh...

Embodiment 3

[0041] As the preferred technical solution of the present invention, according to the adjustment of welding parameters of titanium plate laser-MIG hybrid welding, taking TA2 industrial pure titanium with a size of 120mm×60mm×4.2mm as an example, the parameters are set according to the following process parameters For welding, the laser output power is 3750W, the welding speed is 1.2m / min, the defocus is 0mm, the welding current is 100A, the distance between the light wires is 2mm, the elongation of the welding wire is 13mm, and the protective gas flow rate of the MIG welding torch is 15L / min, the back shielding gas flow rate is 50L / min, and the protective gas flow rate of the shell protective cover after laser-MIG hybrid welding is 50L / min. welds. The welding seam welded with the process parameters of this embodiment has a beautiful front shape, a silvery white surface, and no spatter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com