Treatment method of rubber wastewater

A rubber waste water and treatment method technology, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve unsatisfactory problems, save maintenance and operating costs, and save operating costs , the effect of excellent treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

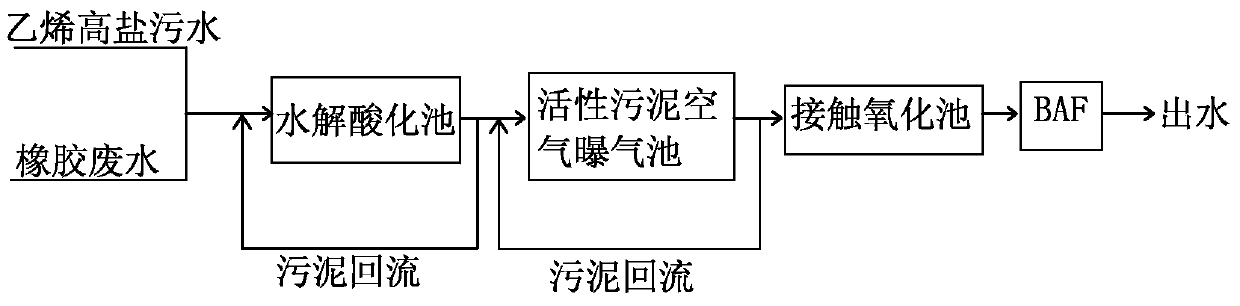

Image

Examples

Embodiment 1

[0036] The mixing volume ratio of rubber wastewater and high-salt wastewater in the influent is 1:16, the COD of rubber wastewater is 210-240mg / L, and the NH 3 -N is 8.0 to 12.0 mg / L.

[0037] Use the following processing methods for processing:

[0038] (1) After mixing the rubber sewage and ethylene high-salt sewage (the ethylene high-salt sewage is the sewage produced in the ethylene production process) in proportion, it is first pumped into the hydrolytic acidification tank. Under the action of bacteria, the organic pollutants in it are degraded into small molecular substances, and the biodegradability of sewage is improved. The hydraulic retention time of the hydrolytic acidification tank is 11.3h, the dissolved oxygen is <0.5mg / L, and the sludge reflux ratio is 100 %, the sludge concentration is 3mg / L; after the effluent is separated from mud and water, the settled sludge flows back to the front end of the hydrolytic acidification tank, and the supernatant flows into th...

Embodiment 2

[0044] The mixing volume ratio of rubber wastewater and high-salt wastewater in the influent is 1:8, the COD of rubber wastewater is 220-250mg / L, and the NH 3 -N is 9.8 to 15.6 mg / L.

[0045] Use the following processing methods for processing:

[0046] (1) After mixing rubber sewage and ethylene high-salt sewage (ethylene high-salt sewage is sewage produced in the process of ethylene production, calcium ions at 3000mg / L and chloride ions at 4000mg / L) in proportion, first pump it into the hydrolysis acidification tank , the hydrolytic acidification tank adopts submerged stirring to realize the mixing of mud and water. Under the action of facultative bacteria, the organic pollutants in it are degraded into small molecular substances, and the biodegradability of sewage is improved. The hydraulic retention time of the hydrolytic acidification tank is 11.3h, and the dissolved Oxygen is <0.5mg / L, sludge reflux ratio is 80%, and sludge concentration is 4mg / L; after the effluent is ...

Embodiment 3

[0052] The mixing volume ratio of rubber wastewater and high-salt wastewater in the influent is 1:4, the COD of rubber wastewater is 220-250mg / L, and the NH 3 -N is 9.8 to 15.6 mg / L.

[0053] Use the following processing methods for processing:

[0054] (1) After mixing rubber sewage and ethylene high-salt sewage (ethylene high-salt sewage is sewage produced in the process of ethylene production, calcium ions are at 5300mg / L, and chloride ions are at 8000mg / L), they are first pumped into the hydrolysis acidification tank , the hydrolytic acidification tank adopts submerged stirring to realize the mixing of mud and water. Under the action of facultative bacteria, the organic pollutants in it are degraded into small molecular substances, and the biodegradability of sewage is improved. The hydraulic retention time of the hydrolytic acidification tank is 11.3h, and the dissolved Oxygen is <0.5mg / L, sludge reflux ratio is 50%, and sludge concentration is 4mg / L; after the effluent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com