A method of loading ultrafine metal nanoparticles in the inner channel of microporous material

A technology of metal nanoparticles and microporous materials, which is applied in the field of nanomaterials and nanometers, can solve the problems of large Pt nanoparticle size, large pore size of mesoporous materials, and affecting performance, so as to avoid deposition agglomeration, high dispersion, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

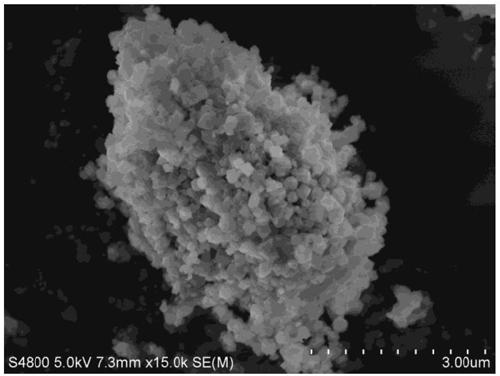

[0033] This example provides a preparation of highly monodisperse Pt metal nanoparticles@microporous composite material (Pt@MIL-101-Cr), the specific steps are as follows:

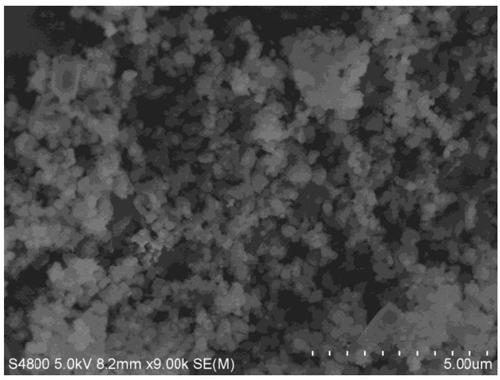

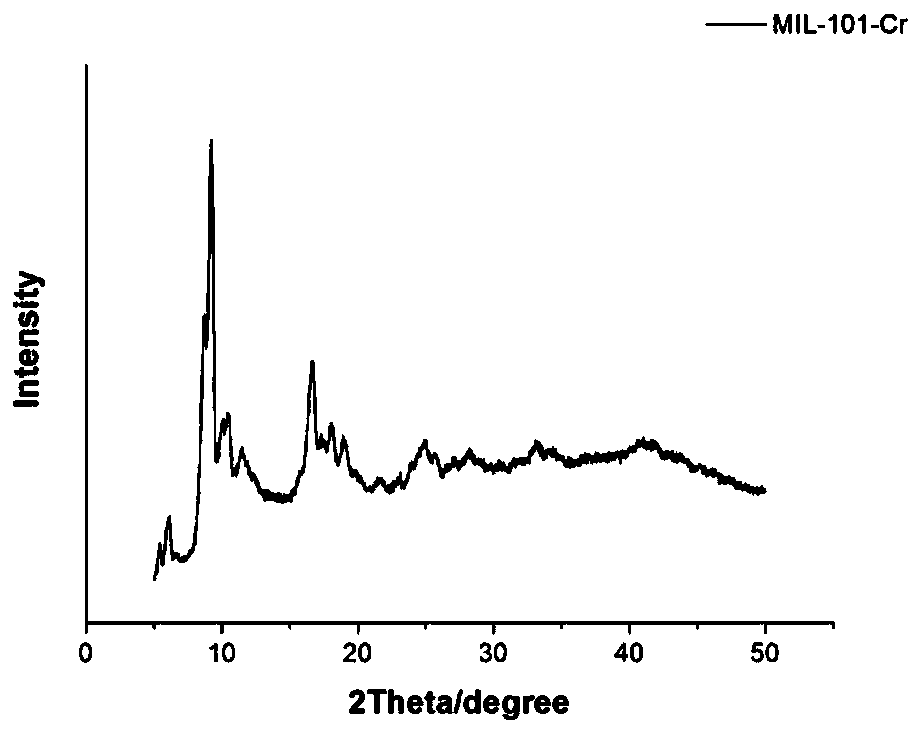

[0034] (1) Synthesis of microporous material MIL-101-Cr with hydrophilic channels:

[0035] 0.66 g of terephthalic acid (4.0 mmol) was added to 20 ml of a 0.05 mol / L aqueous solution of tetramethylammonium hydroxide, and stirred at room temperature for 10 minutes. Then add 1.6gCr(NO 3 ) 3 .9H 2 O (4.0 mmol) was added into the mixed solution, and stirring was continued for another 20 minutes. The final obtained suspension was transferred to a polytetrafluoroethylene-lined kettle and heated at 180°C for 24 hours (the time required for heating was 10 hours, and the time required for cooling was 18 hours, and the heating and cooling time did not include within 24 hours);

[0036] (2) Place the MIL-101-Cr sample in a vacuum oven at 150°C for 12 hours;

[0037] (3) 100 mg of MIL-101-Cr green powder sample ...

Embodiment 2

[0046] This example provides a preparation of highly monodisperse Pt metal nanoparticles@microporous composite material (Pt@MOF-808), the specific steps are as follows:

[0047] (1) Synthesis of MOF-808, a microporous material with hydrophilic channels:

[0048] 0.11 g trimesic acid (0.5 mmol) and 0.32 g zirconium oxychloride octahydrate ZrOCl 2 ·8H 2 O (0.5mmol) was added to a mixed solution of 20mL DMF (N,N-dimethylformamide) and 20mL formic acid, and heated and stirred at 100°C for 7 days. The resulting solid powder was washed three times with DMF, each time using 10 mL of DMF.

[0049] (2) Place the MOF-808 sample in a vacuum oven at 120°C for 12 hours;

[0050] (3) Take 100 mg of MOF-808 powder sample and dissolve it in 25 ml of anhydrous n-hexane, which is used as a hydrophobic solvent. The obtained suspension was sonicated for 15 minutes with an ultrasonic oscillator to make the suspension into a uniform solution, and then stirred at room temperature for 2 hours. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com