Preparation of carbon quantum dots based on coal tar asphalt and detection method for HCHO

A technology of coal tar pitch and carbon quantum dots, which is applied in the application field of fluorescent carbon nanomaterials, can solve the problems of high detection limit and achieve the effect of simple method, cheap raw materials and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

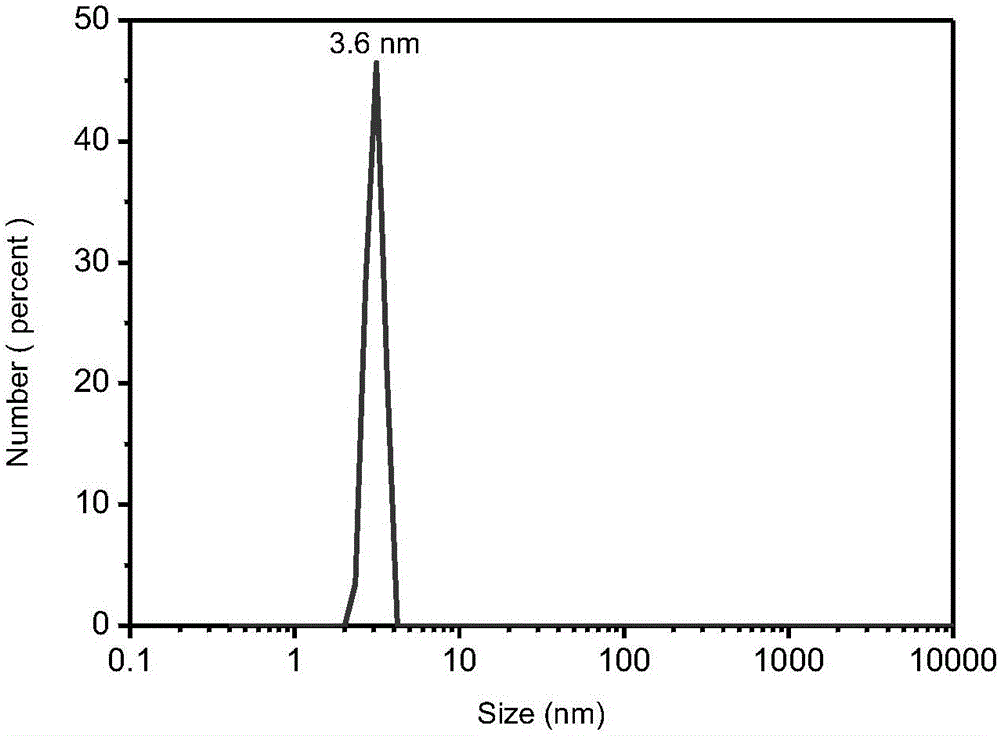

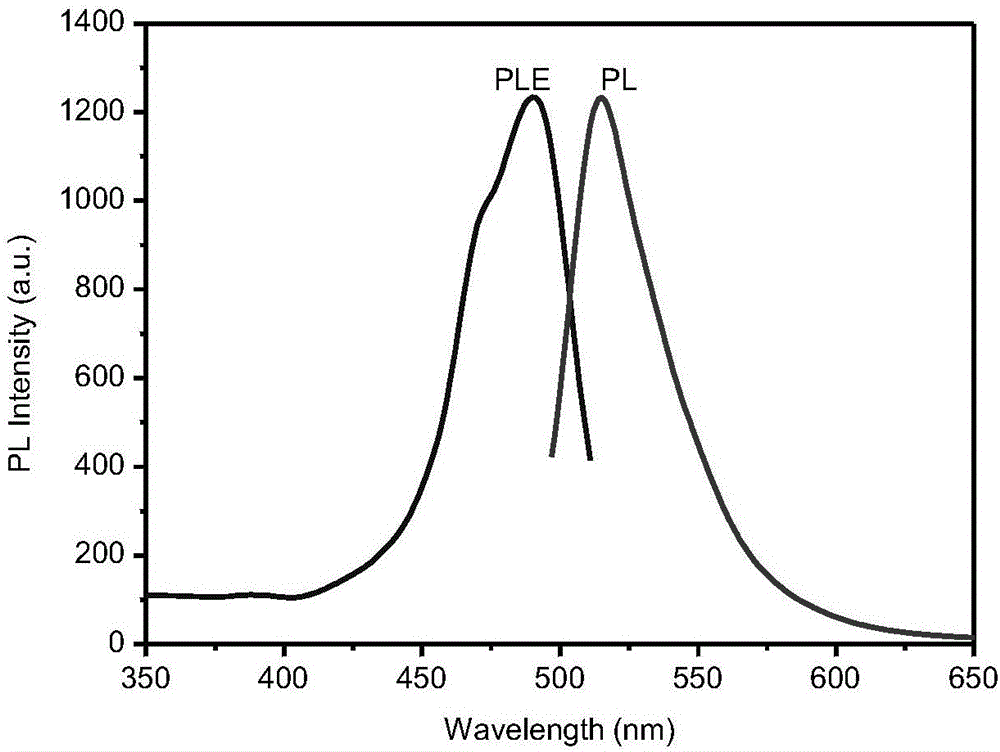

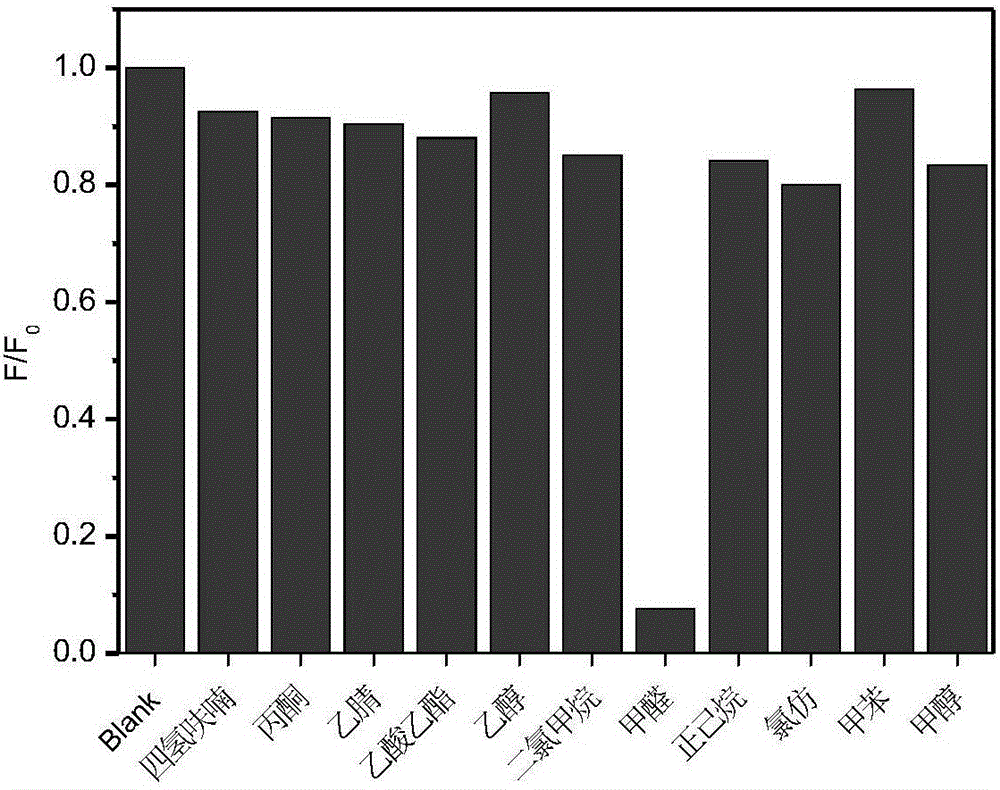

[0026] Take 1g of coal tar pitch and grind it to about 40 μm in a coffee machine, add a small amount of deionized water and pass it through a 500rpm ball mill for ball milling for 4 hours, transfer it to a three-necked flask, add 50mL of 10% hydrogen peroxide, and reflux and condense at 60°C for 6 hours After the reaction, the product was centrifuged in a high-speed centrifuge at 18,000rpm for 20 minutes, and the supernatant was taken, and was rotary evaporated to a solid at 70°C, and dried in a vacuum oven for 12 hours to obtain light yellow carbon quantum dot powder.

Embodiment 2

[0028] Take 1g of coal tar pitch and grind it to about 40μm in a coffee machine, add a small amount of deionized water and pass it through a 500rpm ball mill for ball milling for 4h, transfer it to a three-necked flask, add 50mL of 20% hydrogen peroxide, and reflux and condense at 60°C for 6h After the reaction, the product was centrifuged in a high-speed centrifuge at 15,000rpm for 20min, and the supernatant was taken, and was rotary evaporated to a solid at 70°C, and dried in a vacuum oven for 12h to obtain light yellow carbon quantum dot powder.

Embodiment 3

[0030] Take 1g of coal tar pitch and grind it to about 40μm in a coffee machine, add a small amount of deionized water and pass it through a 500rpm ball mill for ball milling for 4h, transfer it to a three-necked flask, add 50mL of 20% hydrogen peroxide, and reflux and condense at 60°C for 6h After the reaction, the product was centrifuged in a high-speed centrifuge at 18,000rpm for 30 minutes, and the supernatant was taken, and was rotary evaporated to a solid at 70°C, and dried in a vacuum oven for 12 hours to obtain light yellow carbon quantum dot powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com