Electroplate liquid for cyanide-free silver plating and electroplating method of electroplate liquid

A technology of cyanide-free silver plating and electroplating solution, applied in the field of cyanide-free electroplating, can solve problems such as environmental threats, and achieve the effects of improving sensitivity, small coating stress and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

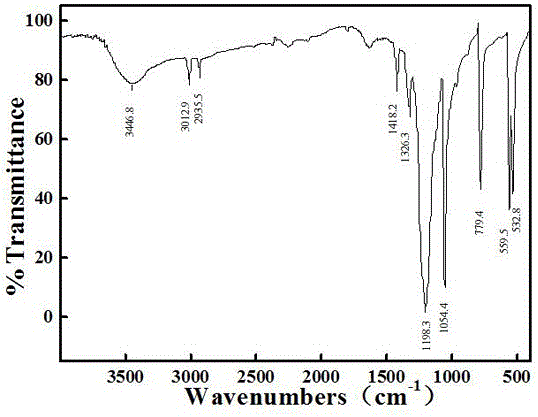

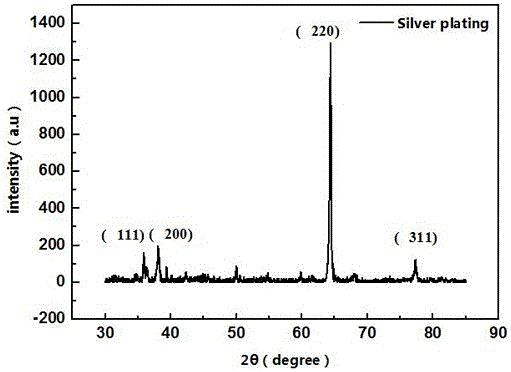

Method used

Image

Examples

Embodiment 1

[0024] A kind of electroplating solution of cyanide-free silver plating, comprising that mass concentration is 25g / L silver methanesulfonate, 15g / L silver carbene sulfonate, 63g / L citric acid, 11.5g / L sodium dihydrogen phosphate, 400ppm aminotrimethylene Phosphonic acid, 0.5mL / L phytic acid. The pH value of the electroplating solution is controlled at 7.

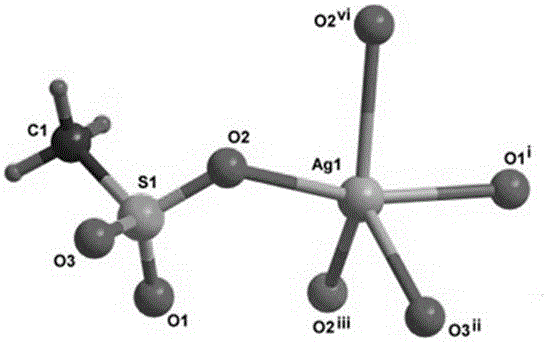

[0025] The chemical structural formula of described silver carbene sulfonate is .

[0026] A kind of electroplating method of the electroplating solution of cyanide-free silver plating, comprises the following steps:

[0027] S1. Prepare the above-mentioned electroplating solution, and adjust the temperature of the electroplating solution to be 55° C.;

[0028] S2. Use the silver plate as the anode and the piece to be plated as the cathode, apply a single pulse power supply between the anode and the cathode, the pulse width of the single pulse power supply is 120ms, the duty cycle is 55%, and the average pulse current de...

Embodiment 2

[0031] A kind of electroplating solution of cyanide-free silver plating, comprise that mass concentration is 55g / L silver methanesulfonate, 20g / L silver carbene sulfonate, 63g / L citric acid, 21.5g / L sodium dihydrogen phosphate, 400ppm aminotrimethylene Phosphonic acid, 10.5mL / L phytic acid. The pH value of the electroplating solution is controlled at 7.

[0032] The chemical structural formula of described silver carbene sulfonate is .

[0033] A kind of electroplating method of the electroplating solution of cyanide-free silver plating, comprises the following steps:

[0034] S1. Prepare the above-mentioned electroplating solution, and adjust the temperature of the electroplating solution to be 55° C.;

[0035] S2. Use the silver plate as the anode and the piece to be plated as the cathode, apply a single pulse power supply between the anode and the cathode, the pulse width of the single pulse power supply is 120ms, the duty cycle is 55%, and the average pulse current den...

Embodiment 3

[0038] A kind of electroplating solution of cyanide-free silver plating, comprises that mass concentration is 45g / L silver methanesulfonate, 25g / L silver carbene sulfonate, 13g / L citric acid, 11.5g / L sodium dihydrogen phosphate, 800ppm aminotrimethylene Phosphonic acid, 0.5mL / L phytic acid. The pH value of the electroplating solution is controlled at 7.

[0039] The chemical structural formula of described silver carbene sulfonate is .

[0040] A kind of electroplating method of the electroplating solution of cyanide-free silver plating, comprises the following steps:

[0041] S1. Prepare the above-mentioned electroplating solution, and adjust the temperature of the electroplating solution to be 55° C.;

[0042] S2. Use the silver plate as the anode and the piece to be plated as the cathode, apply a single pulse power supply between the anode and the cathode, the pulse width of the single pulse power supply is 120ms, the duty cycle is 55%, and the average pulse current densi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap