High performance capacitor impregnating agent

A capacitor and impregnating agent technology, which is applied in the direction of capacitors, fixed capacitors, fixed capacitor dielectrics, etc., can solve the problems of general fluidity and heat resistance of the impregnating agent, affect the life of the capacitor, and the performance of the impregnating agent is not high, so as to improve the dielectric strength and volume resistivity, significant economic benefits, and the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

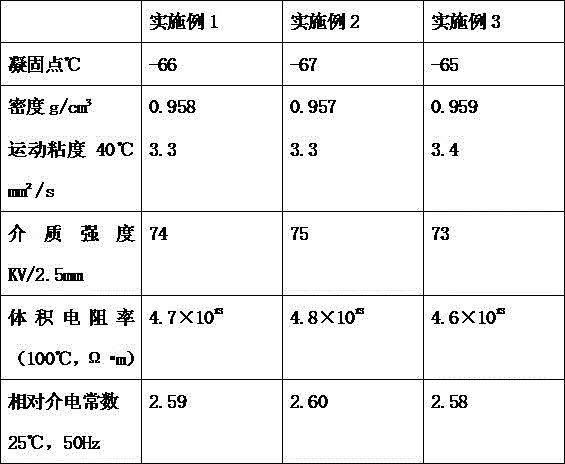

Embodiment 1

[0017] A high-performance capacitor impregnant, which is made from the following ingredients in parts by weight: castor oil 80, olive oil 30, sodium benzene sulfonate 1, auxiliary material 3, diffusing agent MF0.8, pumpkin seed oil 3, suberic acid 8 , Cottonseed oil 3; The auxiliary material is made of the following ingredients in parts by weight: bentonite 6, bauxite 10, diatomite 2.

Embodiment 2

[0019] A high-performance capacitor impregnant, which is made from the following ingredients in parts by weight: castor oil 100, olive oil 40, sodium benzenesulfonate 4, auxiliary material 6, diffusing agent MF1, pumpkin seed oil 6, suberic acid 13, cotton seed Oil 6; The auxiliary materials are made of the following ingredients in parts by weight: bentonite 10, bauxite 15, and diatomite 6.

Embodiment 3

[0021] A high-performance capacitor impregnating agent, which is made from the following ingredients in parts by weight: castor oil 90, olive oil 35, sodium benzenesulfonate 2, auxiliary material 4, diffusing agent MF0.9, pumpkin seed oil 4, suberic acid 10 , Cottonseed oil 5; The auxiliary material is made of the following ingredients in parts by weight: bentonite 8, bauxite 12, and diatomite 3.

[0022] The preparation method of the auxiliary material in the above embodiment is:

[0023] ① The bentonite is calcined at 325°C for 20 minutes, and when it is cooled to 40°C, it is added to a 5% sodium hypochlorite solution and soaked for 20 minutes, then filtered, washed, and dried;

[0024] ② The bauxite is calcined at 275°C for 15 minutes, and when it is cooled to 45°C, it is added to a sodium hypochlorite solution with a mass fraction of 8% and soaked for 15 minutes, then filtered, washed, and dried;

[0025] ③ Calcined diatomaceous earth at 225°C for 10 minutes, and when cooled to 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com