Anti-electromagnetic interference resistive memory and preparation method thereof

An anti-electromagnetic interference and resistive memory technology, applied in the field of microelectronics, can solve the problems of polluting the surrounding environment, accelerating waste of electronic devices, and detrimental to human health, and achieves the effects of simple process, efficient electromagnetic shielding, and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

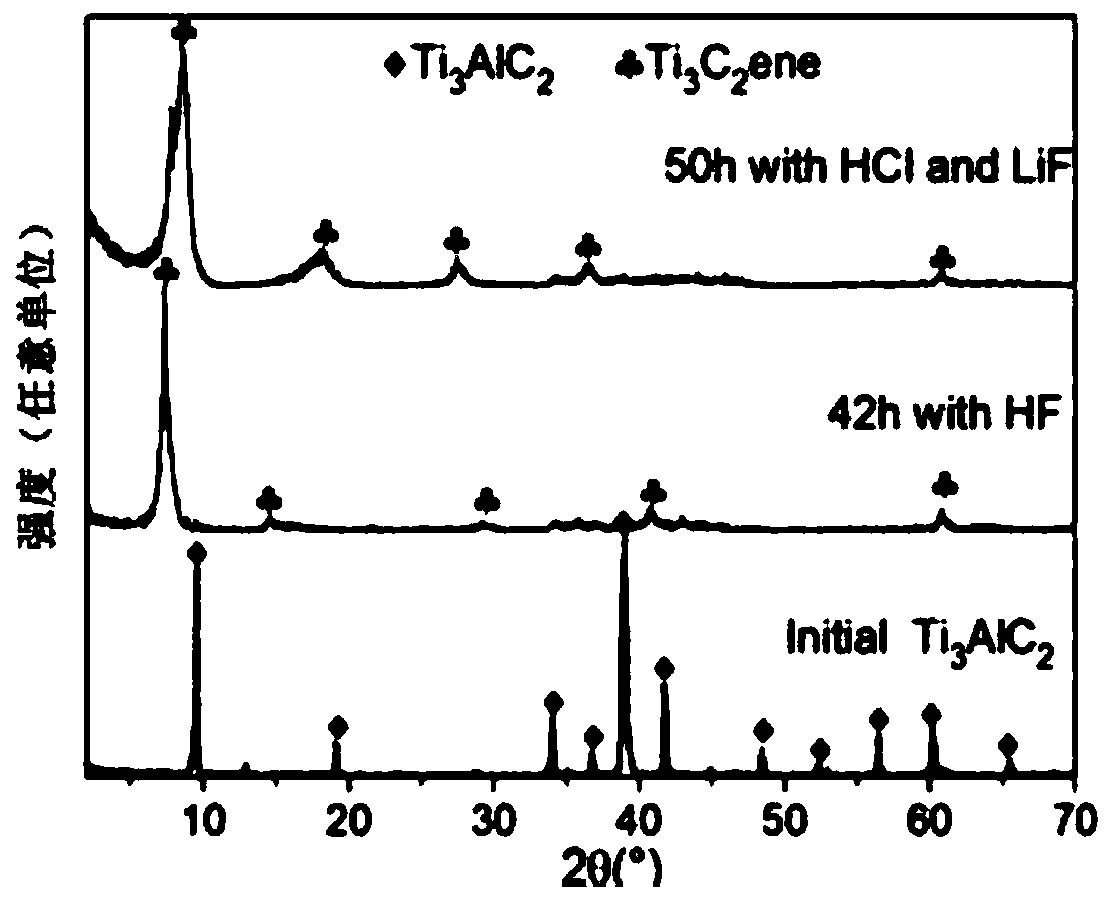

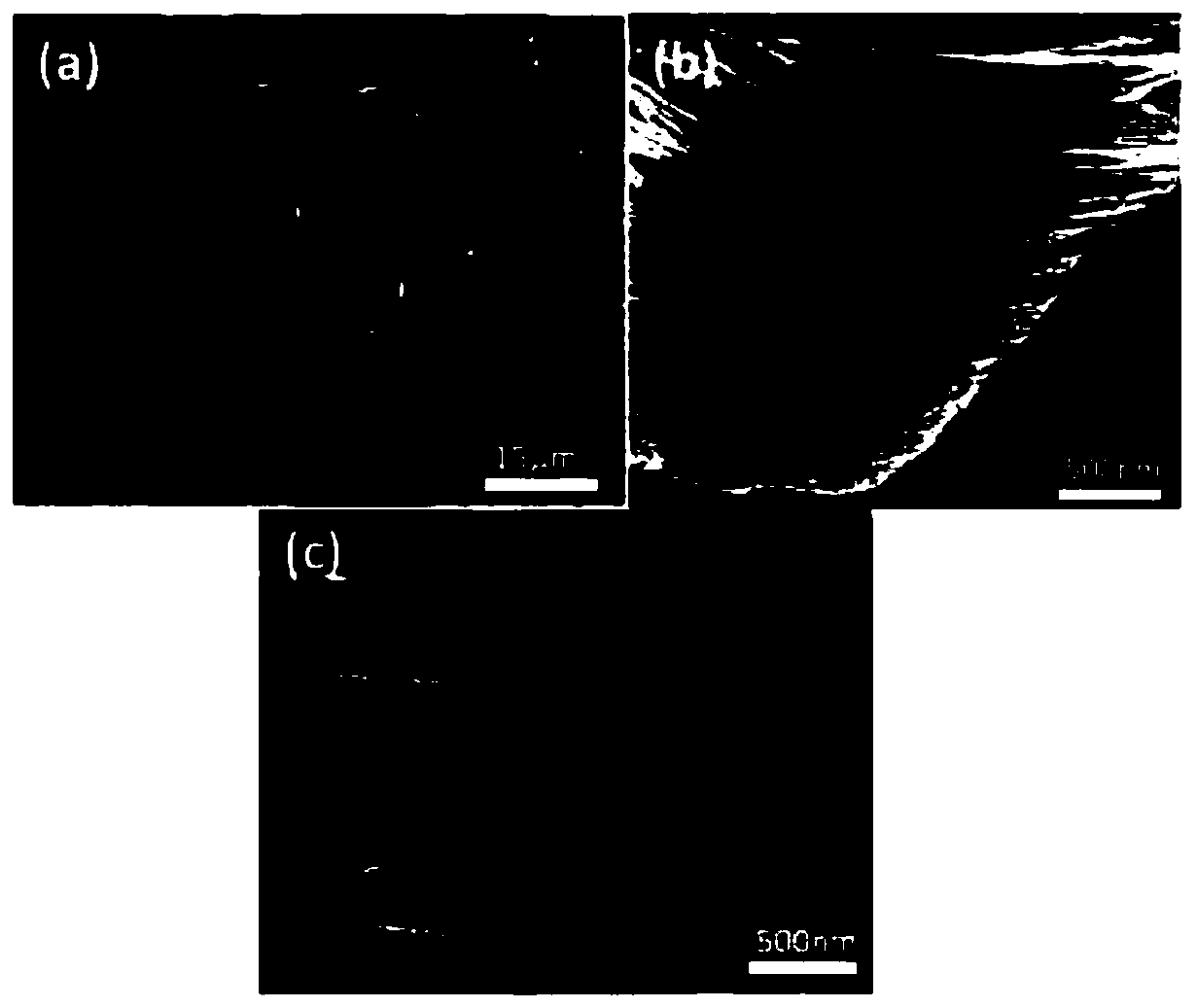

[0025] Electromagnetic shielding electrode material Ti 3 C 2 The preparation method of ene film specifically comprises the following steps:

[0026] Step 1: 3 g of Ti with a particle size of 45 μm 3 AlC 2 The powder is placed in a tetrafluoroethylene beaker filled with 35ml mass fraction of 40% HF;

[0027] Step 2: heating at 40°C for 42 hours, then naturally cooling to room temperature;

[0028] Step 3: Prepare the obtained black liquid, and wash it several times with deionized water repeatedly to remove the remaining reaction reagents.

[0029] Step 4: Use a dropper to drop the black liquid onto the substrate and dry it to obtain Ti 3 C 2 ene film material.

Embodiment 2

[0031] Electromagnetic shielding electrode material Ti 3 C 2 The preparation method of ene film specifically comprises the following steps:

[0032] Step 1: Take 6mol / L HCL solution;

[0033] Step 2: Add 1.98g of LiF to it;

[0034] Step 3: Mix 3g of Ti in 10 minutes 3 AlC 2 added to the solution;

[0035] Step 4: Heating at 40°C for 42 hours, then cooling to room temperature naturally.

[0036] Step 5: Prepare the obtained black liquid, and wash it several times with deionized water repeatedly to remove the remaining reaction reagents.

[0037] Step 6: Use a dropper to drop the black liquid onto the substrate and dry it to obtain Ti 3 C 2 ene film material.

Embodiment 3

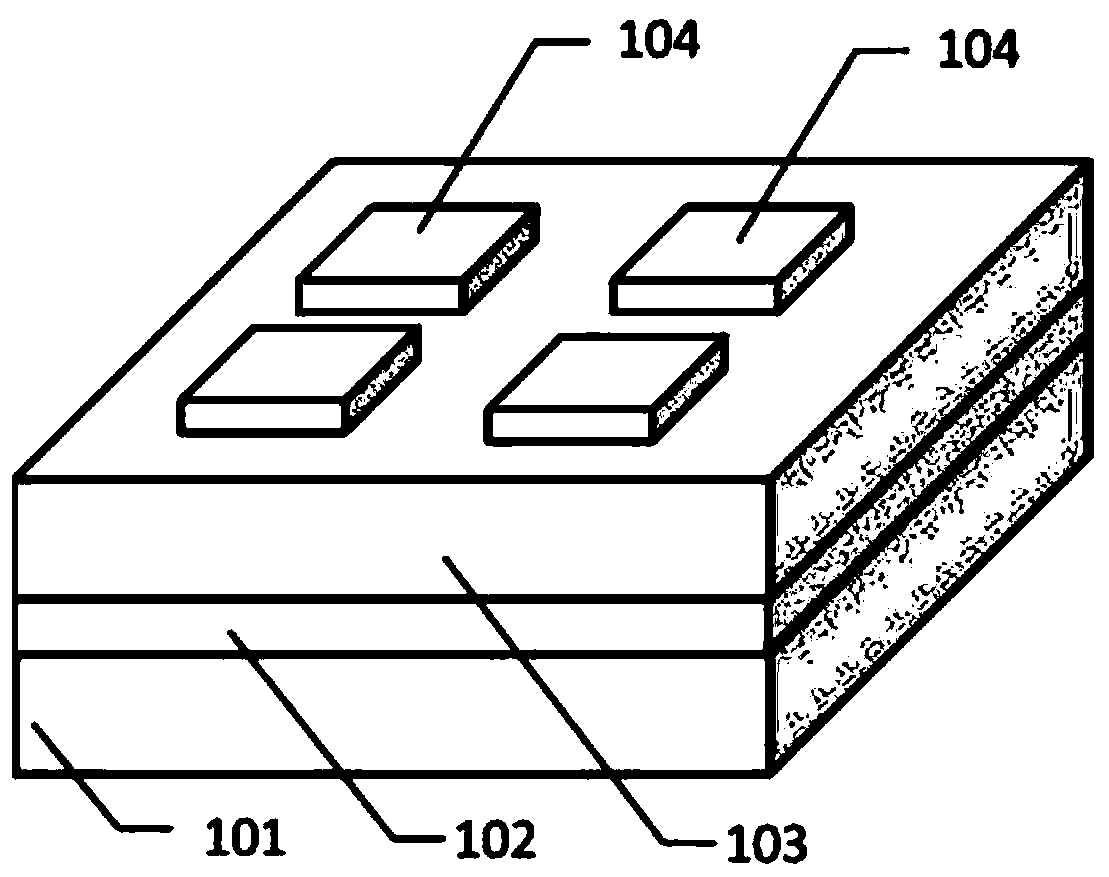

[0039] A method for preparing an anti-electromagnetic interference resistive variable memory, specifically comprising the following steps:

[0040] (1) Transfer Ti on the base material 3 C 2 ene film material, Ti 3 C 2 The preparation method of the ene film material uses one of the methods in Example 1 or Example 2.

[0041] (2) Using magnetron sputtering technology on Ti 3 C 2 Deposit storage function layer thin film material HfO on the ene thin film material 2 , the specific process is as follows: the background vacuum is 5×10 -5 Pa, working pressure 2Pa, Ar gas flow 20sccm, RF power 60W, deposition time 40min, HfO 2 The film thickness is 30nm.

[0042] (3) in HfO 2 Ti transfer on thin film surface 3 C 2 ene film material, Ti 3 C 2 The preparation method of the ene film material uses one of the methods in Example 1 or Example 2.

[0043] (4) On the top layer Ti 3 C 2 A layer of photoresist is suspended on the surface of the ene film material, and exposed to l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com