Crispy sun-dried cucumber skin production method

A production method and technology of cucumber rind, applied in the functions of food ingredients, food ingredients containing natural extracts, food science, etc., can solve problems such as low safety, poor taste, and calcium chloride can only keep crisp, and achieve Good taste and high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

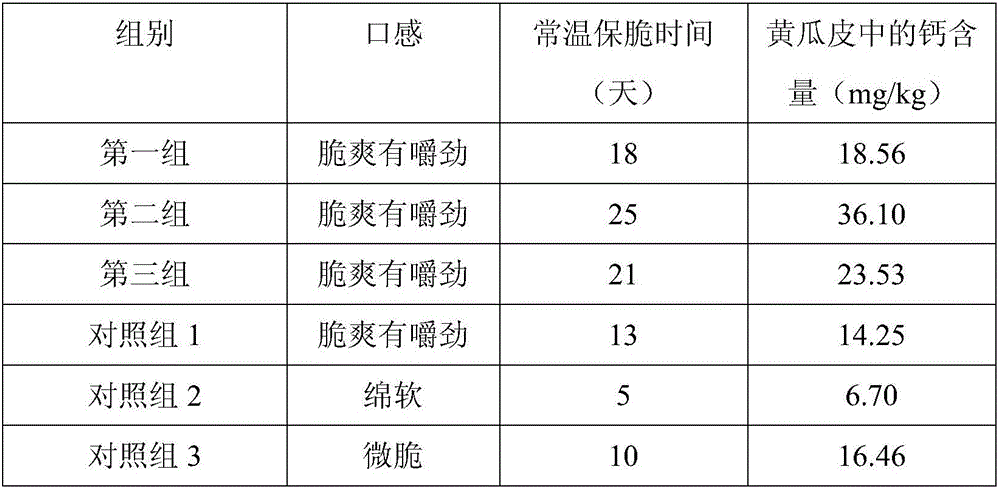

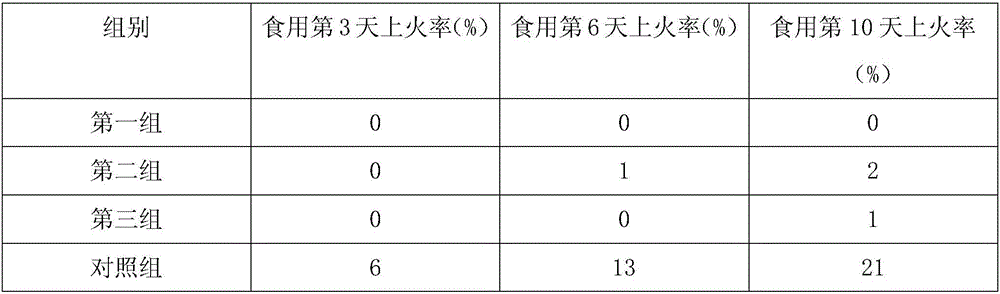

Examples

Embodiment 1

[0036] In this embodiment, a method for making crispy sun-dried cucumber peel includes the following steps:

[0037] (1) Selection of raw materials: choose white cucumbers whose skin color has not turned yellow and the seeds have not hardened, washed and cut into cucumbers with a length of 3-6cm, a width of 1-1.5cm and a thickness of 2-5mm Article spare;

[0038] (2) Crisp preservation treatment: Place the above cucumber strips in steam at 90°C for 90 seconds, take out and cool, add the cooled cucumber strips to the mixture of calcium malate and L-malic acid and soak for 1 hour. Take it out to obtain a processed cucumber strip, the weight ratio of calcium malate, L-malic acid, and water is 1:5:60;

[0039] (3) Drying: Put the processed cucumber strips in the sun to dry until the weight is 25% of the weight of the processed cucumber strips;

[0040] (4) Marinating with seasonings: adding the dried cucumber strips to 8% Chinese medicinal solution, 3% salt, 0.5% white sugar, 6% cooking ...

Embodiment 2

[0043] In this embodiment, a method for making crispy sun-dried cucumber peel includes the following steps:

[0044] (1) Selection of raw materials: choose white cucumbers whose skin color has not turned yellow and the seeds have not hardened, washed and cut into cucumbers with a length of 3-6cm, a width of 1-1.5cm and a thickness of 2-5mm Article spare;

[0045] (2) Crisp preservation treatment: Place the above cucumber strips in steam at 100°C for 60 seconds, take out and cool, add the cooled cucumber strips to the mixture of calcium malate and L-malic acid and soak for 2 hours. Take it out to obtain a processed cucumber strip, the weight ratio of calcium malate, L-malic acid and water is 2:8:80;

[0046] (3) Drying: Put the treated cucumber strips in the sun to dry until the weight is 35% of the weight of the treated cucumber strips;

[0047] (4) Marinating with seasoning: adding the dried cucumber strips to 13% Chinese medicinal solution, 5% salt, 1.5% white sugar, 9% cooking win...

Embodiment 3

[0050] In this embodiment, a method for making crispy sun-dried cucumber peel includes the following steps:

[0051] (1) Selection of raw materials: choose white cucumbers whose skin color has not turned yellow and the seeds have not hardened, washed and cut into cucumbers with a length of 3-6cm, a width of 1-1.5cm and a thickness of 2-5mm Article spare;

[0052] (2) Crisp preservation treatment: Place the above cucumber strips in steam at 95°C for 75 seconds, take it out and cool, add the cooled cucumber strips to the mixture of calcium malate and L-malic acid and soak for 1.5 hours. Take it out to obtain processed cucumber strips, the weight ratio of calcium malate, L-malic acid, and water is 1.5:7:70;

[0053] (3) Drying: Put the processed cucumber strips in the sun to dry until the weight is 30% of the weight of the processed cucumber strips;

[0054] (4) Marinating with seasoning: adding the dried cucumber strips to the 10% Chinese medicinal solution, 4% salt, 1% white sugar, 8%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com