Catalyst used for synthesizing vinyl chloride through acetylene hydrochlorination

A technology for the synthesis of vinyl chloride and catalysts by hydrochlorination of acetylene, applied in the field of catalysis, can solve the problems of low selectivity, many side reactions, and low catalyst activity, and achieve the effects of high activity, high selectivity, and high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

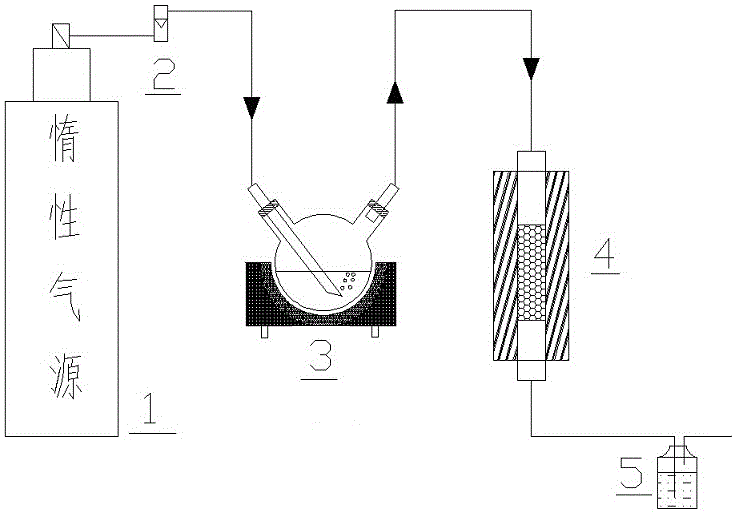

Image

Examples

Embodiment 1

[0019] Weigh 5ml of citric acid, add 30ml of deionized water, stir to dissolve, and control the temperature of the dipping solution to 40°C by heating with an electric heating mantle. Add 15g of dry activated carbon, immerse and stir at 60°C for 12h, dry at 105°C for 8h, and carbonize at 450°C in a tube furnace for 2h at high temperature (modification) to obtain the treated carrier, and then load the active component of bismuth chloride. The initial conversion rate can reach 100%.

Embodiment 2

[0021] Connect the inert gas source nitrogen, control the gas flow rate to 20min / h, measure 20ml of lactic acid, and control the temperature of the impregnation solution to 40°C by heating with the electric heating mantle (to ensure that the liquid level can boil in a large area under the entrainment of the gas, and the steam is carried into the reactor) , Weigh 8g of activated carbon and add it to the reactor. The temperature of the reactor is controlled at 300°C (that is, modification), and the treatment time is maintained for 3 hours to obtain the treated carrier activated carbon, which is then loaded with the active component of copper chloride. The initial conversion rate can reach 100%.

Embodiment 3

[0023] Connect the inert gas source nitrogen, control the gas flow rate at 15ml / min, measure 15ml of tartaric acid, stir to dissolve, adjust the pH value to 1.5 with hydrochloric acid, and control the temperature of the impregnating solution to 50°C by heating with an electric heating mantle. Add 15g of dry activated carbon, impregnate at room temperature for 7h, oven dry at 110°C for 6.5h, and roast in a nitrogen atmosphere in a tube furnace for 3h (modification) to obtain an acetylene hydrochlorination catalyst with an acetylene conversion rate of 67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com