Catalyst for production of ethylene method vinyl acetate

A method of vinyl acetate and catalyst technology, which is applied in the direction of physical/chemical process catalysts, carboxylate preparation, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems of low activity and selectivity of vinyl acetate catalysts, Achieve the effect of improving activity and stability, improving yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

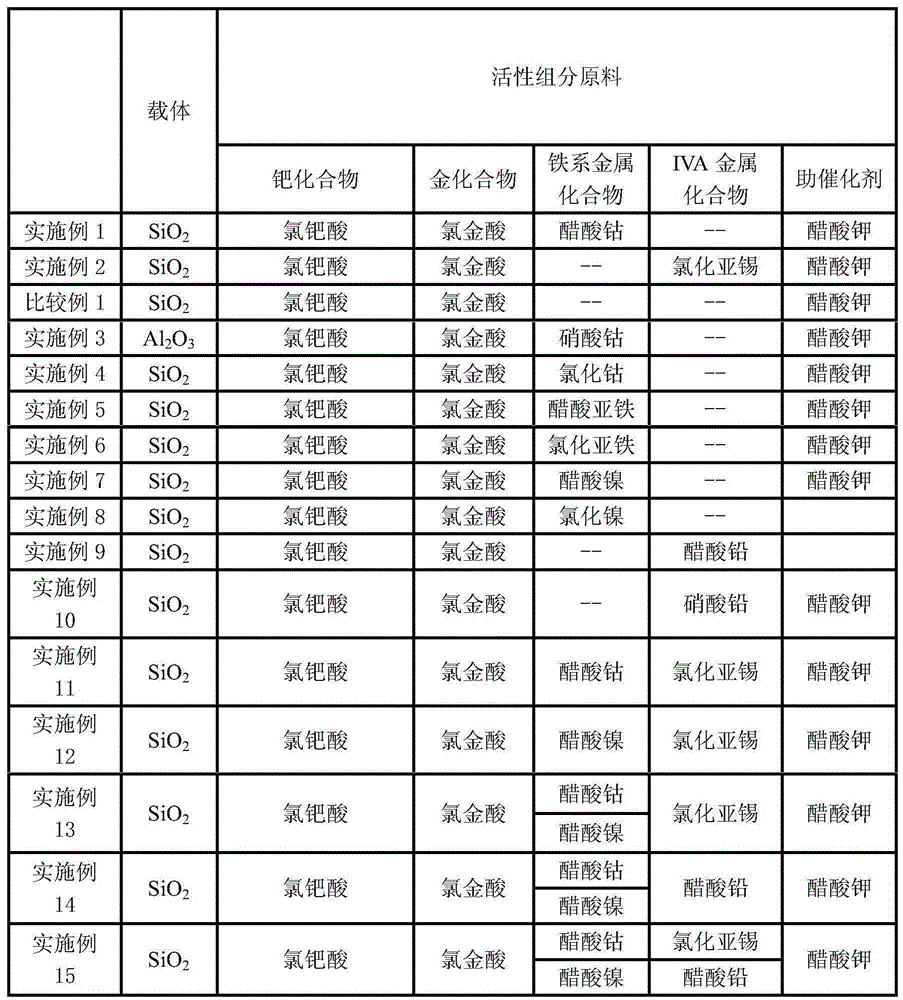

Embodiment 1

[0031] Catalyst preparation:

[0032] (1) Using sodium bicarbonate pH regulator and water as a solvent to prepare a pH of 1.09, containing 3.85gPd and 1.87gAu of chloropalladic acid and chloroauric acid aqueous solution to obtain 500ml of impregnation solution, which is impregnated on the carrier in a rotating pot 1.0L of spherical SiO with a diameter of 5.6mm 2 Catalyst precursor I is obtained on the carrier;

[0033] (2) After drying at 80°C, 98ml contains 20.5g Na 2 SiO 3 9H 2 The solution of O is fully mixed, aged for 24h to obtain catalyst precursor II;

[0034] (3) With a solubility of 12% (in N 2 h 4 ·H 2 (2 in weight ratio) is reduced by 500ml hydrazine hydrate, washed with water to no chloride ion, and dried at 90° C. to obtain catalyst precursor III;

[0035] (4) Cobalt acetate (Co(OA) containing 1.27g CoC ) 2 4H 2 O) 150ml of the aqueous solution is impregnated on the precursor III, vacuum-dried at 110°C, and calcined at 400°C to obtain the catalyst precur...

Embodiment 2

[0042] Catalyst preparation:

[0043] (1) Using sodium bicarbonate pH regulator and water as a solvent to prepare a pH of 1.09, containing 3.85gPd and 1.87gAu of chloropalladic acid and chloroauric acid aqueous solution to obtain 500ml of impregnation solution, which is impregnated on the carrier in a rotating pot 1.0L of spherical SiO with a diameter of 5.6mm 2 Catalyst precursor I is obtained on the carrier;

[0044] (2) After drying at 80°C, 98ml contains 20.5g Na 2 SiO 3 9H 2 The solution of O is fully mixed, aged for 24h to obtain catalyst precursor II;

[0045] (3) With a solubility of 12% (in N 2 h 4 ·H 2 (2 in weight ratio) is reduced by 500ml hydrazine hydrate, washed with water to no chloride ion, and dried at 90° C. to obtain catalyst precursor III;

[0046] (4) The stannous chloride (SnCl) containing 1.27gSn 2 2H 2 O) 150ml of the aqueous solution is impregnated on the precursor III, vacuum-dried at 110°C, and calcined at 400°C to obtain the catalyst prec...

Embodiment 3

[0065] Catalyst preparation:

[0066] (1) Using sodium bicarbonate pH regulator and water as a solvent to prepare a pH of 1.09, containing 3.85gPd and 1.87gAu of chloropalladic acid and chloroauric acid aqueous solution to obtain 500ml of impregnation solution, which is impregnated on the carrier in a rotating pot 1.0L spherical Al with a diameter of 5.6mm 2 o 3 Catalyst precursor I is obtained on the carrier;

[0067] (2) After drying at 80°C, 98ml contains 20.5g Na 2 SiO 3 9H 2 The solution of O is fully mixed, aged for 24h to obtain catalyst precursor II;

[0068] (3) With a solubility of 12% (in N 2 h 4 ·H 2 (2 in weight ratio) is reduced by 500ml hydrazine hydrate, washed with water to no chloride ion, and dried at 90° C. to obtain catalyst precursor III;

[0069] (4) Cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) 150ml of the aqueous solution is impregnated on the precursor III, vacuum-dried at 110°C, and calcined at 400°C to obtain the catalyst precursor IV;

[0070]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com