The preparation method of y-beta composite molecular sieve

A composite molecular sieve block technology, which is applied in the field of preparation of Y-Beta composite molecular sieve, can solve the problem of low cracking activity and achieve the effect of large specific surface area and good cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

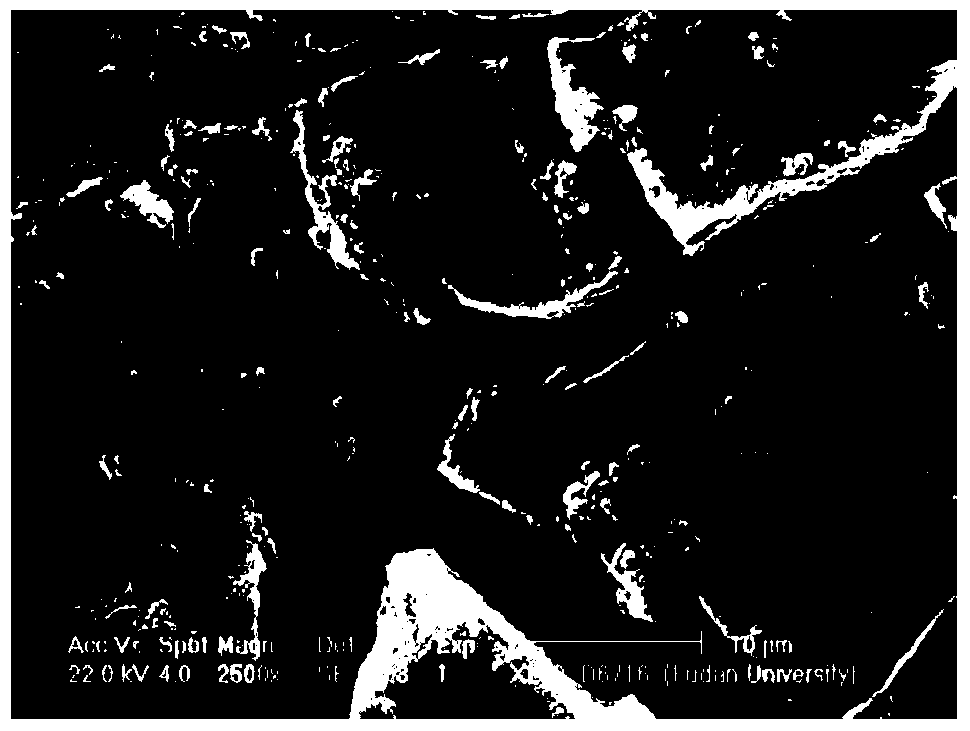

Image

Examples

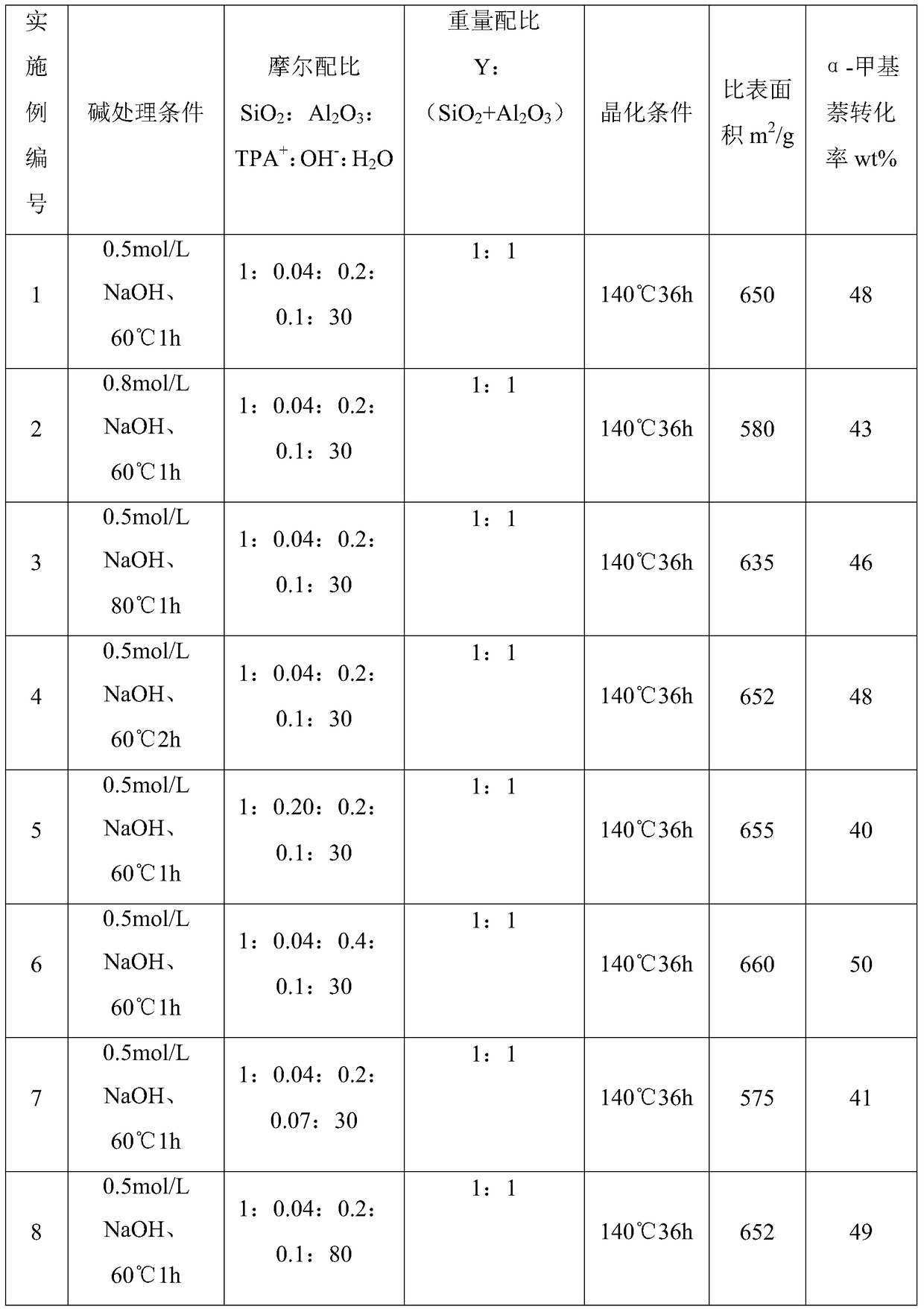

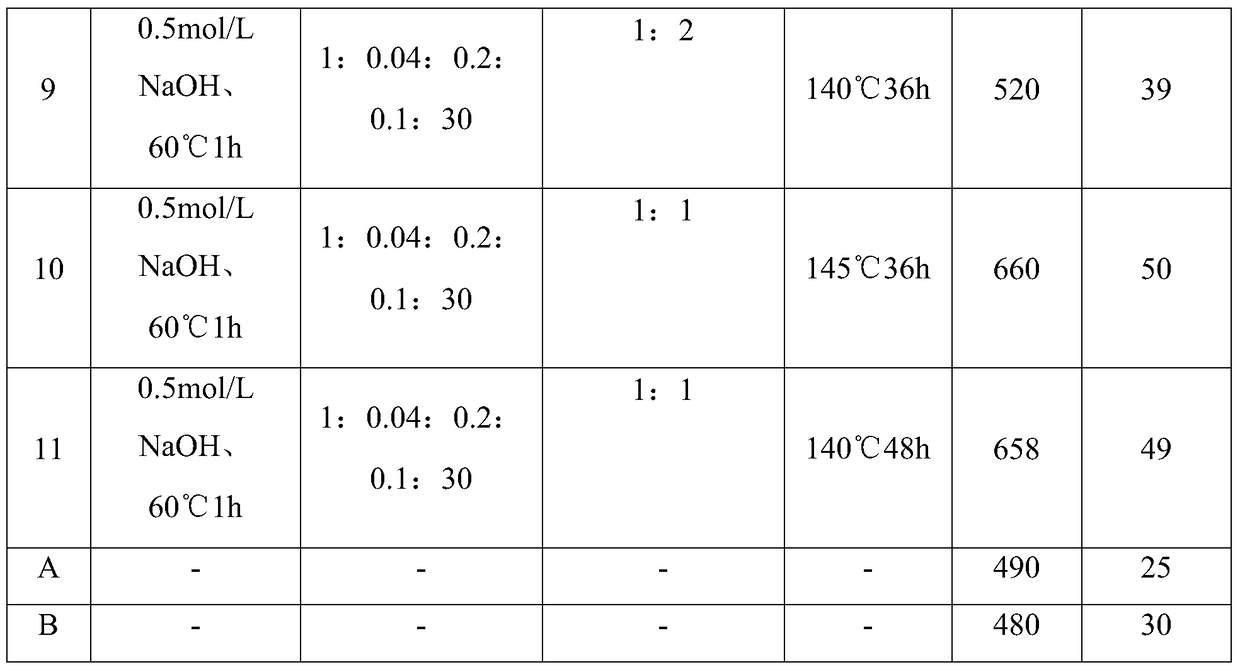

Embodiment 1

[0028] At 60°C, 20g Y molecular sieve was added to 0.5mol / L NaOH solution and stirred for 1h, then mixed with supplemented silica sol (SiO 2 Content 40%), NaAlO 2 Add them together to the tetraethylammonium hydroxide solution and stir, adjust the pH value of the solution to 11 with NaOH, continue to age and evaporate the solvent, and when the solid content is 25%, the molar composition is obtained as SiO 2 :Al 2 o 3 :TPA + :OH - :H 2 O=1:0.04:0.2:0.1:30, by weight ratio Y: (SiO 2 +Al 2 o 3 ) = 1:1 colloid, put it into a stainless steel kettle for crystallization, the crystallization temperature is 140°C, and the crystallization time is 36 hours. After crystallization, the slurry is cooled, filtered, washed, dried, and roasted at 550°C in an air atmosphere After 4 hours, the Y-Beta composite molecular sieve was obtained. The obtained molecular sieve was ammonium-exchanged and roasted into hydrogen form, and then pressed into tablets and crushed into 40-mesh granules fo...

Embodiment 2

[0030] At 60°C, add 20g Y molecular sieve into 0.8mol / L NaOH solution and stir for 1h, then mix with supplemented silica sol (SiO 2 Content 40%), NaAlO 2 Add them together to the tetraethylammonium hydroxide solution and stir, adjust the pH value of the solution to 11 with NaOH, continue to age and evaporate the solvent, and when the solid content is 25%, the molar composition is obtained as SiO 2 :Al 2 o 3 :TPA + :OH - :H 2 O=1:0.04:0.2:0.1:30, by weight ratio Y: (SiO 2 +Al 2 o 3) = 1:1 colloid, put it into a stainless steel kettle for crystallization, the crystallization temperature is 140°C, and the crystallization time is 36 hours. After crystallization, the slurry is cooled, filtered, washed, dried, and roasted at 550°C in an air atmosphere After 4 hours, the Y-Beta composite molecular sieve was obtained. The obtained molecular sieve was ammonium-exchanged and roasted into hydrogen form, and then pressed into tablets and crushed into 40-mesh granules for probe re...

Embodiment 3

[0032] At 80°C, add 20g Y molecular sieve into 0.5mol / L NaOH solution and stir for 1h, then mix with supplemented silica sol (SiO 2 Content 40%), NaAlO 2 Add them together to the tetraethylammonium hydroxide solution and stir, adjust the pH value of the solution to 11 with NaOH, continue to age and evaporate the solvent, and when the solid content is 25%, the molar composition is obtained as SiO 2 :Al 2 o 3 :TPA + :OH - :H 2 O=1:0.04:0.2:0.1:30, by weight ratio Y: (SiO 2 +Al 2 o 3 ) = 1:1 colloid, put it into a stainless steel kettle for crystallization, the crystallization temperature is 140°C, and the crystallization time is 36 hours. After crystallization, the slurry is cooled, filtered, washed, dried, and roasted at 550°C in an air atmosphere After 4 hours, the Y-Beta composite molecular sieve was obtained. The obtained molecular sieve was ammonium-exchanged and roasted into hydrogen form, and then pressed into tablets and crushed into 40-mesh granules for probe r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com