Nanorod assembled lithium manganese iron phosphate microspheres, composite material and preparation method thereof

A technology of lithium iron manganese phosphate and carbon composite material, applied in phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high energy consumption, long reaction time, etc. The effect of small diffusion distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1LiMnFePO 4 Preparation of microspheres and their composites

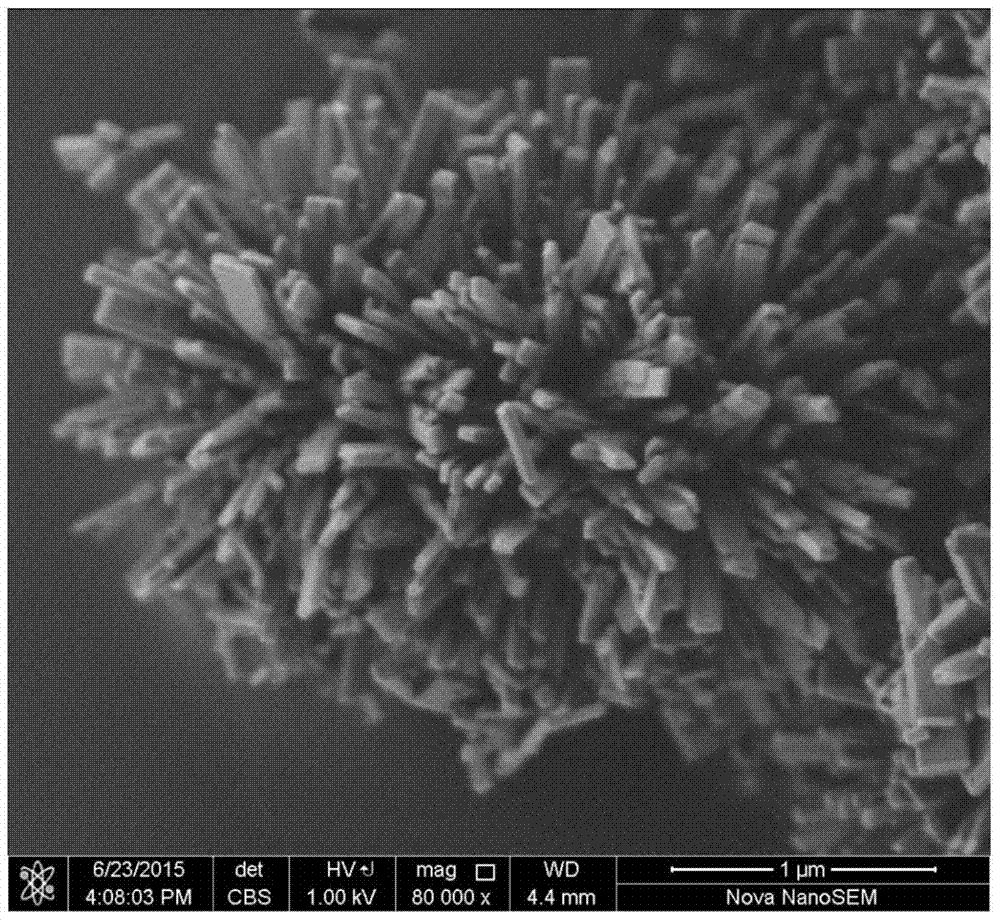

[0049] Aqueous / solvothermal synthesis of LiMnFePO with a diameter of about 2 μm 4 microspheres, which were used to assemble LiMnFePO 4 The diameter of the primary structure LiMnFePO4 nanorod of the microsphere is 20-50 nanometers.

[0050] The preparation method is as follows:

[0051] (1) Measure ethylene glycol and deionized water, and mix the two to obtain a mixed solvent of ethylene glycol and water with a volume ratio of 1:1.

[0052] (2) Weigh 0.169g manganese sulfate (MnSO 4 ·H 2 O) and 0.417g ferrous sulfate (FeSO 4 ·7H 2 (2) was dissolved successively in a mixed solvent of ethylene glycol and water with a total volume of 20ml to obtain solution A (ie the first mixed solution).

[0053] (3) Weigh 0.48g lithium sulfate (Li 2 SO 4 ·H 2 O), 0.2875g ammonium dihydrogen phosphate ((NH 4 )H 2 PO 4 ) and 0.21g potassium hydroxide (KOH), were dissolved successively in another solvent wi...

Embodiment 2

[0061] Water / Solvothermal Synthesis of LiMnFePO 4 Nanorod assembled microspheres, the diameter of the microspheres is not more than 1.5 microns, and the primary structure of the microspheres is LiMnFePO 4 The diameter of the nanorods is not greater than 50 nanometers.

[0062] Except that the following process is different from Example 1, other process steps are the same as Example 1, the difference is: the volume ratio of ethylene glycol and water in the mixed solvent prepared in step (1) is 1:1.5; Take by weighing 0.38g manganese sulfate and 0.07g ferrous sulfate; Take by weighing 0.16g lithium sulfate and 0.383g ammonium dihydrogen phosphate and 0.28g potassium hydroxide in step (3); In step (5), water / solvothermal reaction temperature at 160° C., and keep warm for 24 hours; in step (6), the organic carbon source is selected as sucrose, and the inert atmosphere is nitrogen.

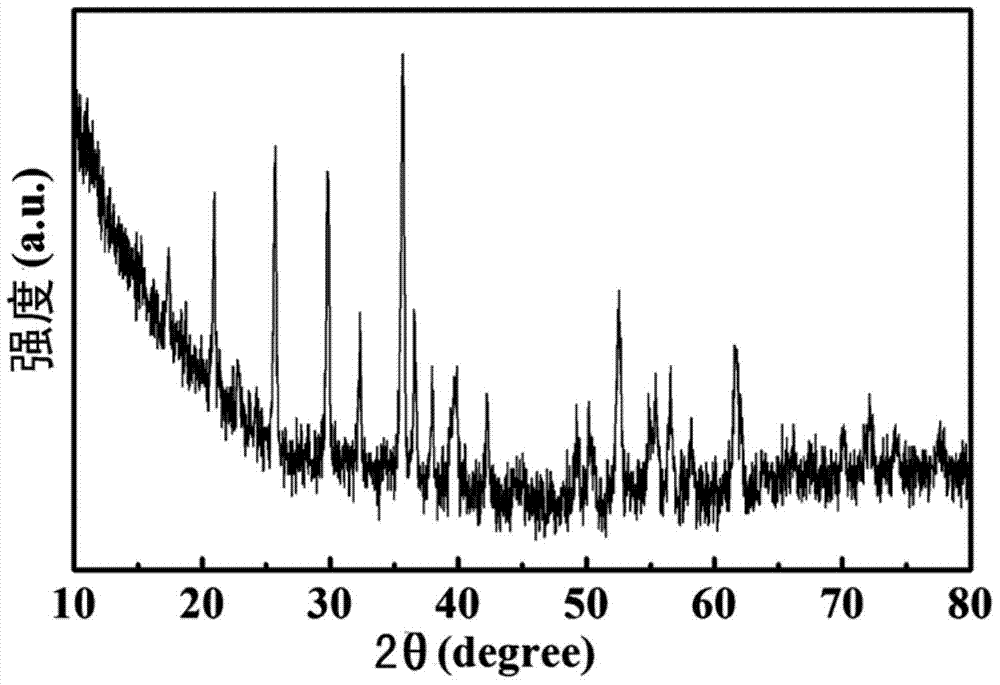

[0063] Figure 5 LiMnFePO prepared for this example 4 The X-ray diffraction (XRD) pattern of th...

Embodiment 3

[0066] Water / Solvothermal Synthesis of LiMnFePO 4 Nanorods assemble microspheres.

[0067] Except that the following process is different from Example 1, other process steps are the same as Example 1, the difference is: the volume ratio of ethylene glycol and water in the mixed solvent prepared in step (1) is 1:2; , the temperature of the water / solvothermal reaction is 240°C, and the temperature is kept for 8 hours.

[0068] LiMnFePO prepared from this example 4 The scanning electron microscope (SEM) picture of the microspheres shows that the LiMnFePO 4 The nanorod-assembled microspheres are 2 microns in diameter, and the primary structure of the microspheres is LiMnFePO 4 The diameter of the nanorod is 50 nanometers, the product has uniform appearance and good dispersion.

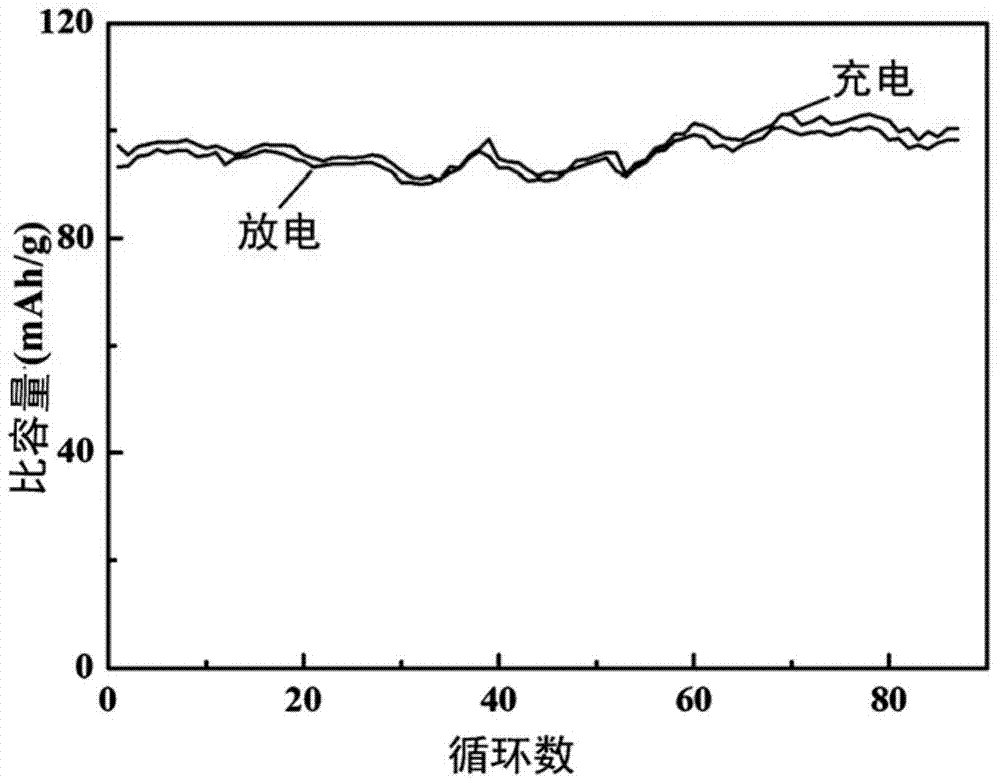

[0069] The charging and discharging performance test of the composite material prepared in this example: the lithium iron phosphate-carbon composite material prepared in this example is used as the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com