Plastic piston processing material for discharging of separating funnel for chemical laboratory test

A technology for separating funnel and processing materials, which is applied in the field of chemical glass instruments, can solve the problems of corroding gloves and reducing the safety of use, and achieves the effects of enhancing the processing formability, improving the safety of use, and ensuring the effect of liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Add 10 parts of chlorinated polyvinyl chloride and 3 parts of C9 petroleum resin to 20 parts of acrylonitrile-butadiene-styrene copolymer, and heat up to 125-130°C at a heating rate of 5°C / min and mix with heat 30min, then add 3 parts of organic fillers and 0.5 part of nano-titanium dioxide, and continue to heat and mix for 20min to obtain material I;

[0024] (2) Add 5 parts of polyvinyl chloride paste resin and 3 parts of fluorocarbon resin to 10 parts of ethylene-vinyl acetate copolymer, and heat up to 120-125 ° C at a heating rate of 5 ° C / min and mix for 20 minutes, then add 2 1 part of hydrogenated rosin glyceride and 2 parts of powdered acrylonitrile-butadiene rubber, continue to insulate and mix for 15min to obtain material II;

[0025] (3) Add material II, 2 parts of crospovidone, 1 part of asbestos wool and 1 part of molecular sieve raw powder to material I, mix well, and send the resulting mixture into a mixer, and mix it at 120-125 °C After refining f...

Embodiment 2

[0029] (1) Add 10 parts of chlorinated polyvinyl chloride and 3 parts of C9 petroleum resin to 20 parts of acrylonitrile-butadiene-styrene copolymer, and heat up to 125-130°C at a heating rate of 5°C / min and mix with heat 30min, then add 5 parts of organic fillers and 0.5 part of nano-titanium dioxide, and continue to heat and mix for 20min to obtain material I;

[0030] (2) Add 5 parts of polyvinyl chloride paste resin and 3 parts of fluorocarbon resin to 10 parts of ethylene-vinyl acetate copolymer, and heat up to 120-125 ° C at a heating rate of 5 ° C / min and mix for 20 minutes, then add 3 parts 1 part of hydrogenated rosin glyceride and 2 parts of powdered acrylonitrile-butadiene rubber, continue to insulate and mix for 15min to obtain material II;

[0031] (3) Add material II, 2 parts of crospovidone, 1 part of asbestos wool and 1 part of molecular sieve raw powder to material I, mix well, and send the resulting mixture into a mixer, and mix it at 120-125 °C After refi...

Embodiment 3

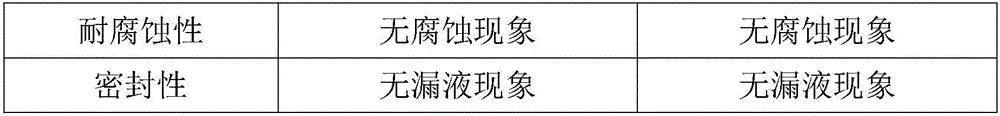

[0035] Utilize the material prepared in Example 1 and Example 2 to process and manufacture the plastic piston for discharging liquid in the separating funnel of small chemical industry test, and test its performance, the results are shown in Table 1.

[0036] The service performance of the plastic piston made by table 1 processing

[0037]

[0038]

[0039] Corrosion resistance test conditions: soak in 3wt% sodium chloride solution, 10wt% sulfuric acid solution, 10wt% sodium hydroxide solution for 24 hours each.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com