Low viscosity flame-retardant room temperature vulcanized foam silicone rubber and preparation method thereof

A room temperature vulcanization, low-viscosity technology, applied in plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of flame retardancy and other problems that have not been mentioned, and achieve convenient construction, excellent high temperature and low temperature resistance, and easy flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

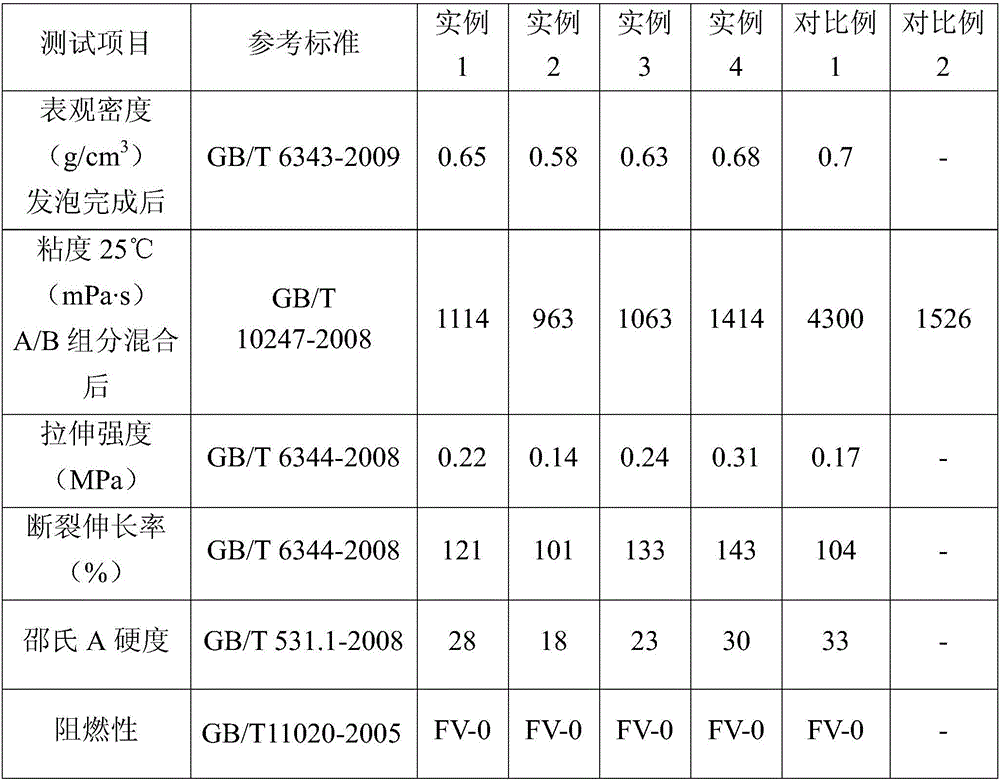

Examples

Embodiment 1

[0061] A component:

[0062] α,ω-Dihydroxypolydimethylsiloxane, viscosity 700mPa·s, 100 parts;

[0063] The modified aluminum hydroxide superfine powder that stearic acid carries out surface treatment, particle diameter 1500 orders, 50 parts;

[0064] Quartz sand, particle size 800 mesh, 20 parts;

[0065] Methylphenyl silicone oil (10% molar content of phenyl), viscosity 100mPa·s, 10 parts;

[0066] Vinyl-terminated silicone oil, viscosity 300mPa·s, 25 parts;

[0067] Pt catalyst: Karstedt method platinum-vinyl siloxane 3000ppm, 0.5 parts;

[0068] Expanded graphite, 4 parts;

[0069] B component:

[0070] α,ω-Dihydroxypolydimethylsiloxane, viscosity 1500mPa·s, 100 parts;

[0071] Hydroxyl-terminated silicone oil, viscosity 60mPa·s, 10 parts;

[0072] Stearic acid is carried out the superfine powder of modified aluminum hydroxide after surface treatment, particle diameter 1500 orders, 50 parts;

[0073] Methylphenyl silicone oil (10% molar content of phenyl), viscosit...

Embodiment 2

[0085] A component:

[0086] α,ω-Dihydroxypolydimethylsiloxane, viscosity 700mPa·s, 100 parts;

[0087] Stearic acid is carried out the superfine powder of modified aluminum hydroxide after surface treatment, particle diameter 1500 orders, 50 parts;

[0088] Calcium carbonate, particle size 1500 mesh, 20 parts;

[0089] Methylphenyl silicone oil, the molar content of phenyl is 10%, the viscosity is 150mPa·s, 10 parts;

[0090] Vinyl-terminated silicone oil, viscosity 300mPa·s, 25 parts;

[0091] Pt catalyst: Karstedt method platinum-vinyl siloxane 3000ppm, 0.6 parts;

[0092] Expanded graphite, 6 parts;

[0093] B component:

[0094] α,ω-Dihydroxypolydimethylsiloxane, viscosity 700mPa·s, 100 parts;

[0095] Hydroxyl-terminated silicone oil, viscosity 60mPa·s, 5 parts;

[0096] Methylphenyl silicone oil, the molar content of phenyl is 10%, the viscosity is 150mPa·s, 5 parts;

[0097] Stearic acid is carried out the superfine powder of modified aluminum hydroxide after s...

Embodiment 3

[0109] A component:

[0110] α,ω-Dihydroxypolydimethylsiloxane, viscosity 1500mPa·s, 100 parts;

[0111] Sodium stearate carries out the modified magnesium hydroxide superfine powder after surface treatment, particle diameter 1200 orders, 50 parts;

[0112] Zinc oxide, particle size 2000 mesh, 15 parts;

[0113] Methylphenyl silicone oil, the molar content of phenyl is 15%, the viscosity is 60mPa·s, 15 parts;

[0114] Vinyl-terminated silicone oil, viscosity 500mPa·s, 25 parts;

[0115] Pt catalyst: Karstedt method platinum-vinyl siloxane 2800ppm, 0.5 parts;

[0116] Zinc borate, 10 parts;

[0117] B component:

[0118] α,ω-Dihydroxypolydimethylsiloxane, viscosity 1500mPa·s, 100 parts;

[0119] Hydroxyl-terminated silicone oil, viscosity 60mPa·s, 5 parts;

[0120] Methylphenyl silicone oil, the molar content of phenyl is 15%, the viscosity is 60mPa·s, 10 parts;

[0121] Sodium stearate carries out the modified magnesium hydroxide superfine powder after surface treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com