Method for improving lignocellulose enzymolysis efficiency by lignocellulose pretreatment through ultrasonic-microwave synchronously-assisted ionic liquid system

A lignocellulose and lignocellulose technology is applied in the field of resource utilization of lignocellulose biomass, which can solve the problems of high cost and high energy consumption, and achieve the effects of reducing dosage, saving resources and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

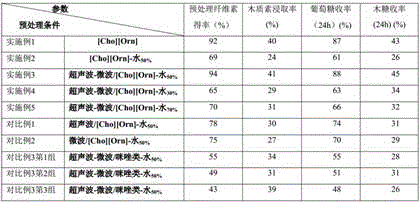

Examples

Embodiment 1

[0027] Example 1: Using [Cho][Orn] to pretreat rice straw to improve its enzymatic hydrolysis efficiency.

[0028] a) Pretreatment: Accurately weigh 0.25 g rice straw powder (150-350 μm) and 4 g [Cho][Orn], put them together in a 20 mL Erlenmeyer flask, stir at 95°C for 12 hours; then cool to room temperature , take 0.5 mL supernatant, and use UV spectrophotometry to measure lignin extraction rate.

[0029] b) Subsequent sample preparation: Slowly add NaOH solution (0.1mol / L) 1 times the volume of the ionic liquid to the pretreatment system to dilute, filter, and then wash the filter residue 4 times with 2 times the volume of deionized water until the supernatant is colorless , and the filter residue was dried at 60°C to obtain the pretreated rice straw sample.

[0030] c) Enzyme hydrolysis: Accurately weigh 0.05 g of the above-mentioned pretreated rice straw, place it in a 50 mL Erlenmeyer flask, add 20 mL citrate buffer (50 mmol / L, pH 4.8) and 45 U commercial Cellulase was...

Embodiment 2

[0031] Example 2: Using [Cho][Orn]-water mixed system to pretreat rice straw to improve its enzymatic hydrolysis efficiency.

[0032]a) Pretreatment: Accurately weigh 0.25g of rice straw powder (150-350μm), 2g of [Cho][Orn] ionic liquid and 2g of deionized water, put them together in a 20mL Erlenmeyer flask with stopper, at 95℃ The mixture was stirred for 12 hours, and then cooled to room temperature; 0.5 ml of the supernatant was taken to determine the lignin extraction rate by ultraviolet spectrophotometry.

[0033] b) Subsequent sample preparation: Slowly add 1 times the volume of ionic liquid NaOH solution (0.1mol / L) to the pretreatment system to dilute, filter, and then wash the filter residue 4 times with 2 times the volume of deionized water until the supernatant is colorless , and the filter residue was dried at 60°C to obtain the pretreated rice straw sample.

[0034] c) Enzymatic hydrolysis: Accurately weigh 0.05 g of the above-mentioned pretreated rice straw, place...

Embodiment 3

[0035] Example 3: Ultrasonic-microwave-assisted [Cho]Orn-water mixed system (50%:50%) pretreats rice straw to improve its enzymatic hydrolysis efficiency.

[0036] a) Pretreatment: Accurately weigh 0.25 g of rice straw powder (150–350 μm), 2 g of [Cho][Orn] ionic liquid and 2 g of deionized water, put them together in a 20 mL Erlenmeyer flask, and place them in an ultrasonic-microwave In a synergistic reactor (Nanjing Xianou Instrument Manufacturing Co., Ltd.); the setting conditions are: ultrasonic frequency 25KHZ, power 800W; microwave frequency 2450 MHZ, power 1000W, and keep at 95°C for 6 hours. After cooling to room temperature, 0.5 ml of the supernatant was taken to determine the lignin extraction rate by ultraviolet spectrophotometry.

[0037] b) Subsequent sample preparation: Slowly add NaOH solution (0.1 mol / L) 1 times the volume of the ionic liquid to the pretreatment system to dilute, filter, and then wash the filter residue 4 times with 2 times the volume of deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com