Construction and application of multilevel structure ZnO@Au@ZIF-8 compound photoelectrode

A photoelectrode and composite material technology, applied in the direction of electrodes, electrode shapes/types, electrolytic components, etc., can solve problems such as low conductivity, loss of active sites, and decline in catalytic activity, and achieve high yield, easy implementation, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

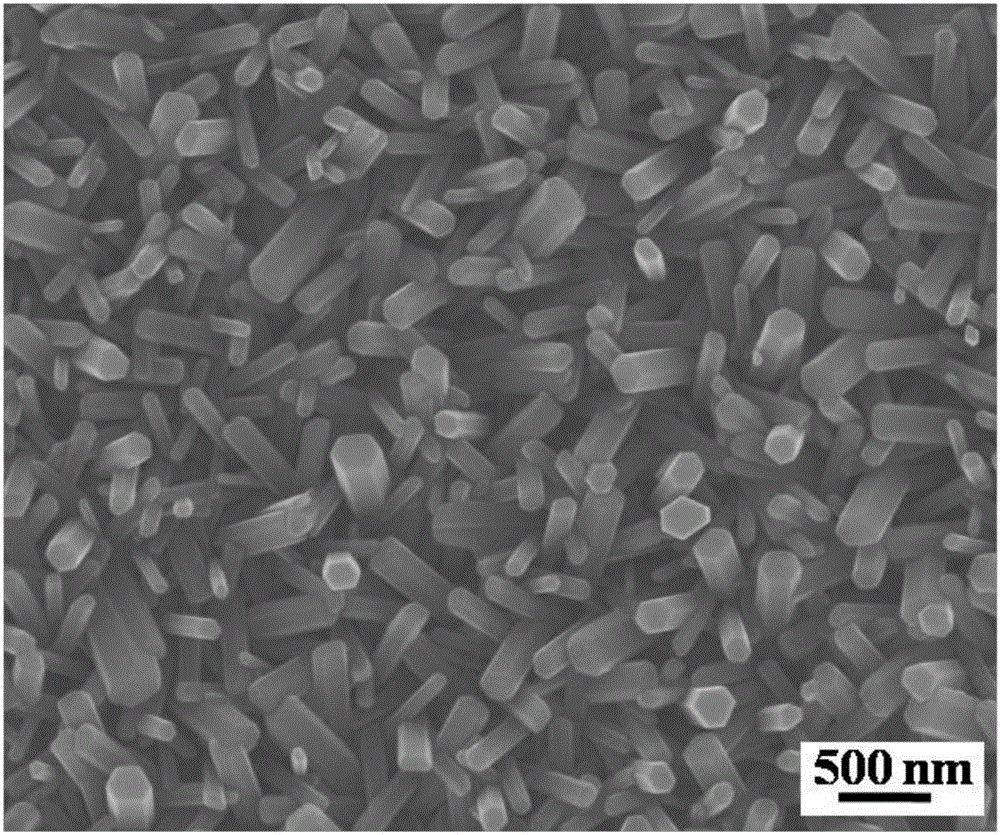

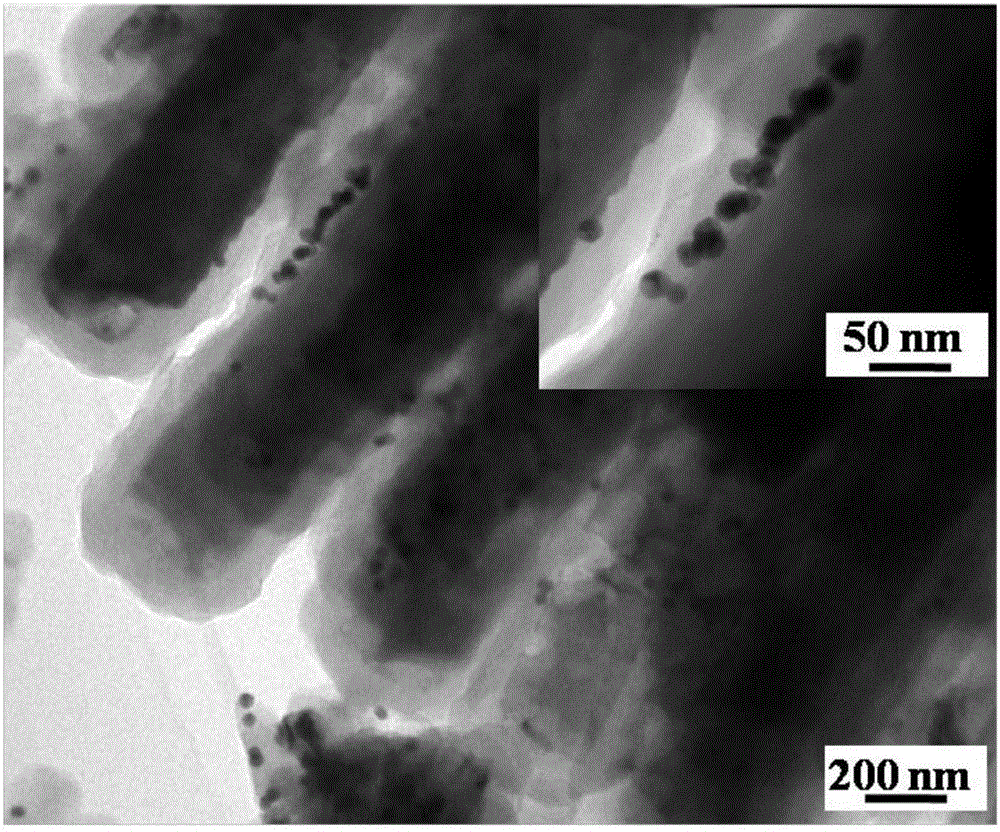

[0019] The first step: the FTO glass was pretreated with acetone, ethanol and water ultrasonically for 10 minutes, and the ZnO electrode was prepared by a simple hydrothermal method. Specific method: it dissolves zinc acetate in absolute ethanol to prepare 5mM zinc acetate ethanol solution. The above solution was spin-coated onto the pretreated FTO to obtain a layer of seed crystal film, and then annealed at 350°C for 30 minutes. The FTO growing ZnO seed crystals was tilted in a polytetrafluoroethylene reactor filled with the same molar volume of 50mM zinc nitrate and 50mM cyclohexamethylenetetramine, the reaction temperature was 80°C, and the reaction time was 5 hours. After cooling to room temperature, the prepared ZnO electrode was rinsed with deionized water and dried in air.

[0020] Step 2: Dissolve 0.01 g of chloroauric acid tetrahydrate into 15 ml of methanol and 100 ml of water, heat the mixed solution to 60° C. and stir until brown-red to obtain solution B.

[0021...

Embodiment 2

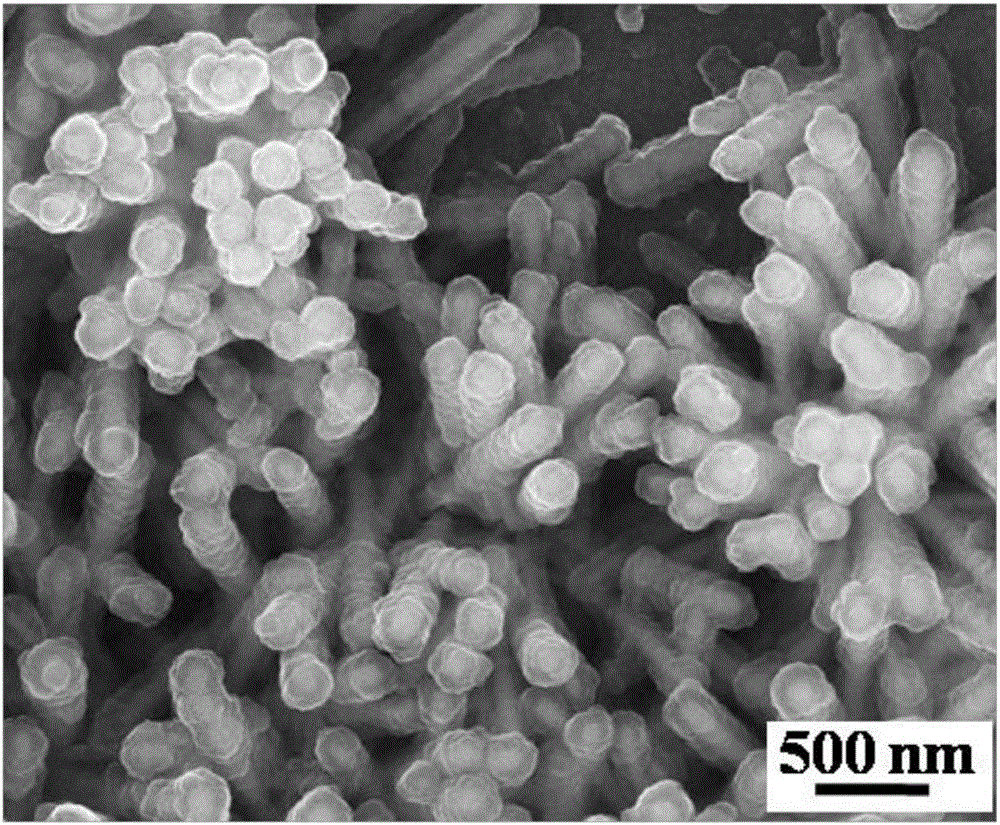

[0023] The FTO was pretreated with acetone, ethanol and water ultrasonic for 10 minutes, respectively, and the ZnO electrode was obtained by a simple hydrothermal method. The specific method: the zinc acetate is dissolved in absolute ethanol to prepare a 10mM zinc acetate ethanol solution. The above solution was spin-coated onto the pretreated FTO to obtain a layer of seed crystal film, and then annealed at 350°C for 30 minutes. The FTO growing ZnO seed crystals was tilted in a polytetrafluoroethylene reactor filled with the same molar volume of 60mM zinc nitrate and 60mM cyclohexamethylenetetramine, the reaction temperature was 95°C, and the reaction time was 12 hours. After cooling to room temperature, the prepared ZnO electrode was rinsed with deionized water and dried in air.

[0024] Step 2: Dissolve 0.1 g of chloroauric acid tetrahydrate into 15 ml of methanol and 100 ml of water, heat the mixed solution to 70° C. and stir until brown-red to obtain solution B.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com