An integrated device and method for a high-sodium coal heating removal furnace and a coal-fired power station

A technology for coal-fired power plants and integrated devices, applied in combustion methods, steam engine devices, steam generating devices, etc., can solve problems such as increasing the unreliability of system operation, affecting independence and reliability, destroying the independence of the original system, and achieving high efficiency Effects of rapid sodium removal, reduced system complexity, and avoidance of large-scale retrofits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

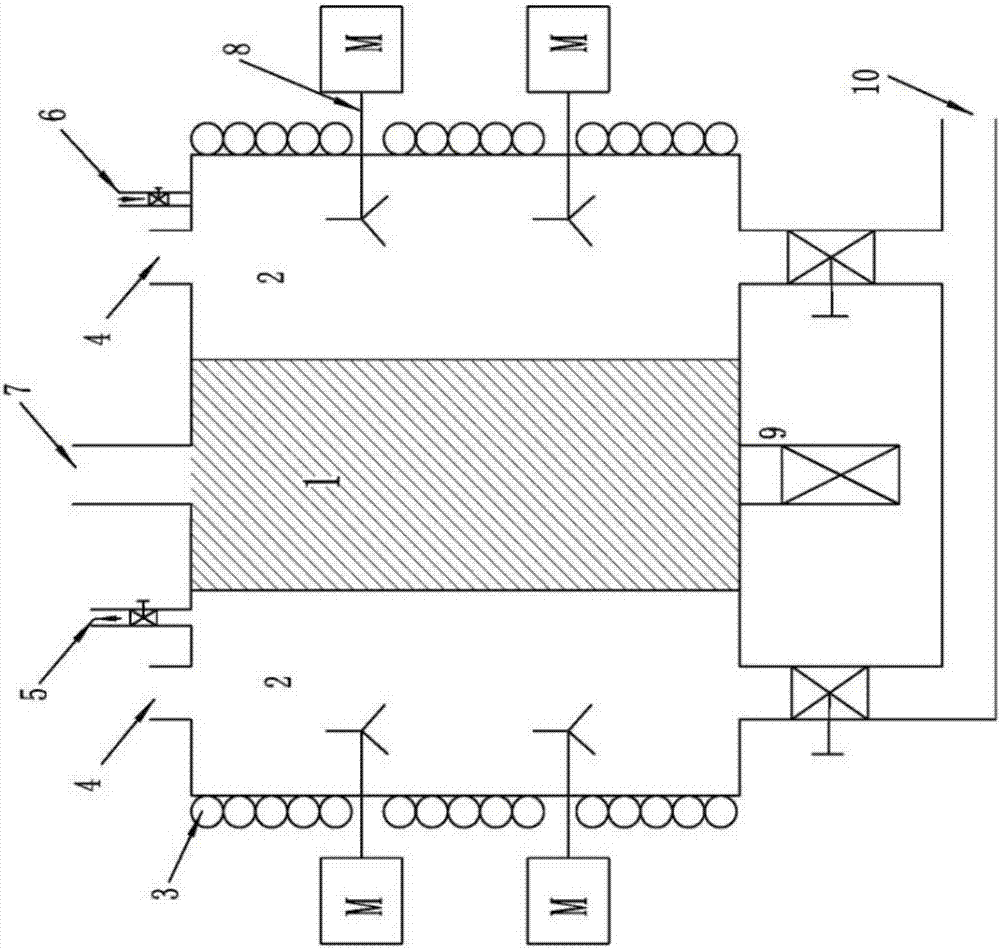

[0042] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

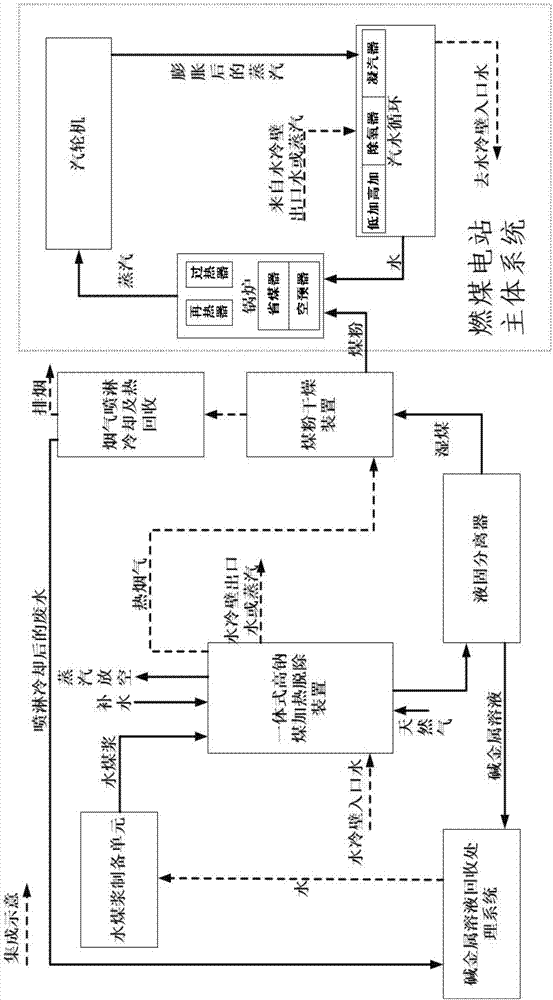

[0043] Such as figure 1 Shown is an integrated system of an integrated high-sodium coal heating and removal furnace and a coal-fired power station. The integrated system includes two major systems, namely a high-sodium coal heating and removal furnace system and a coal-fired power station system.

[0044] further as figure 1 As shown, the high-sodium coal heating and removal furnace system includes a high-sodium coal heating and removal furnace, a liquid-solid separator, a coal-water slurry preparation unit, an alkali metal solution recovery treatment system, a pulverized coal drying device, and a flue gas spray cooling and a heat recovery device, the upper end of the high-sodium coal heating removal furnace is connected to the coal water slurry preparation unit, the lower part is connected to the liquid-solid separator, one end of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com