Optimization method for separating target in complex mixture by simulated moving bed chromatography

A technology of simulated moving bed and chromatographic separation, applied in the field of optimization of targets in complex mixtures separated by simulated moving bed chromatography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

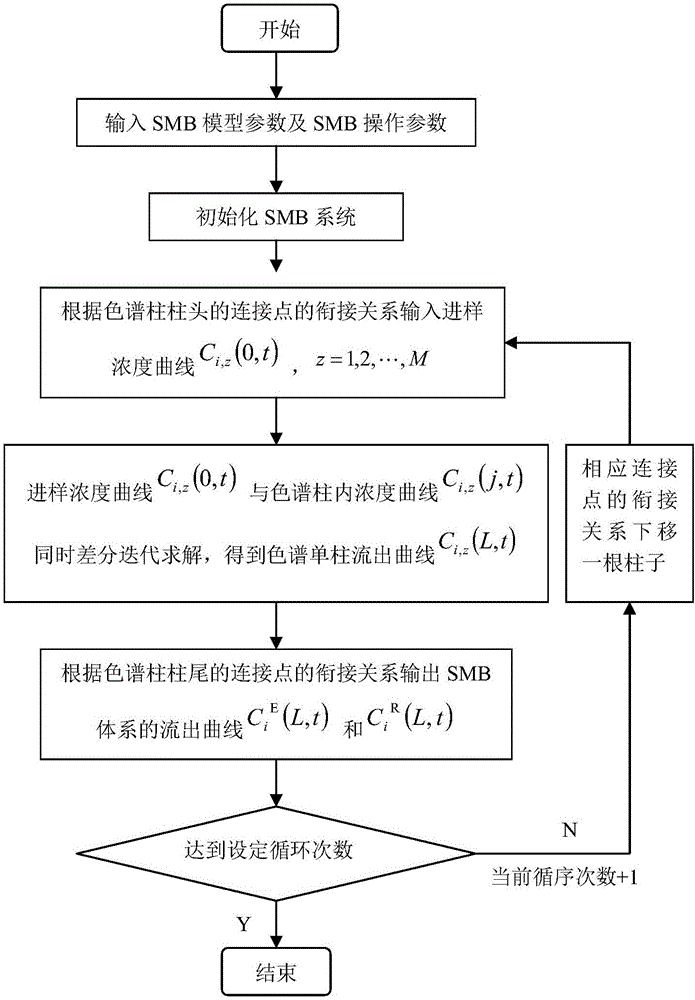

Method used

Image

Examples

Embodiment

[0088] An optimized method for the separation of rebaudioside A (RA) from stevia rebaudiana extract by SMB chromatography.

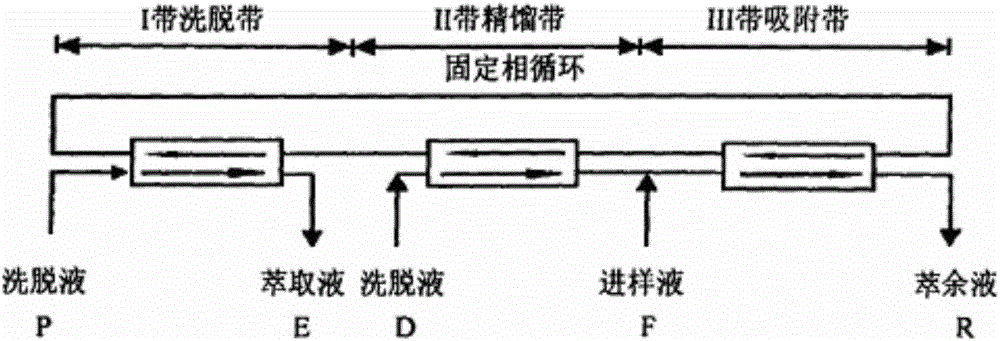

[0089] SMB chromatographic system used: Working mode: 1-1-2, I band is independent, see figure 2 ; 4 chromatographic columns, the chromatographic column specifications are D × L = i0mm × 100mm; stationary phase: C18, 40 ~ 60 μ m; mobile phase: ethanol-water, proportioning 1: 1; chromatographic separation temperature: room temperature;

[0090] HPLC detection conditions: analytical column: 4.6mm * 250mm (C18, 5 μm, Agilent, U.S.A.), mobile phase: the ratio of chromatographic acetonitrile and sodium dihydrogen phosphate buffer solution of pH=2.6 is 32 / 68 (v / v), flow velocity 1.0ml / min, measurement wavelength 213nm, measurement temperature 30°C.

[0091] The optimization method includes the following steps:

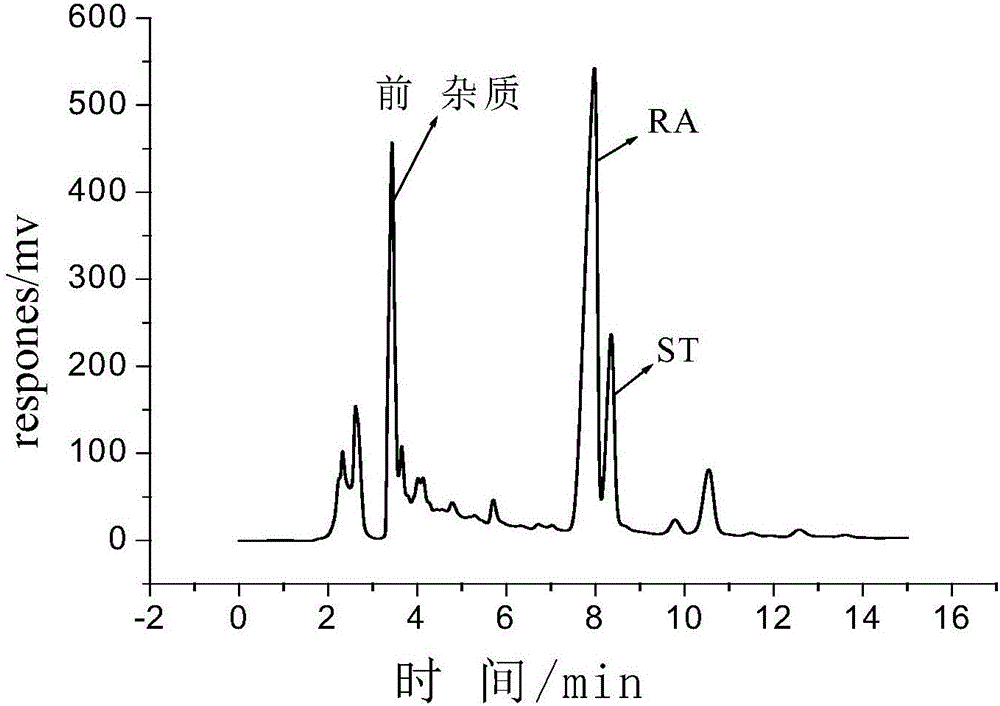

[0092] (1) prepare the sample liquid of stevia extract by the mobile phase ethanol of SMB chromatogram and the proportioning of water, measure the ...

Embodiment 2

[0139] Adopt the orthogonal design optimization method to optimize the SMB chromatographic system operating parameters with the SMB chromatographic model, and other steps and conditions are all with embodiment 1; L 9 (3 3 ) orthogonal table and SMB model simulation calculation results are shown in Table 2, and the experimental point with higher production efficiency (g product / ml mobile phase) optimized in Table 2 is, That is, the flow rate of pump D is 0.6 ml / min, the flow rate of pump F is 0.2 ml / min, and the injection concentration is 10 mg / ml.

[0140] Table 2, L 9 (3 3 ) orthogonal table and SMB chromatographic model simulation calculation results

[0141]

[0142] The separation experiment was carried out under the conditions optimized by the SMB chromatographic model, and the results are shown in Table 3.

[0143] Table 3, SMB chromatographic model calculation simulation results and SMB separation experiment results

[0144]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com