An Optimization Method for 1×n Demultiplexer/Combiner

An optimization method and combiner technology, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as high production process accuracy requirements and complex structure, and achieve the effect of avoiding poor optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

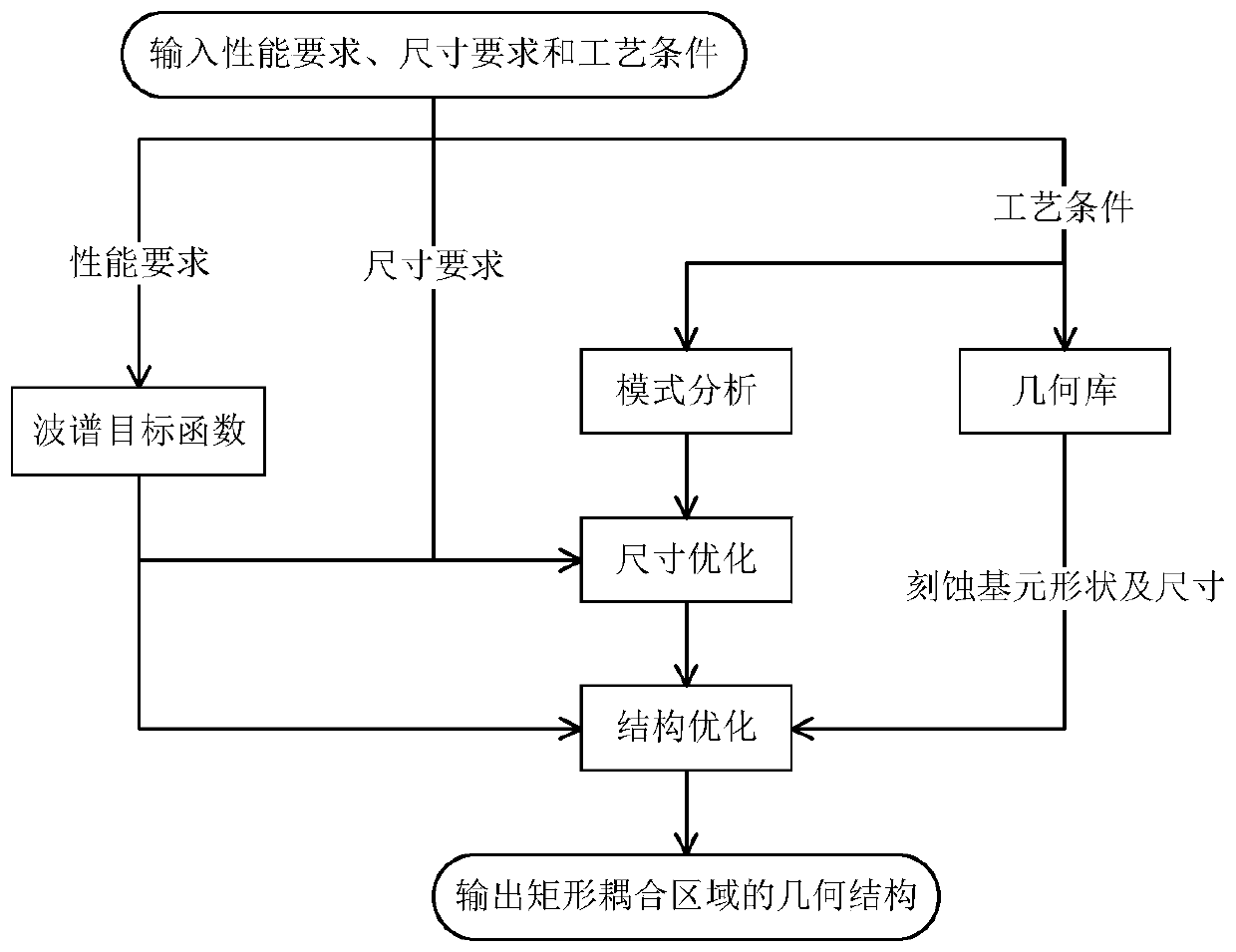

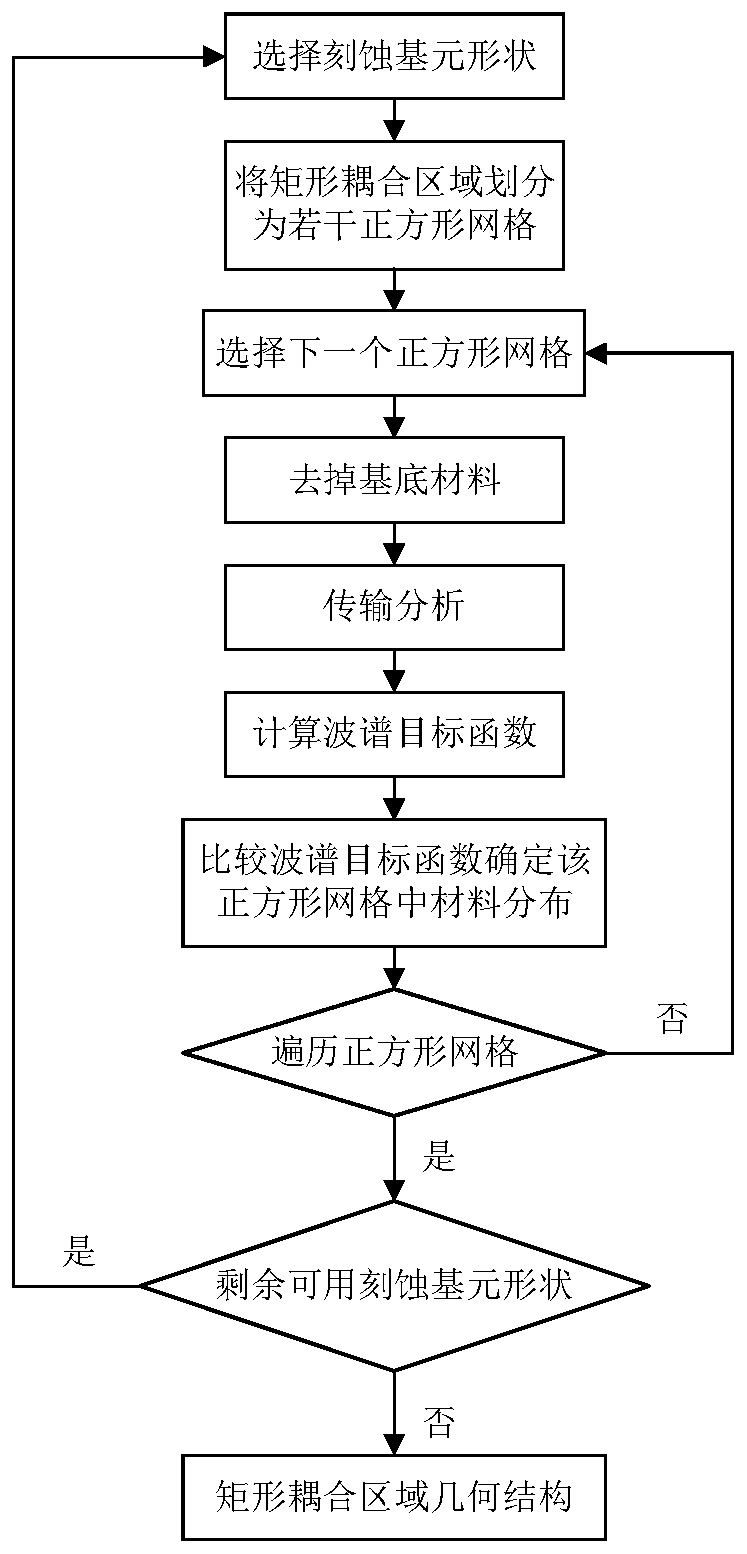

[0033] A method for optimizing a 1×N demultiplexer / combiner, which is applied to the optimization of a 1×21310nm / 1550nm demultiplexer / combiner, comprising the following steps:

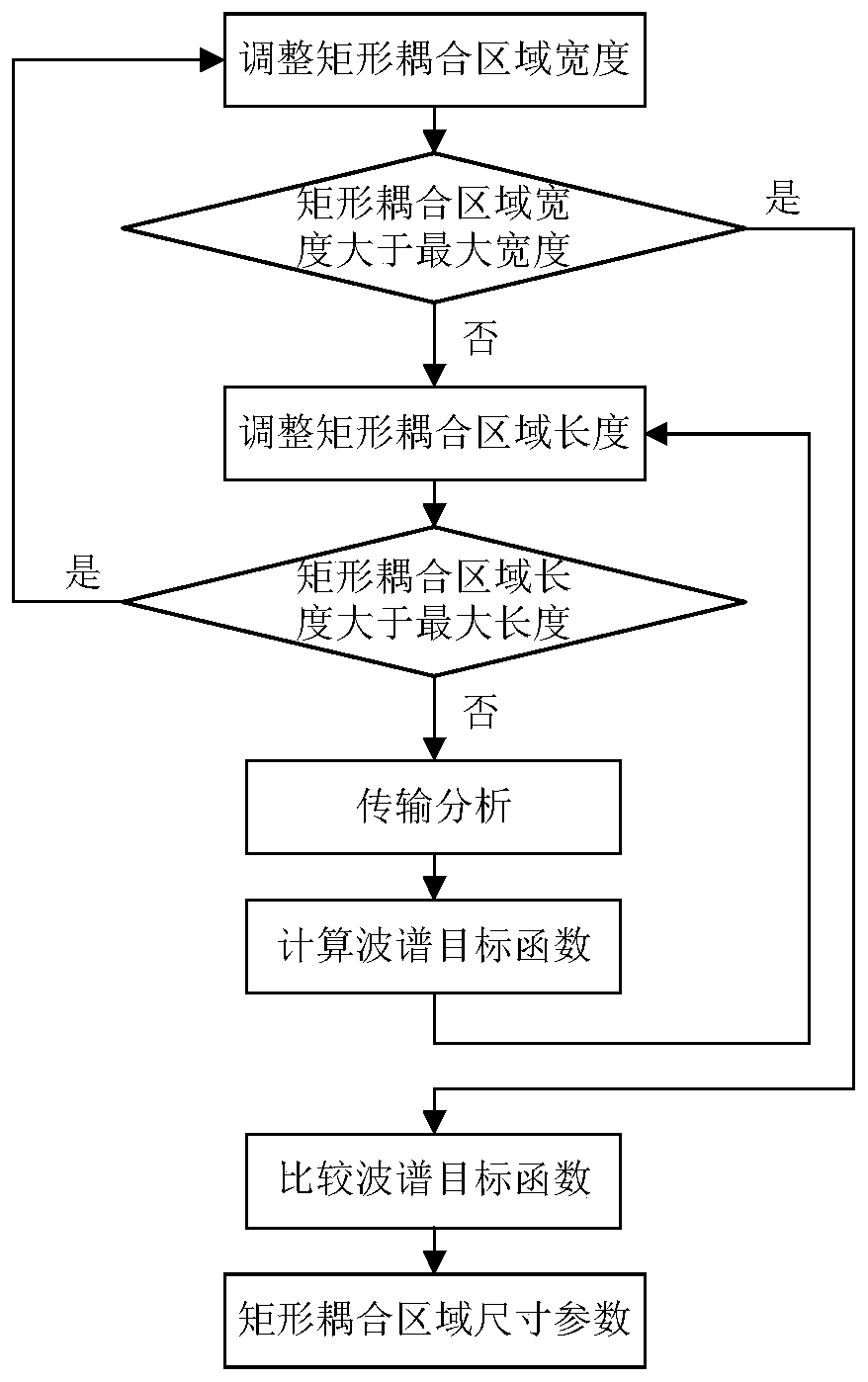

[0034] Step 1 Determine the performance requirements, size requirements and process conditions of the 1×21310nm / 1550nm wavelength demultiplexer, the performance requirements are at 1310nm and 1550nm wavelengths, when the power input to the input port is unit power, the output to the output port 1 target power a 11 and a 12 1 and 0, respectively, the target power output to output port 2 a 21 and a 22 are 0 and 1 respectively; the size requirement is the maximum size of the rectangular coupling area, where the maximum length L of the rectangular coupling area max 5000μm, maximum width W max is 50 μm; the process conditions include two parts, the first part is the refractive index of each part of the waveguide, where the substrate refractive index n s is 1.4444, the core refractive index n o is 1.46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com