Creep feed using ideal fat raw materials to improve production performance of suckling piglets and preparation method thereof

A technology for production performance and suckling piglets, which is applied in the field of feed, can solve problems such as not easy to use, not applicable, and insoluble in water, etc., and achieve the effect of improving utilization efficiency, increasing utilization efficiency, and increasing daily weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

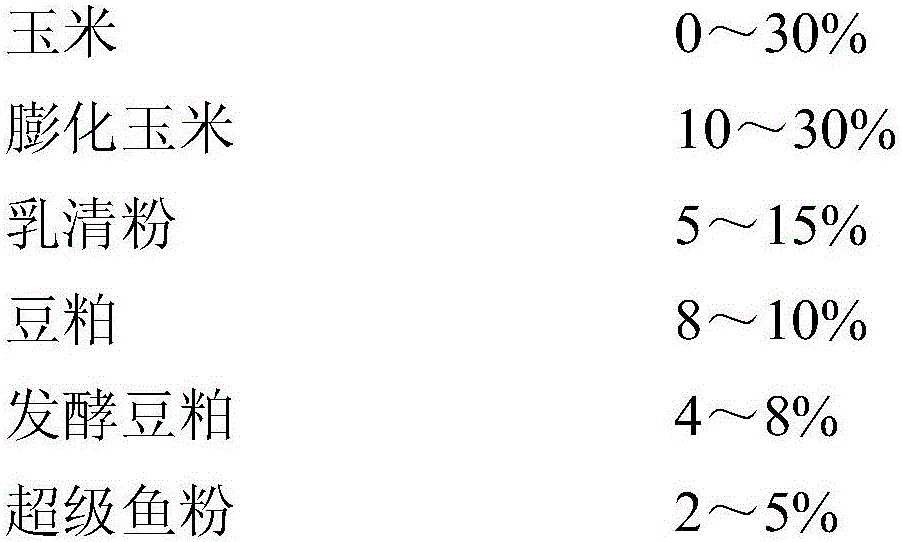

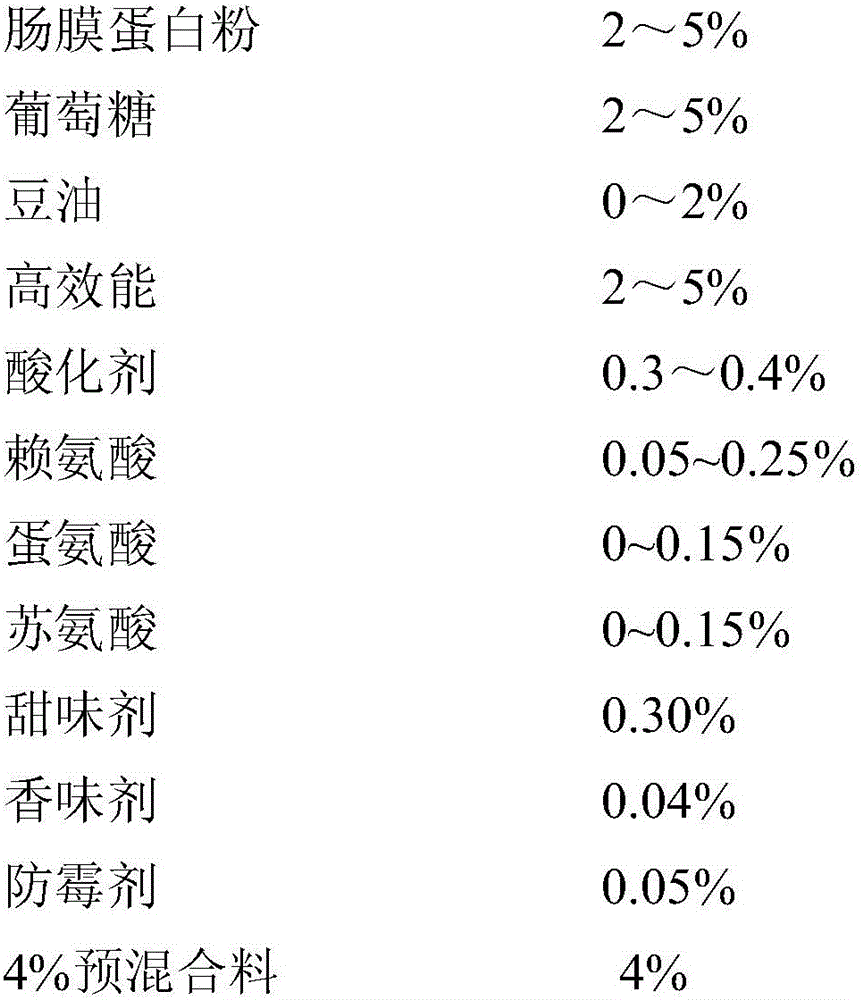

[0033] 1. Teach tank material formula:

[0034]

[0035]

[0036] All the above-mentioned raw materials can be purchased in the raw material market except high potency.

[0037] High performance is prepared by the following process:

[0038] ① In an emulsification tank, mix 2 parts of oleic acid, 8 parts of linoleic acid, 2 parts of linolenic acid, 10 parts of palm oil, 15 parts of β vegetable oil, 5 parts of stearic acid, 1 part of vitamin E, and 0.2 parts of lipase. Mix evenly and heat to 70°C; ② Add 1.5 parts of lactic acid monoglyceride and 40 parts of water, emulsify and homogenize for 10 minutes, rotate at 2500 rpm, and power 2.2KW / h to obtain emulsification that meets the design requirements Vegetable oil; ③Spray emulsified vegetable oil into a mixer with 55 parts of esterified porous starch added in advance, and after mixing for 2 minutes, a solid fat product with good fluidity and high efficiency can be obtained.

[0039] Two, the preparation method of above-m...

Embodiment 2

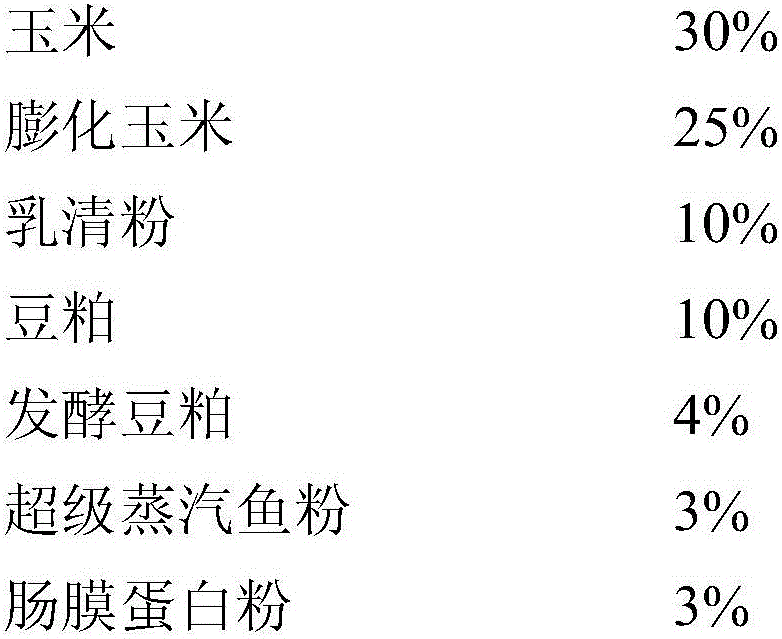

[0049] 1. Teach tank material formula:

[0050]

[0051]

[0052] All the above-mentioned raw materials can be purchased in the raw material market except high potency.

[0053] High performance is prepared by the following process:

[0054] ① In an emulsification tank, mix 2.5 parts of oleic acid, 6 parts of linoleic acid, 2.5 parts of linolenic acid, 8 parts of palm oil, 18 parts of β vegetable oil, 4 parts of stearic acid, 0.8 parts of vitamin E, and 0.3 parts of lipase, and mix Mix evenly and heat to 75°C; ② Add 2 parts of monoglyceride lactate and 46.0 parts of water, emulsify and homogenize for 15 minutes, rotate at 2000 rpm, and power 2.0KW / h to obtain emulsification that meets the design requirements Vegetable oil; ③Spray the emulsified vegetable oil into the mixer with 53 parts of esterified porous starch added in advance, and after mixing for 1.5 minutes, a solid fat product with good fluidity and high efficiency can be obtained.

[0055] Two, the preparation...

Embodiment 3

[0065] 1. Teach tank material formula:

[0066]

[0067] All the above-mentioned raw materials can be purchased in the raw material market except high potency.

[0068] High performance is prepared by the following process:

[0069] ① In an emulsification tank, mix 1.5 parts of oleic acid, 9 parts of linoleic acid, 3 parts of linolenic acid, 12 parts of palm oil, 16 parts of β vegetable oil, 3 parts of stearic acid, 1.5 parts of vitamin E and 0.1 part of lipase, and mix Mix evenly and heat to 55°C; ② Add 1.8 parts of lactic acid monoglyceride and 33.5 parts of water, emulsify and homogenize for 12 minutes, rotate at 2200 rpm, and power 2.1KW / h to obtain emulsification that meets the design requirements Vegetable oil; ③Spray the emulsified vegetable oil into the mixer with 55.5 parts of esterified porous starch added in advance, and after mixing for 1 minute, a solid fat product with good fluidity and high efficiency can be obtained.

[0070] Two, the preparation method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com