Method for modifying ZSM-5 molecular sieve through organophosphorous compound

A ZSM-5, molecular sieve technology, used in organic chemistry, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reduced catalytic performance, easy deactivation, poor hydrothermal stability, etc. Aluminium, the effect of excellent selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example illustrates the process of modifying the HZSM-5 molecular sieve with the organophosphorus compound of the present invention.

[0035] Weigh tetrabutylphosphorus hydroxide (Sinopharm Chemical Reagent Co., Ltd., analytically pure, TBPOH content 40%, the same below) and add deionized water, then add 54.0g of HZSM-5 molecular sieve, dip and stir to form P 2 o 5 The mixture is 3.5wt%, and the mixture is dried and calcined, and the product is recovered to obtain the modified HZSM-5 molecular sieve of the present invention, denoted as P-Z-2.

[0036] The crystallinity of P-Z-2 was 83.5.

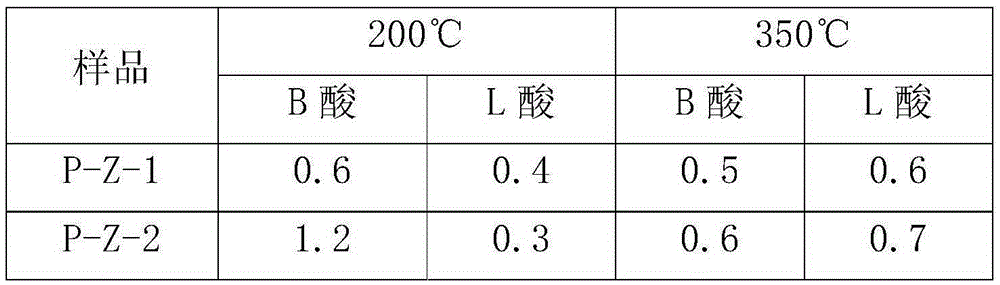

[0037] The acidity data are shown in Table 1, and Table 1 shows that P-Z-2 is hydrothermally treated at 100% water vapor and 800°C for 17 hours, and the amount of acid centers is measured by pyridine infrared spectroscopy.

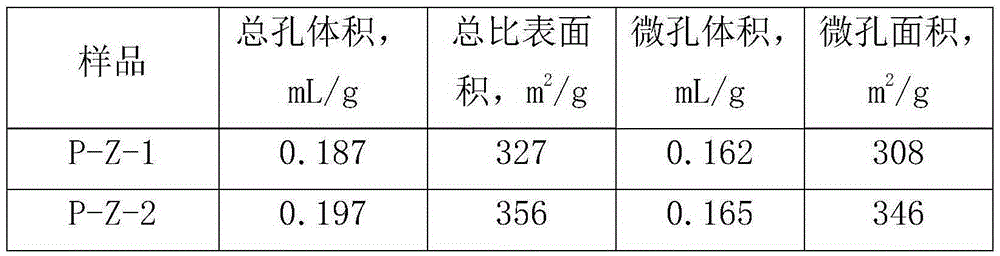

[0038] The pore structure data are shown in Table 2. Table 2 illustrates the pore structure data of P-Z-2 after hydrothermal treatment at 100% water vapor...

Embodiment 2

[0051] This example illustrates the process of modifying the HZSM-5 molecular sieve with the organophosphorus compound of the present invention.

[0052] Weigh tetrabutylphosphorus hydroxide (Sinopharm Chemical Reagent Co., Ltd., analytically pure, TBPOH content 40%, the same below) and add deionized water, then add 54.0g of HZSM-5 molecular sieve, dip and stir to form P 2 o 5 The mixture is 5.5 wt%, and the mixture is dried and calcined, and the product is recovered to obtain the modified HZSM-5 molecular sieve of the present invention, which is marked as P-Z-4.

[0053] The crystallinity of P-Z-4 was 85.3.

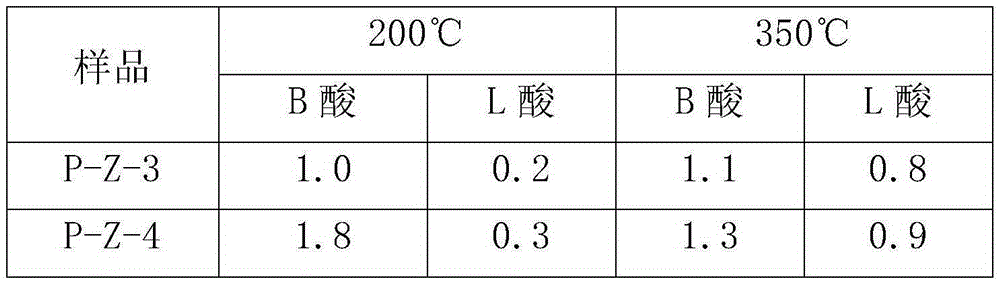

[0054] The acidity data are shown in Table 3, and Table 3 shows that P-Z-4 is hydrothermally treated at 100% water vapor and 800°C for 17 hours, and the amount of acid centers is measured by pyridine infrared spectroscopy.

[0055] The pore structure data are shown in Table 4. Table 4 illustrates the pore structure data of P-Z-4 after hydrothermal treatment at 100% wa...

Embodiment 3

[0068] This example illustrates the process of modifying the HZSM-5 molecular sieve with the organophosphorus compound of the present invention.

[0069] Weigh tetrabutylphosphorus hydroxide and add deionized water, then add 54.0g of HZSM-5 molecular sieve, impregnate and stir to form P 2 o 5 The mixture was 7.0 wt%, and the mixture was dried and calcined, and the product was recovered to obtain the modified HZSM-5 molecular sieve of the present invention, which was designated as P-Z-6.

[0070] The crystallinity of P-Z-6 was 86.0.

[0071] The acidity data are shown in Table 5, and Table 5 shows that P-Z-6 is hydrothermally treated at 100% water vapor and 800°C for 17 hours, and the amount of acid centers is measured by pyridine infrared spectroscopy.

[0072] The pore structure data are shown in Table 6. Table 6 illustrates the pore structure data of P-Z-6 after hydrothermal treatment at 100% water vapor and 800 °C for 17 h.

[0073] table 5

[0074]

[0075] Table 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com