Engine suspension rubber material and preparation method thereof

An engine mount and rubber compound technology is applied in the field of engine mount compound and the preparation of the engine mount compound, which can solve the problems of increased stiffness, collapse, and adverse effects of rubber products, so as to improve fatigue durability, reduce The effect of reducing durability and improving dynamic fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

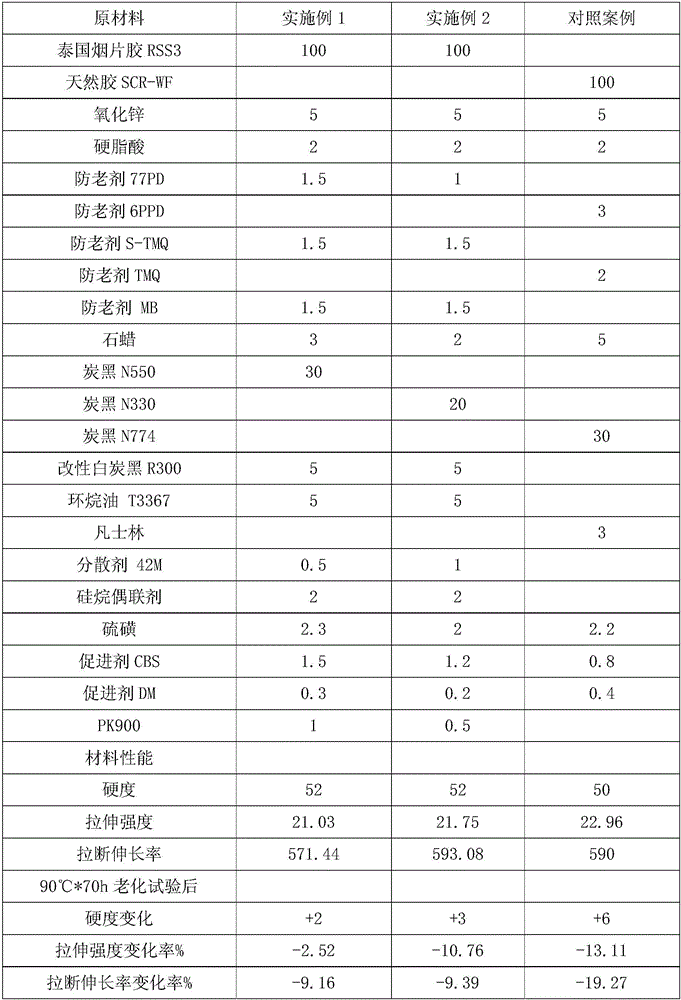

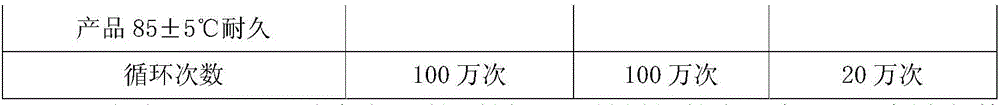

[0028] This embodiment relates to an engine mount rubber, the composition of which is shown in the table below, and the table also gives the composition of the control case for comparison with the engine mount rubber composition of this embodiment.

[0029]

[0030]

[0031] As can be seen from the above table, the engine mount compound prepared by the raw material ratio of the present invention has better dynamic fatigue durability and heat resistance, and the engine mount compound made of it can have better High temperature durability.

[0032] The preparation method of the engine mount rubber material in this embodiment adopts the two-stage rubber mixing process, and includes the following steps:

[0033] A section of rubber mixing, put the smoked sheet rubber into the internal mixer and knead for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com