Vegetable soilless culture nutrient solution

A technology of soilless cultivation and nutrient solution, applied in the direction of soilless cultivation, cultivation, culture medium, etc., can solve the problems of high production cost, environmental pollution, etc., and achieve the effects of stable physical properties, prevention and control of physiological diseases, and strong vegetable plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

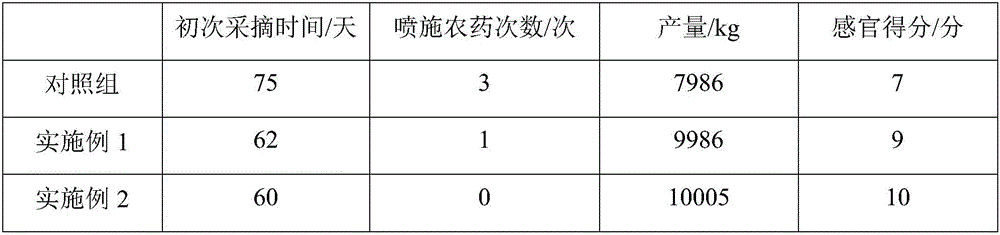

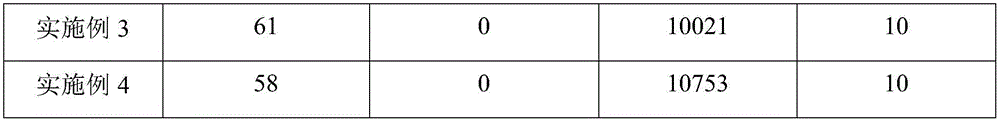

Examples

Embodiment 1

[0028] A nutrient solution for soilless cultivation of vegetables, which is mainly made of the following raw materials in parts by weight: 40 parts of edible fungus residue, 30 parts of silkworm excrement, 20 parts of chicken embryo egg powder, 20 parts of vermicompost, and 15 parts of Moringa oleifera leaf powder , 10 parts of duckweed grass powder, 10 parts of vinegar residue, 10 parts of konjac powder, 8 parts of rice bran, 8 parts of camphor leaf, 8 parts of heather flower, 8 parts of fumed white carbon black, 6 parts of β-cyclodextrin, 4 parts of mint , 4 parts of desmodium, 3 parts of nano-zinc oxide, 2 parts of oleander leaves, 0.5 parts of enzyme bacteria and 0.1 part of cellulase.

[0029] The nutrient solution for soilless cultivation of vegetables is mainly made by the following steps:

[0030] Step 1, each raw material is weighed by above-mentioned parts by weight:

[0031] Step 2. Mix rice bran, duckweed grass powder, Moringa leaf powder and vinegar residue evenl...

Embodiment 2

[0040] A nutrient solution for soilless cultivation of vegetables, which is mainly made of the following raw materials in parts by weight: 43 parts of edible fungus residue, 33 parts of silkworm excrement, 23 parts of chicken embryo egg powder, 23 parts of vermicompost, and 18 parts of Moringa oleifera leaf powder , 13 parts of duckweed grass powder, 13 parts of vinegar residue, 13 parts of konjac powder, 9 parts of rice bran, 9 parts of camphor leaf, 9 parts of heather flower, 9 parts of fumed white carbon black, 7 parts of β-cyclodextrin, 5 parts of mint , 5 parts of desmodium, 4 parts of nano-zinc oxide, 2.5 parts of oleander leaves, 0.8 parts of enzyme bacteria and 0.2 parts of cellulase.

[0041] The nutrient solution for soilless cultivation of vegetables is mainly made by the following steps:

[0042] Step 1, each raw material is weighed by above-mentioned parts by weight:

[0043] Step 2. Mix rice bran, duckweed grass powder, Moringa leaf powder and vinegar residue ev...

Embodiment 3

[0052] A nutrient solution for soilless cultivation of vegetables, which is mainly made of the following raw materials in parts by weight: 45 parts of edible fungus residue, 35 parts of silkworm excrement, 25 parts of chicken embryo egg powder, 25 parts of vermicompost, and 20 parts of Moringa leaf powder , 15 parts of duckweed grass powder, 15 parts of vinegar residue, 15 parts of konjac powder, 10 parts of rice bran, 10 parts of camphor leaf, 10 parts of heather flower, 10 parts of fumed white carbon black, 8 parts of β-cyclodextrin, 6 parts of mint , 6 parts of desmodium, 5 parts of nano-zinc oxide, 3 parts of oleander leaves, 1 part of enzyme bacteria and 0.3 parts of cellulase.

[0053] The nutrient solution for soilless cultivation of vegetables is mainly made by the following steps:

[0054] Step 1, each raw material is weighed by above-mentioned parts by weight:

[0055] Step 2. Mix rice bran, duckweed grass powder, Moringa leaf powder and vinegar residue evenly, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com