Rhizoma Belamcandae decoction pieces rich in flavonoid aglycones and preparation technology of Rhizoma Belamcandae extract

A technology for extracting and flavonoid aglycone of Shegan, which is applied in the field of preparing high-efficiency decoction pieces of Shegan rich in flavonoid aglycone and its extract, can solve the problems of not separating flavonoid aglycone, and achieve the effects of simple method and low impurity content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

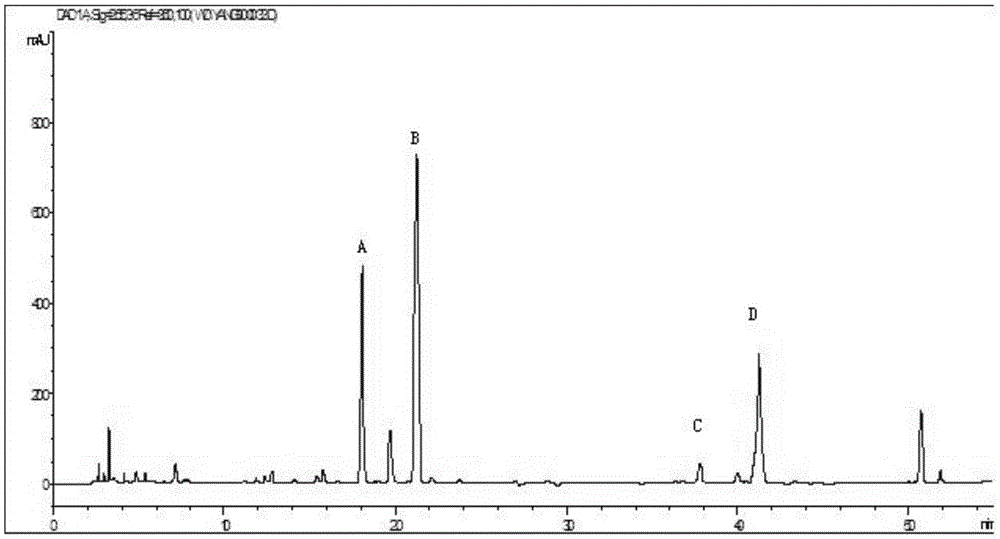

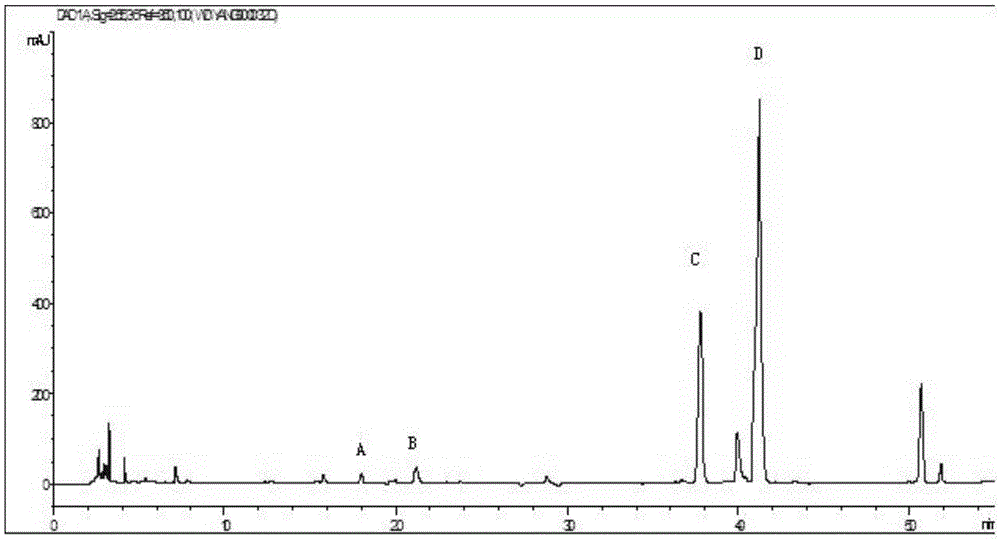

[0023] Optimization of enzymatic conversion process of total aglycon in Shegan

[0024] Instruments: Agilent 1100 liquid chromatography system (Agilent Corporation, USA), Phenomenex chromatographic column (Phenomenex Synergi 4u polar-RP 80A 250×4.6mm 4micron), PHS-25CPH meter (Shanghai Tangyi Instrument Co., Ltd.), KQ-250DB numerical control ultrasonic Cleaner (Kunshan Ultrasonic Instrument Co., Ltd.), DZF-6050 vacuum drying oven (Gongyi Yuhua Instrument Co., Ltd.).

[0025] Test drugs: Shegan Decoction Pieces (Anhui Huqiao Traditional Chinese Medicine Decoction Pieces Factory, batch number: 20141120); citric acid (Sinopharm Chemical Reagent Co., Ltd., batch number: 20140415), sodium citrate (Shenyang Reagent No. 1 Factory, batch number: 880703); β-glucose Glucosidase (Hubei Dahua Weiye Pharmaceutical Chemical Co., Ltd., batch number: 20150103 potency: 100,000 U / mg).

[0026] Taking the content of total glycosides and total aglycones in Shegan as the investigation index, the ...

Embodiment 2

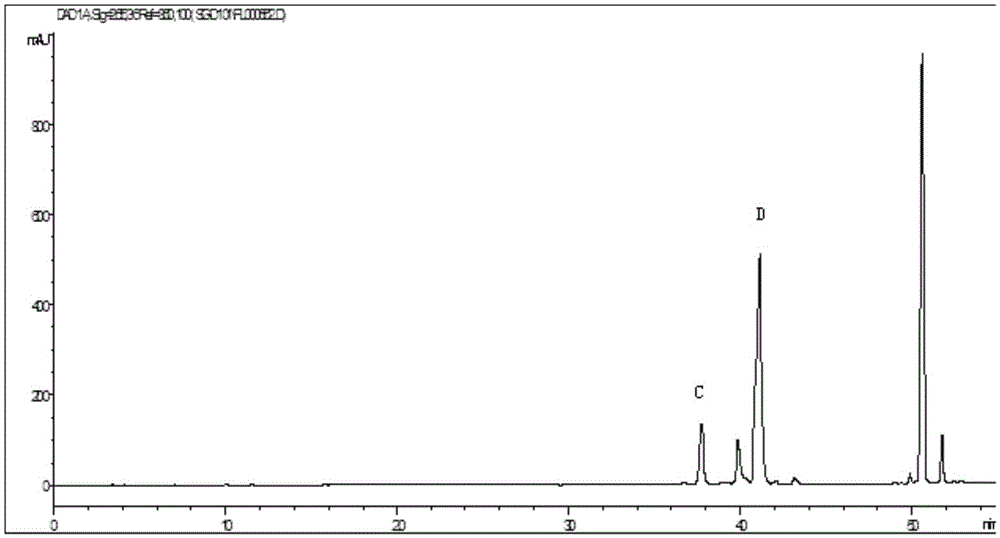

[0030] The technical method of enriching and purifying total aglycones with commercialized D101 macroporous adsorption resin, the steps are as follows:

[0031] (1) At 45°C, add 40 million U of β-glucosidase to 1Kg Shegan decoction pieces, soak in citric acid-sodium citrate buffer solution with pH=4.5 for 48 hours, take it out, and drain the water , dried, crushed, and then refluxed with 8 times and 6 times the volume of 70% ethanol to extract twice, each time for 2 hours, the combined filtrate was distilled under reduced pressure to recover ethanol, and the alcohol concentration was adjusted to 30%, standing for 12 hours, centrifuged to remove a small amount of insoluble material to obtain 2000ml of adsorption solution containing 0.5g of crude drug per 1ml.

[0032] (2) Pass 2BV of the above-mentioned adsorption solution through a resin column equipped with D101 macroporous adsorption resin (column inner diameter 10cm, column length 150cm, 6000mL wet resin is housed), and the...

Embodiment 3

[0038]The difference from Example 2 is that in step (1), the amount of β-glucosidase added is 50 million U, soaked in citric acid-disodium hydrogen phosphate buffer solution with pH=5 for 24 hours. Finally, 31.60 g of total aglycone extract was obtained, and determined by HPLC analysis, the total aglycon content in the extract was 15.5% (w%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com