A process and system for electric field synergistic stabilization treatment of multivalent arsenic-containing waste residue

A stabilization treatment, multi-valence technology, applied in the direction of protection devices against harmful chemicals, etc., can solve the problems of arsenic secondary pollution and thermal pollution that are difficult to control, high operating costs and energy consumption, landfill and storage burdens, etc. , to achieve the effect of low cost, reduced dissolution rate and small capacity increase ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

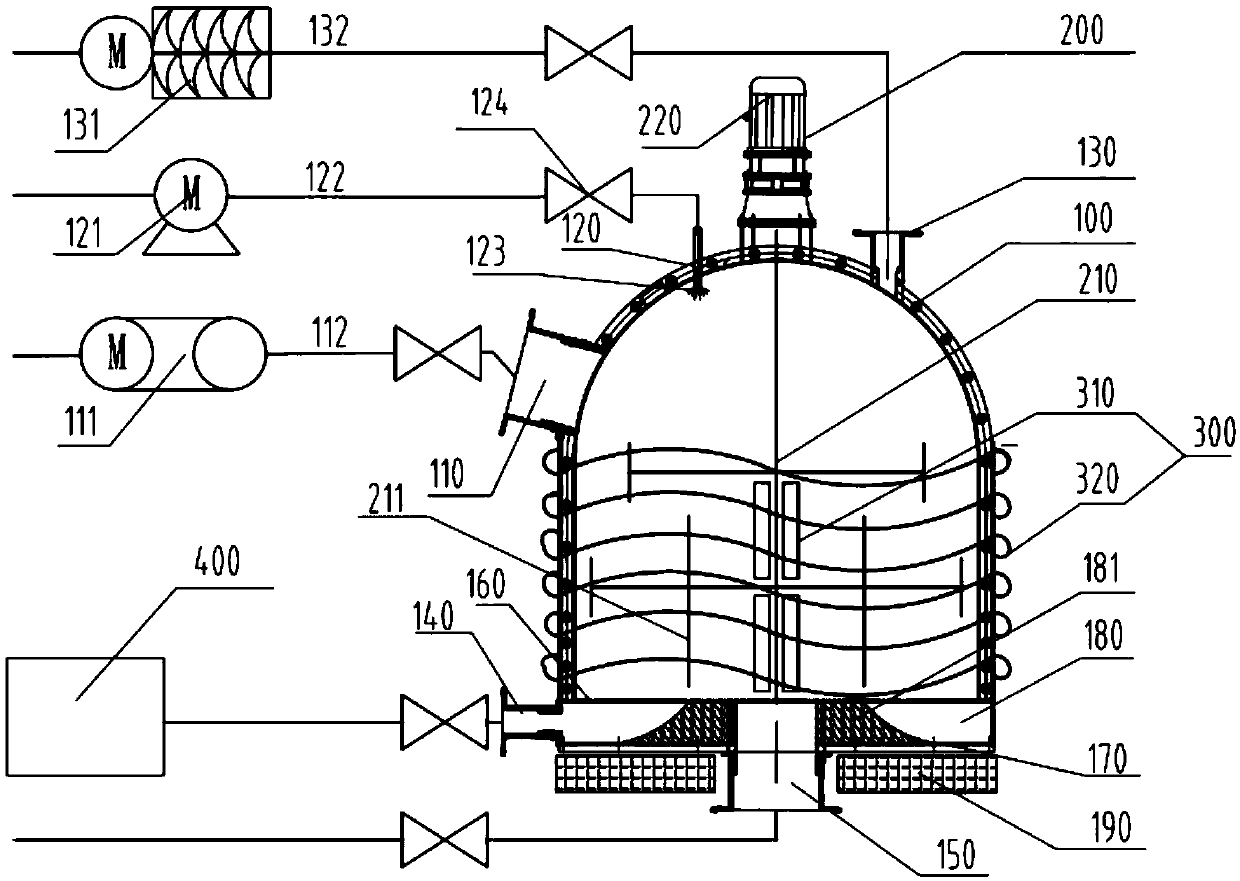

[0031] combine figure 1 , a system for electric field synergistic stabilization treatment of polyvalent arsenic-containing waste slag provided by the present invention is described:

[0032] A system for electric field synergistic stabilization treatment of multivalent arsenic-containing waste residue, comprising: a reaction tank body 100, which is provided with a waste residue feed port 110, an oxidant feed port 120, a stabilizer feed port 130, an infiltration tank body 100, Filtrate outlet 140 and waste outlet 150. The waste slag feed port 110 is connected with the first pipeline 112 with the belt conveyor 111; the oxidant feed port 120 is connected with the second pipeline 122 with the metering pump 121, and the oxidant discharge port 120 is also provided with a nozzle 123, and the nozzle 123 is placed Inside the reaction tank body 100 ; the stabilizer feeding port 130 is connected to the third pipeline 132 with a screw conveyor 131 . The first pipeline 112, the second pi...

Embodiment 2

[0039] The present invention also provides a process for treating polyvalent arsenic-containing waste slag through electric field synergistic stabilization, comprising the following steps:

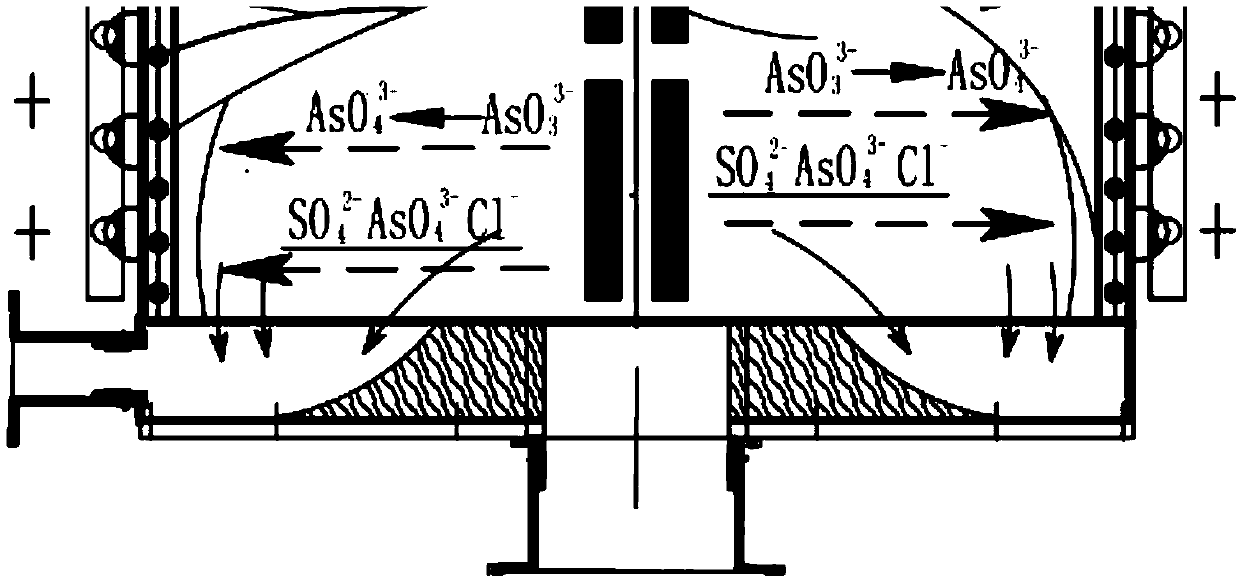

[0040] Step 1: Add an oxidizing agent to the arsenic-containing waste residue with a water content of 50%-70% and stir to oxidize the arsenic; while adding the oxidant, apply an electric field to the arsenic-containing waste residue, the cathode of the electric field is located in the middle of the arsenic-containing waste residue, and the anode It is located around the arsenic-containing waste slag so that the anions in the arsenic-containing waste slag migrate to the anode. Wherein, the ratio of the added volume of the oxidizing agent to the volume of arsenic in the arsenic-containing waste residue is less than or equal to 1:10, the oxidizing agent includes one or more of potassium permanganate solution and hydrogen peroxide solution, and the mass fraction of the oxidizing agent is 10%-30...

Embodiment 3

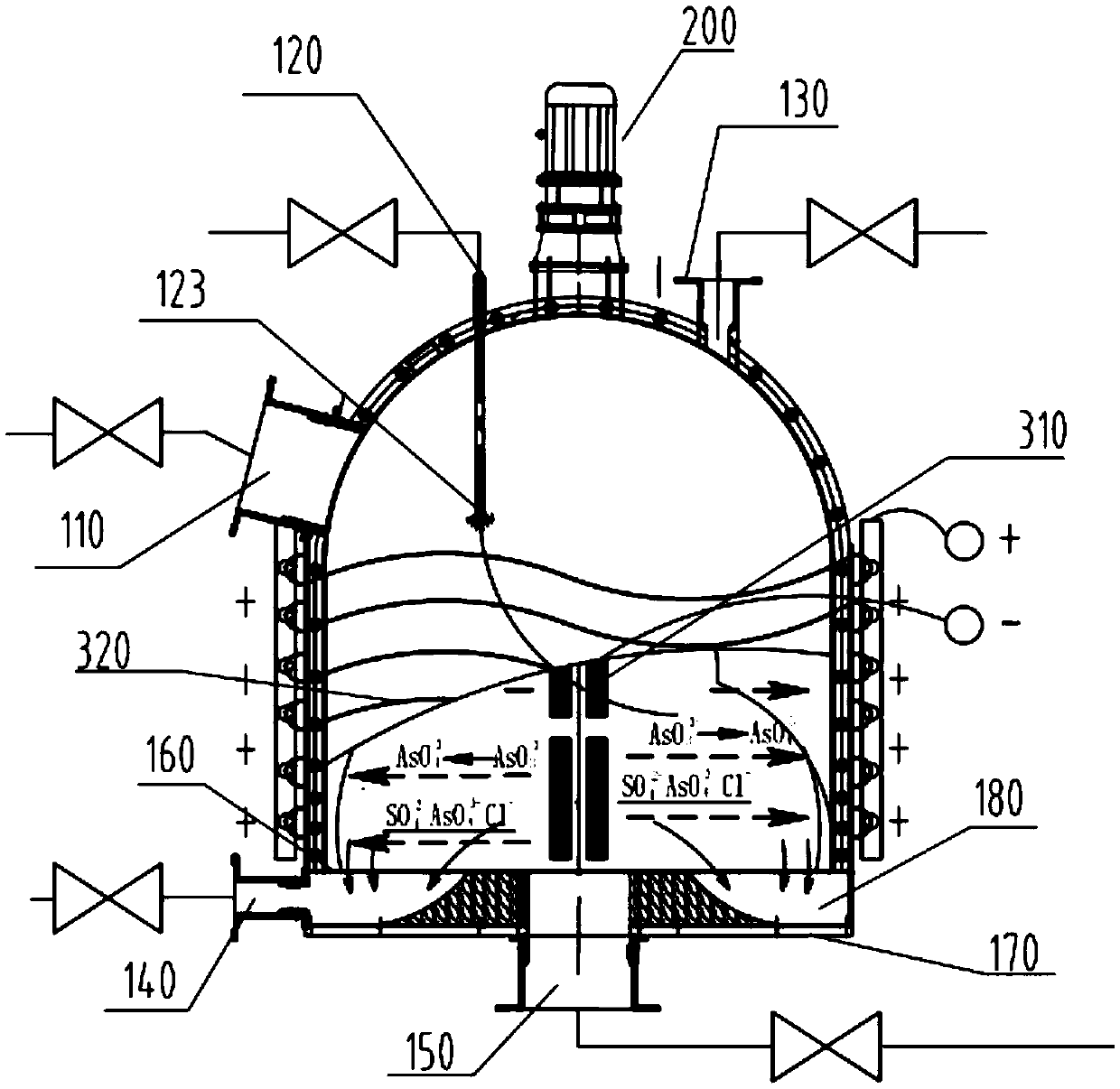

[0049] refer to figure 2 , Figure 4 , and combined with the system for treating arsenic-containing waste slag provided by the present invention, the process of electric field synergistic stabilization for treating polyvalent arsenic-containing waste slag is described in detail.

[0050] Step 1: The arsenic-containing waste residue is transported to the waste residue feed port 110 by the belt conveyor 111 and enters the reaction tank 100 . Wherein, the belt conveyor 111 is connected with the electronic weighing scale 190, and the electronic measuring pump 190 measures the increased weight of the reaction tank body 100. When the increased weight of the reaction tank body 100 reaches a predetermined setting value, the electronic weighing scale 190 feeds back an electronic signal to close the belt. The conveyor 111 stops the conveyance of the arsenic-containing waste slag, so that the purpose of measuring the arsenic-containing waste slag is achieved.

[0051] Step 2: Start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com