a waste water processor

A processor and wastewater technology, applied in water/sewage treatment, water/sludge/sewage treatment, standpipe evaporator, etc., can solve problems such as affecting the efficiency of evaporation, and achieve extended service life, simple equipment and low investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific situation of the present invention is further illustrated below through specific examples, but not limited to the following examples.

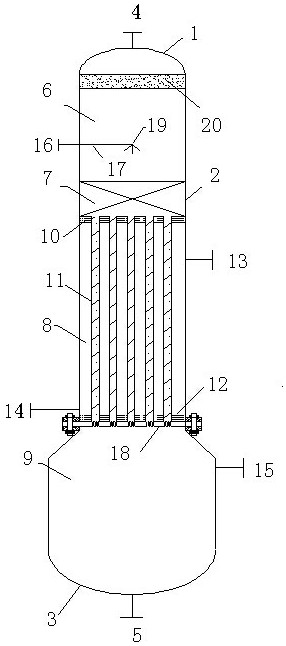

[0024] Such as figure 1 As shown, the present invention provides a kind of waste water processor, and described processor comprises upper sealing head 1, housing 2, lower sealing head 3, and described upper sealing head 1 is provided with gas outlet 4, and described lower sealing head 3 is provided with There is a concentrated liquid outlet 5, and the shell 2 includes a vapor-liquid separation section 6, a material distribution section 7, an evaporation section 8, and a liquid storage section 9 according to the flow direction of the liquid phase material; the gas-liquid separation section 6 is equipped with a fiber demister 20, the housing above the material distribution section 7 is provided with a feed port 16, the feed port is connected with a feed pipe 17, and the feed pipe 17 is connected with a feed distributor 19, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com