Method for preparing niobium monoxide and niobium powder mixture through plasma decomposition

A niobium monoxide and mixture technology, which is applied in the field of ion decomposition to prepare a mixture of niobium monoxide and niobium powder, can solve the problems of high price, complicated extraction process, and low efficiency, and achieve the goal of reducing production cost, improving preparation efficiency, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

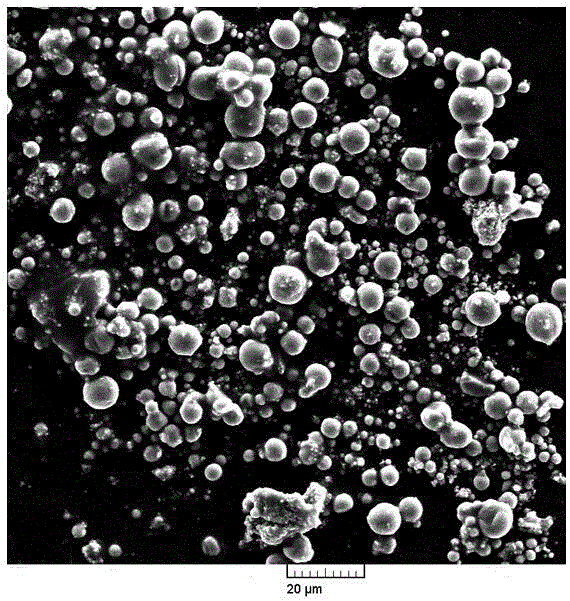

Image

Examples

Embodiment 1

[0023] In the embodiment of the present invention, a method for preparing a mixture of niobium monoxide and niobium powder by plasma decomposition, using niobium pentoxide as a raw material, performing plasma pyrolysis on it to prepare a mixture of niobium monoxide and niobium powder, the specific preparation steps are: Inject niobium pentoxide into the plasma gun through a powder feeder, the powder feeding rate is 20g / min; the powder feeding gas is argon, and the flow rate is 0.65m 3 / h; the ion gas is argon, and the flow rate is 2.5m 3 / h; the mixture of niobium monoxide and niobium powder is obtained by decomposing at the same time the high temperature of the plasma flame changes the particle shape, and the decomposition power is 14.37kW; through the action of gravity, the mixture of niobium monoxide and niobium powder obtained by decomposition falls into a pure water circulation The cooling device of the system, at the same time, inject argon gas into the cooling device to...

Embodiment 2

[0026] In the embodiment of the present invention, a method for preparing a mixture of niobium monoxide and niobium powder by plasma decomposition, using niobium pentoxide as a raw material, performing plasma pyrolysis on it to prepare a mixture of niobium monoxide and niobium powder, the specific preparation steps are: Inject niobium pentoxide into the plasma gun through the powder feeder, the powder feeding volume is 15g / min; the powder feeding gas is argon, and the flow rate is 0.75m 3 / h; the ion gas is argon, and the flow rate is 2.2 m 3 / h; the mixture of niobium monoxide and niobium powder is obtained by decomposing at the same time the high temperature of the plasma flame changes the particle shape, and the decomposition power is 20kW; through the action of gravity, the mixture of niobium monoxide and niobium powder obtained by decomposition falls into the pure water circulation system At the same time, argon gas is injected into the cooling device to protect the produ...

Embodiment 3

[0029] In the embodiment of the present invention, a method for preparing a mixture of niobium monoxide and niobium powder by plasma decomposition, using niobium pentoxide as a raw material, performing plasma pyrolysis on it to prepare a mixture of niobium monoxide and niobium powder, the specific preparation steps are: Feed niobium pentoxide into the plasma gun through a powder feeder, the powder feeding volume is 22g / min; the powder feeding gas is argon, and the flow rate is 0.7m 3 / h; the ion gas is argon, the flow rate is 2.4m 3 / h, through the high temperature of the plasma flame to change the particle shape and decompose at the same time to obtain a mixture of niobium monoxide and niobium powder, the decomposition power is 15kW; through the action of gravity, the mixture of niobium monoxide and niobium powder obtained by decomposition falls into a pure water circulation system At the same time, argon gas is injected into the cooling device to protect the product from oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com