Humic acid composite fertilizer and preparation method thereof

A technology of humic acid and compound fertilizer, applied in urea compound fertilizer, ammonium orthophosphate fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problems of easy nutrient loss, soil compaction, short fertilizer efficiency, etc., and improve soil permeability properties, increase soil fertility, and improve the effect of fertilizer utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

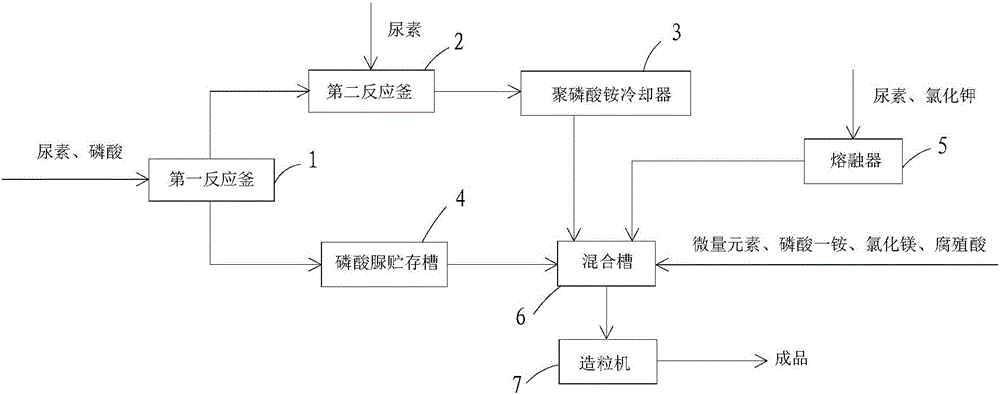

[0045] See figure 1 The present invention also provides a preparation method of the above-mentioned humic acid compound fertilizer, including the following steps:

[0046] S1 prepares raw materials of humic acid, phosphoric acid, urea, magnesium oxide, monoammonium phosphate, potassium chloride and trace elements. Since urea phosphate is synthesized from urea and phosphoric acid, ammonium polyphosphate is made from said urea and urea. Synthesis, the final preparation also contains urea raw materials, so urea needs to be prepared according to urea phosphate synthesis, ammonium polyphosphate synthesis and humic acid compound fertilizer preparation respectively according to the first urea, the second urea, and the third urea;

[0047] S2 prepares urea phosphate:

[0048] 75%-85% phosphoric acid is sprayed into the first reactor 1 which has been filled with the first portion of urea. The first reactor 1 is equipped with a vacuum device and a stirring device, and the molar ratio of the ...

Embodiment 1

[0057] 1. Preparation of Urea Phosphate:

[0058] According to the molar ratio of urea to phosphoric acid of 1:1, 85% phosphoric acid was added to the first reactor pre-filled with the first part of urea and mixed and stirred, maintaining normal pressure, the speed of the stirring device was 300r / min, and the reaction temperature was 85°C. The reaction time is 30min. After the reaction is completed, the urea phosphate solution is stored in the urea phosphate storage tank.

[0059] 2. Preparation of ammonium polyphosphate:

[0060] According to the molar ratio of urea and urea phosphate of 1:2, the second portion of urea and urea phosphate solution was put into the second reaction kettle, and reacted for 90 minutes at a temperature of 220° C., and the prepared ammonium polyphosphate had a polymerization degree of 8. After the reaction was completed, the ammonium polyphosphate was put into the ammonium polyphosphate cooling tower and cooled to 110°C.

[0061] 3. Preparation of compoun...

Embodiment 2

[0065] 1. Preparation of Urea Phosphate:

[0066] According to the molar ratio of urea to phosphoric acid of 1:0.95, 75% phosphoric acid was added to the first reactor containing the first portion of urea, the vacuum in the reactor was controlled to 0.5Mpa, the speed of the stirring device was 250r / min, and the reaction temperature 90°C, reaction time 35min.

[0067] 2. Preparation of ammonium polyphosphate:

[0068] According to the molar ratio of urea to urea phosphate of 1:2.2, the second portion of urea and urea phosphate solution was mixed in the second reaction kettle, and reacted at a temperature of 260° C. for 100 min. The prepared ammonium polyphosphate had a polymerization degree of 8. After the reaction was completed, the ammonium polyphosphate was put into the ammonium polyphosphate cooling tower and cooled to 100°C.

[0069] 3. Preparation of compound fertilizer:

[0070] Melt the third portion of urea 25kg, add 30kg potassium chloride, transfer to the mixing tank, contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com