The preparation method of polyvinylidene fluoride

A technology of polyvinylidene fluoride and vinylidene fluoride, which is applied in the field of preparation of polyvinylidene fluoride, can solve the problems of product yellowing, chemical resistance reduction, and processing difficulties, and achieve mild process conditions, high production efficiency, and uniform molecular weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

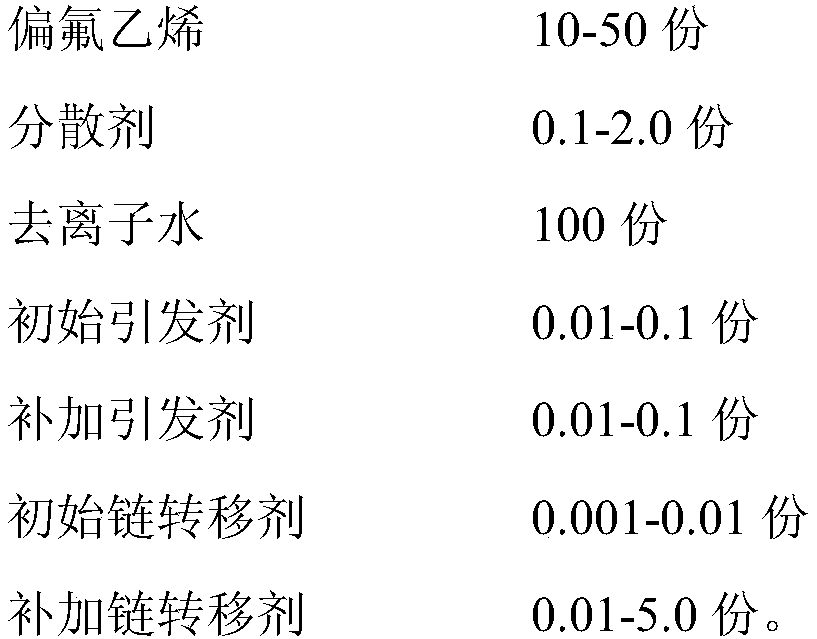

Method used

Image

Examples

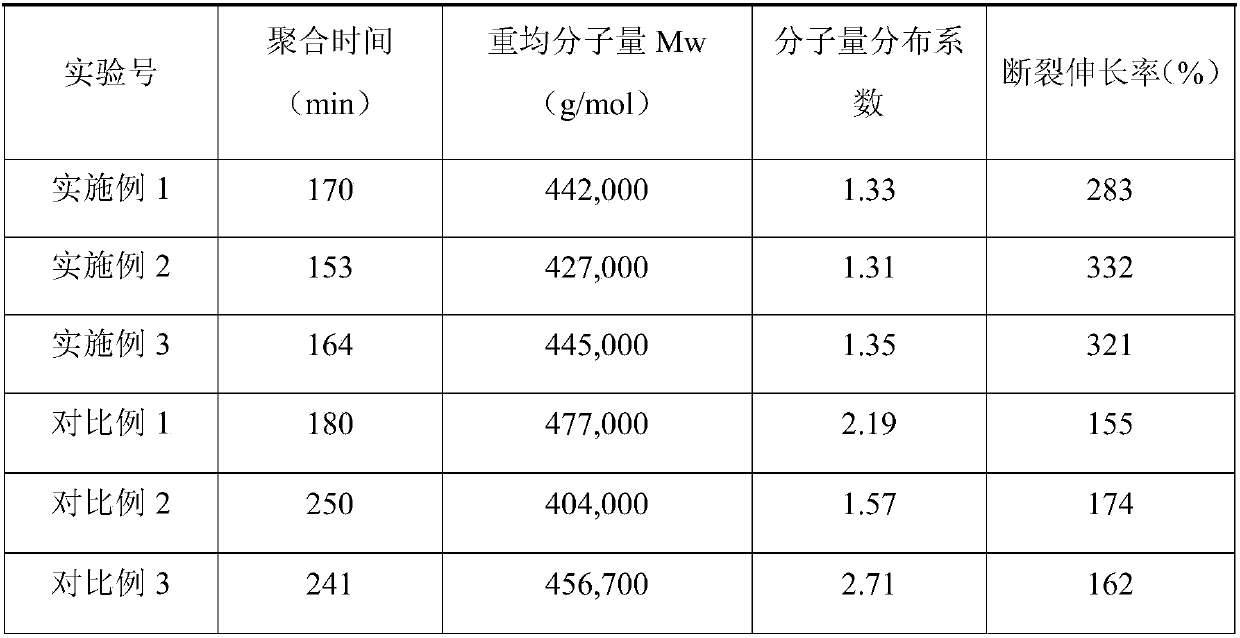

Embodiment 1

[0033] In a 100L horizontal reactor, add 60L of deionized water, 2g of initial chain transfer agent ethyl acrylate, and 100g of an aqueous solution of 20% perfluorocarboxylate polyether ammonium salt, evacuate and remove oxygen until the oxygen content is ≤30ppm is qualified. Then the temperature of the polymerization kettle is raised to 60° C., by adding vinylidene fluoride monomer to the pressure of 3.0 MPa in the kettle, then use a metering pump to quickly inject 100 g of the initial organic initiator solution (15% diisopropyl Hydrogen peroxide), start polymerization, keep temperature, pressure constant, after 10min, inject at a constant speed with metering pump, 1500g10% chain transfer agent solution (regulator is ethyl propionate) and 300g 15% add trigger Dosage solution, 2h finished. During the polymerization reaction, keep the temperature and pressure of the kettle constant, and stop the reaction when a certain amount of reaction is reached. Coagulation, washing, dryi...

Embodiment 2

[0035] The difference from Example 1 is that the initial chain transfer dose is changed to 5 g, and the additional chain transfer dose is changed to 3000 g of 5% chain transfer agent solution.

Embodiment 3

[0037] The difference from Example 1 is that the added chain transfer agent is changed to ethyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com