High-temperature-tolerance far-infrared coating as well as preparation method and application thereof

A far-infrared, high-temperature-resistant technology, used in coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc., can solve problems such as poor heat resistance, detachment of heating equipment, etc., to achieve stable state, simple composition, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]The high-temperature-resistant far-infrared coating of the present embodiment is made up of the composition of following parts by weight: 33 parts of sodium silicate glass, 33.2 parts of chromium oxide green powder, 6 parts of the mixture of tourmaline powder and medical stone powder (tourmaline powder 4 2 parts, medical stone powder), 1.3 parts of silane coupling agent, 3.2 parts of glycerin, 22 parts of water. Wherein, the mass concentration of sodium silicate is 35%, and the particle diameters of chromium oxide green powder, tourmaline powder and medical stone powder are all 0.1-0.5 μm.

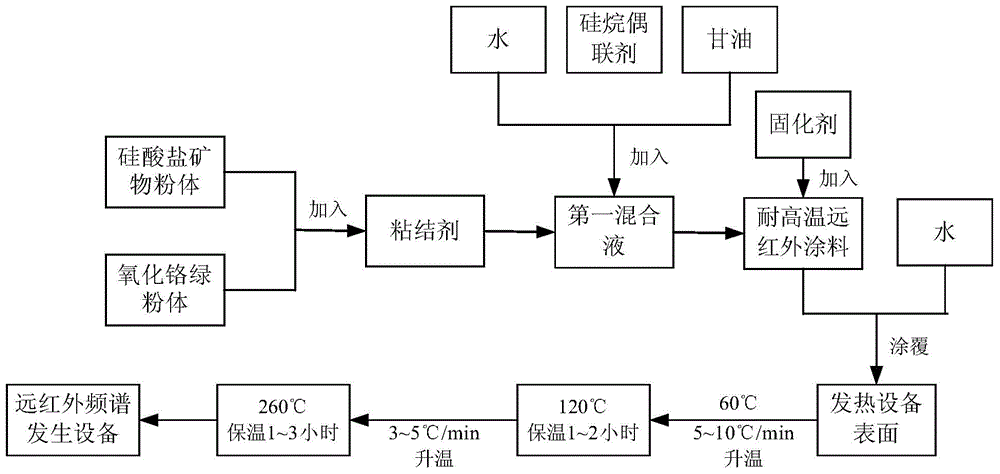

[0032] figure 1 It is a flow chart of the preparation and application of the high-temperature-resistant far-infrared coating of the present invention. Please refer to figure 1 , after according to above-mentioned composition batching, this high temperature resistant far-infrared coating can be prepared as follows:

[0033] 1) Add the mixture of tourmaline powder and medical stone ...

Embodiment 2

[0041] The high-temperature-resistant far-infrared coating of the present embodiment is made up of the following components by weight: 30 parts of mixtures of sodium silicate and silica sol, 34.5 parts of chromium oxide green powder, tourmaline powder, Sibin pumice powder and medical stone powder 10 parts of the mixture (4 parts of tourmaline powder, 4 parts of Sibin pumice powder, 2 parts of medical stone powder), 0.5 parts of silane coupling agent, 4 parts of glycerin, 20 parts of water, 1 part of aluminum dihydrogen phosphate. Among them, the mass concentration of sodium silicate is 40%, the mass concentration of silica sol is 35%, and the particle diameters of chromium oxide green powder, tourmaline powder, Sibin pumice powder and medical stone powder are all 1.5-2 μm.

[0042] After according to above-mentioned composition batching, this high temperature resistant far-infrared coating can be prepared as follows:

[0043] 1) Add the mixture of tourmaline powder, Sibin pumi...

Embodiment 3

[0051] The high-temperature resistant far-infrared coating of the present embodiment is made up of the composition of following parts by weight: 35 parts of lithium water glass, 35 parts of chromium oxide green powder, 7 parts of the mixture of seagull powder and diatomite powder (seagull powder body 4 parts, diatomite powder 3 parts), silane coupling agent 1 part, glycerin 3.5 parts, water 15 parts. Wherein, the mass concentration of lithium water glass is 30%, and the particle diameters of chromium oxide green powder, seagull stone powder and diatomite powder are all 1.5-2 μm.

[0052] After according to above-mentioned composition batching, this high temperature resistant far-infrared coating can be prepared as follows:

[0053] 1) Add the mixture of seagull stone powder and diatomite powder and chromium oxide green powder into lithium water glass, control the stirring speed to 1000r / min, and stir for 5min to form the first mixed solution;

[0054] 2) Add water, silane cou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com