Ultraviolet resistant sealant and preparation method thereof

A sealant and UV-resistant technology, applied in the field of sealants, can solve problems such as insufficient UV-resistant performance, and achieve the effects of improving various properties, reducing production costs, and having good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

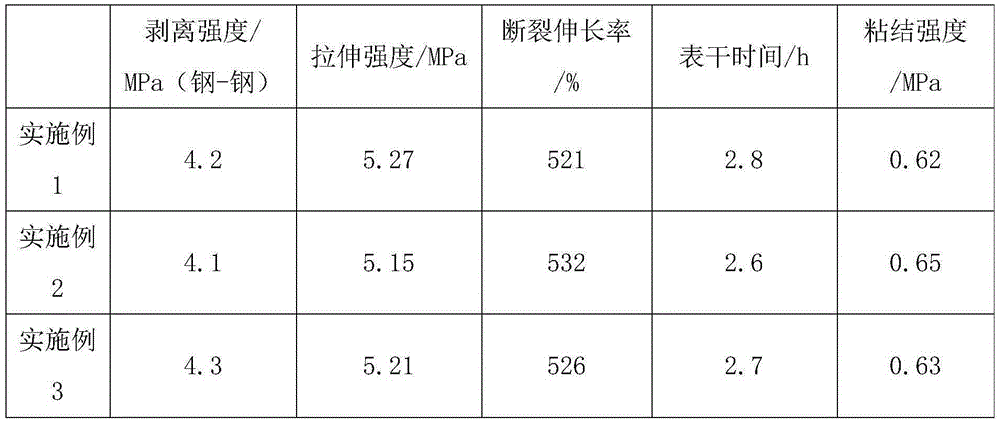

Examples

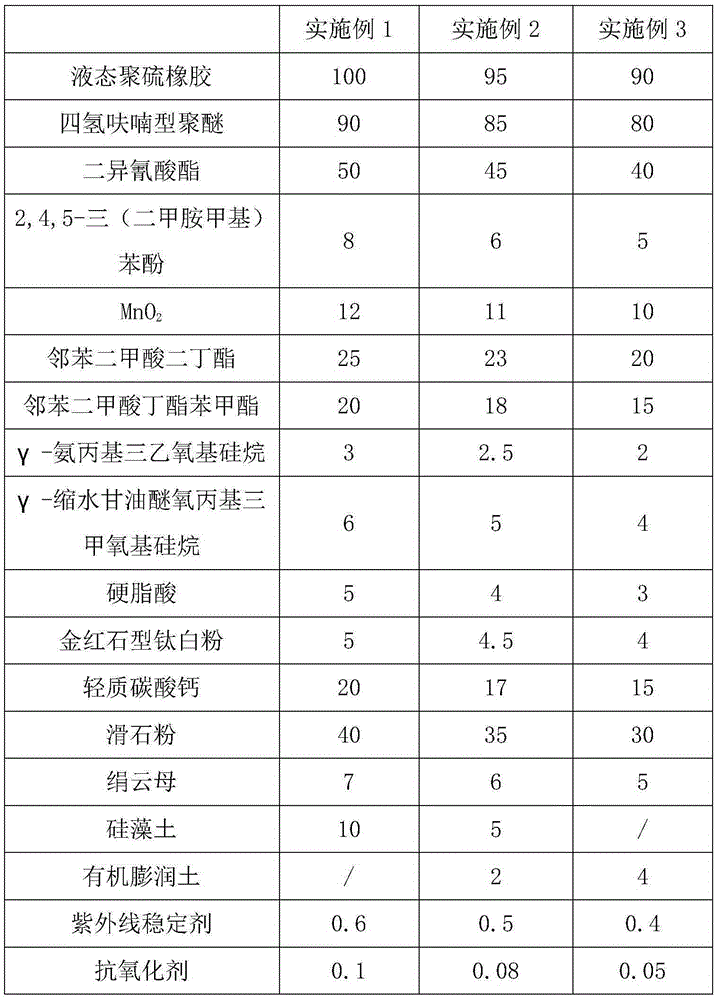

Embodiment 1

[0033] A UV-resistant sealant proposed in the embodiment of the present invention is prepared according to the following steps:

[0034] S1: Weigh each raw material according to the ratio of parts by weight;

[0035] S2: react tetrahydrofuran polyether with diisocyanate to obtain a prepolymer containing -NCO groups;

[0036] S3: Add γ-glycidyloxypropyltrimethoxysilane to γ-aminopropyltriethoxysilane under stirring, continue to stir after adding, react for 6 hours, and leave to obtain hydroxylamine group-containing Polyalkoxysilane, ready for use;

[0037]S4: liquid polysulfide rubber, 75% by weight of dibutyl phthalate, 75% by weight of butyl phthalate benzyl, stearic acid, 80% by weight of rutile titanium dioxide, The light calcium carbonate of 80% weight portion, the talcum powder of 80% weight portion, the sericite of 80% weight portion, the diatomite of 80% weight portion, ultraviolet stabilizer, antioxidant, the hydroxylamine group obtained in S3 Mix polyalkoxysilanes,...

Embodiment 2

[0040] A UV-resistant sealant proposed in the embodiment of the present invention is prepared according to the following steps:

[0041] S1: Weigh each raw material according to the ratio of parts by weight;

[0042] S2: react tetrahydrofuran polyether with diisocyanate to obtain a prepolymer containing -NCO groups;

[0043] S3: Add γ-glycidyloxypropyltrimethoxysilane to γ-aminopropyltriethoxysilane under stirring, continue to stir after adding, react for 6 hours, and leave to obtain hydroxylamine group-containing Polyalkoxysilane, ready for use;

[0044] S4: liquid polysulfide rubber, 75% by weight of dibutyl phthalate, 75% by weight of butyl phthalate benzyl, stearic acid, 80% by weight of rutile titanium dioxide, The light calcium carbonate of 80% weight portion, the talcum powder of 80% weight portion, the sericite of 80% weight portion, the diatomite of 80% weight portion, ultraviolet stabilizer, antioxidant, the hydroxylamine group obtained in S3 Mix polyalkoxysilanes...

Embodiment 3

[0047] A UV-resistant sealant proposed in the embodiment of the present invention is prepared according to the following steps:

[0048] S1: Weigh each raw material according to the ratio of parts by weight;

[0049] S2: react tetrahydrofuran polyether with diisocyanate to obtain a prepolymer containing -NCO groups;

[0050] S3: Add γ-glycidyloxypropyltrimethoxysilane to γ-aminopropyltriethoxysilane under stirring, continue to stir after adding, react for 6 hours, and leave to obtain hydroxylamine group-containing Polyalkoxysilane, ready for use;

[0051] S4: liquid polysulfide rubber, 75% by weight of dibutyl phthalate, 75% by weight of butyl phthalate benzyl, stearic acid, 80% by weight of rutile titanium dioxide, The light calcium carbonate of 80% weight portion, the talcum powder of 80% weight portion, the sericite of 80% weight portion, the diatomite of 80% weight portion, ultraviolet stabilizer, antioxidant, the hydroxylamine group obtained in S3 Mix polyalkoxysilanes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com