Algae cold soap and preparation method thereof

A technology for cold-making soap and seaweed, which is applied in chemical instruments and methods, soap detergents and other compounding agents, preparations for skin care, etc. The effect of no pollution in the process, scientific preparation method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

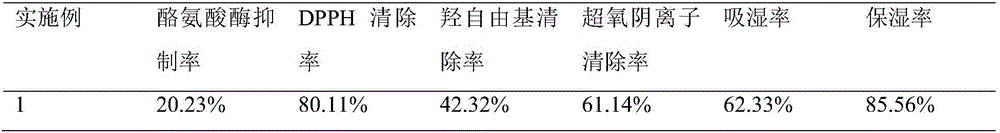

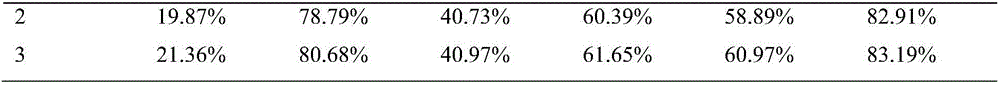

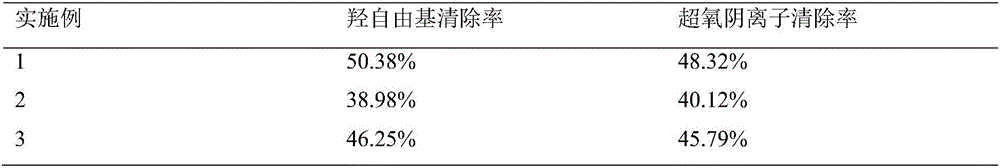

Examples

Embodiment 1

[0024] 1.1 composition and weight percent thereof of the present invention's cold-process soap containing seaweed extract and celery ethanol extract are:

[0025] Phase A: olive oil 12%, palm oil 18%, coconut oil 18%, sweet almond oil 12%, jojoba oil 1.5%, natural vitamin E oil 1.5%, seaweed oil 0.5%;

[0026] Phase B: 5% sodium hydroxide, 10% deionized water;

[0027] Phase C: 2% squalane, 0.5% nicotinamide, 1% sodium alginate, 8% seaweed extract, 2% alcohol extract of celery, 8% deionized water;

[0028] 1.2 Process:

[0029] The preparation method of the above-mentioned seaweed extract: wash the hijiki, dry, and pulverize the algae powder, mix 1 g of the algae powder with 100 mL of water, keep the temperature at 60° C., and extract under shaking conditions for 10 hours. Then, after taking it out, it was centrifuged at 4000 r / min for 15 minutes, and the hijiki extract was obtained after suction filtration.

[0030] The preparation method of the above-mentioned celery alco...

Embodiment 2

[0033] 2.1. composition and percentage by weight thereof of the cold process soap containing seaweed extract and celery ethanol extract of the present invention are:

[0034] Phase A: 30% olive oil, 18% evening primrose oil, 18% sweet almond oil;

[0035] Phase B: 4% sodium hydroxide, 10% deionized water;

[0036] Phase C: 1% squalane, 1% nicotinamide, 2% sodium alginate, 10% seaweed extract, 3% alcohol extract of celery, 3% deionized water;

[0037] 2.2. Process:

[0038] The preparation method of the seaweed extract is as follows: wash the algal algae, dry, and pulverize to obtain algal powder, mix 1 g of algae powder with 50 mL of water, keep the temperature at 20° C., and extract under shaking conditions for 24 hours. After taking it out, it was centrifuged at 4000r / min for 15min, and suction filtered to obtain the extract of S. edulis.

[0039] The preparation method of celery alcohol extract: fresh celery is washed, dried and pulverized, 1g of dry powder is added to 1...

Embodiment 3

[0042] 3.1. composition and percentage by weight thereof of the cold process soap containing seaweed extract and celery ethanol extract of the present invention are:

[0043] Phase A: Olive Oil 32%, Sweet Almond Oil 30%, Jojoba Oil 1%, Sesame Oil 1%, Natural Vitamin E Oil 1%, Avocado Oil 1%, Seaweed Oil 1%;

[0044] Phase B: 5.5% sodium hydroxide, 7.5% deionized water;

[0045] Phase C: 1% squalane, 1% nicotinamide, 1% sodium alginate, 4% seaweed extract, 10% alcohol extract of celery, 3% deionized water;

[0046] 3.2. Process:

[0047] The preparation method of the seaweed extract is as follows: wash the sea grapes, dry them, and pulverize them to obtain algal powder, mix 1 g of the algae powder with 10 mL of water evenly, keep the temperature at 30° C., and extract under shaking conditions for 24 hours. After taking it out, it was centrifuged at 4000r / min for 15min, and the sea grape extract was obtained after suction filtration.

[0048] The preparation method of the celer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com