Engineering bacterium capable of co-producing long-chain dicarboxylic acid and 1,3-propylene glycol and building method thereof

A technology of propanediol dehydrogenase and Clostridium butyricum, applied in the field of bioengineering, can solve the problems of simultaneous production without fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

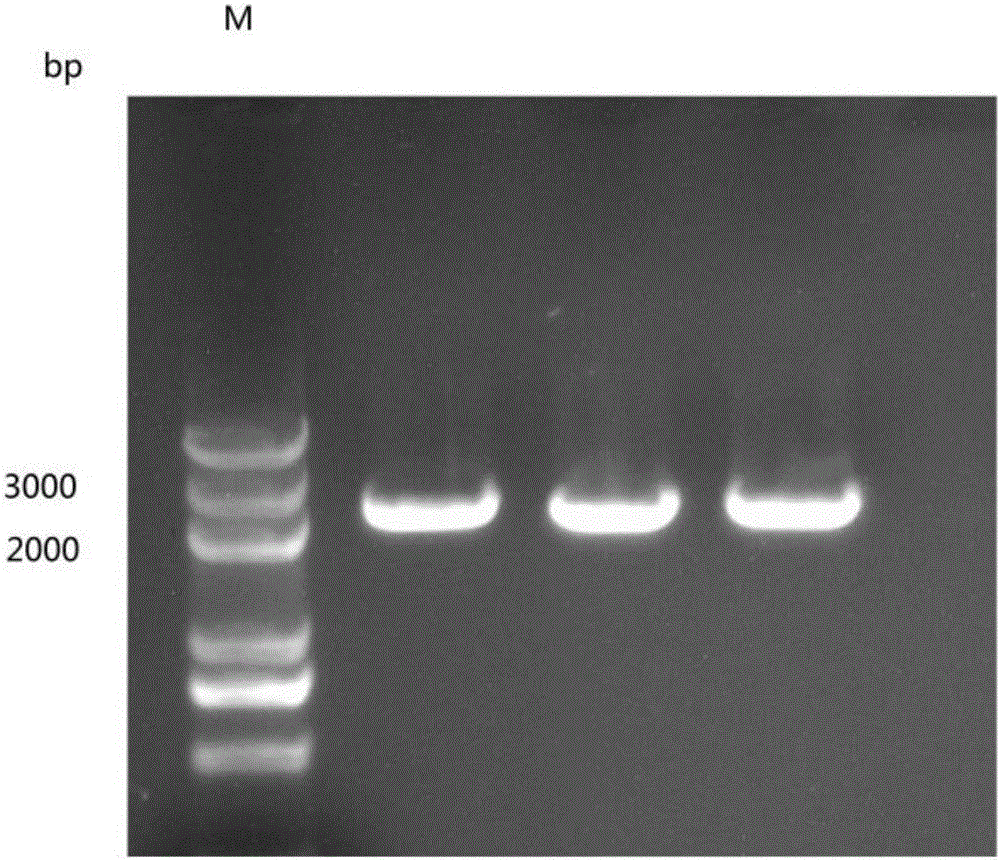

[0152] A method for preparing a recombinant plasmid, comprising the steps of:

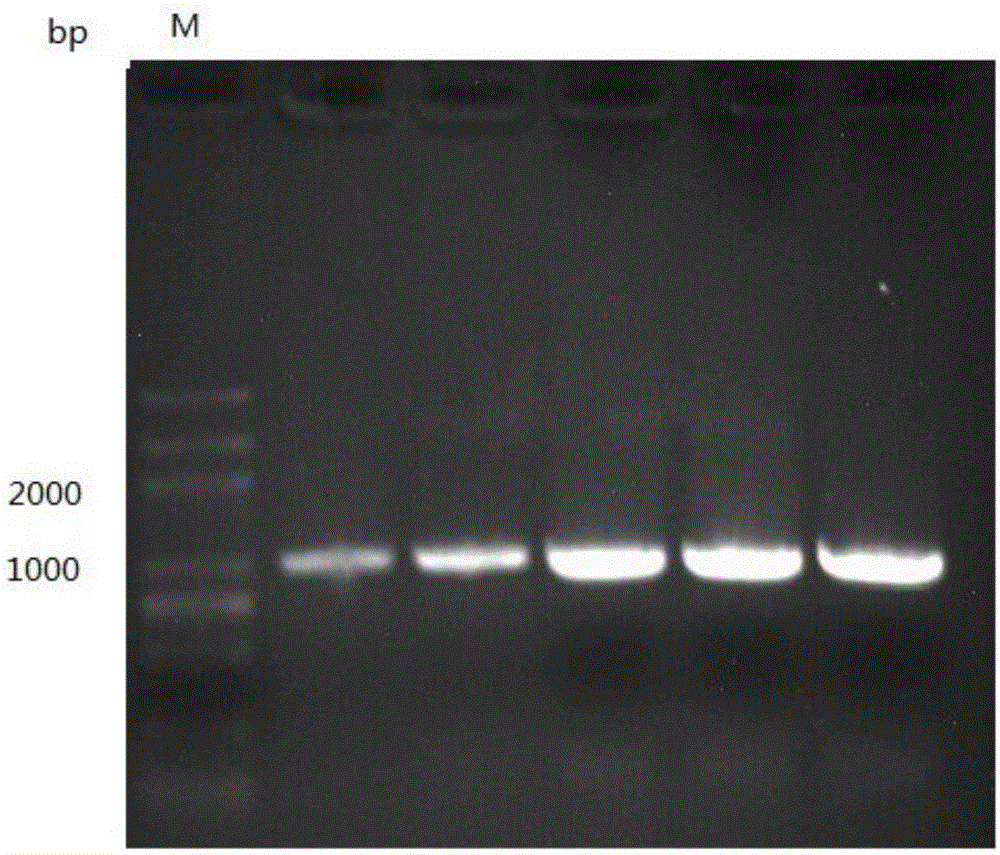

[0153] (1) Using the genome of Candida tropicalis as a template, carry out PCR amplification to obtain the promoter pGAPg fragment, and the electrophoresis results are as follows: figure 1 shown;

[0154] The primer nucleotide sequence of described PCR amplification is as follows:

[0155] pGAPg-up:5'- AGATCT AAGAAGAATTTAGTGGTTAGTCG-3',

[0156] pGAPg --down:5'-ATCCTTACTTATCATTGTTAAAATTTAATTTGTAAGTGATTTG-3';

[0157] The single underline is the enzyme cutting site Bgl II;

[0158] The amplification system of the PCR amplification is as follows, the total volume of the system is 50 μl:

[0159] 2×HiFi-PCR Master 25μl, 10μmol / L upstream primer 2μl, 10μmol / L downstream primer 2μl, template 2.5μl, use ddH 2 O supplemented to 50 μl;

[0160] The amplification procedure of described PCR amplification is as follows:

[0161] Pre-denaturation at 95°C for 5 min; denaturation at 95°C for 30 sec, ann...

Embodiment 2

[0282] A preparation method for transforming oil and co-producing long-chain dibasic acid and 1,3-propanediol Candida tropicalis engineering bacteria, comprising the following steps:

[0283] (i) preparing Candida tropicalis competent cells;

[0284] The preparation of described Candida tropicalis competent cell can adopt the conventional technique in this field, also can follow the steps as follows:

[0285] ① Inoculate Candida tropicalis on a YPD solid medium plate, culture at 30°C overnight, inoculate a single colony on the plate into 25ml of YPD liquid medium, and culture in a shaker at 30°C and 220rpm / min for 20 hours to obtain a seed solution ;

[0286] ② Take 0.5ml of the above seed solution and inoculate it into 25ml of YPD liquid medium, and culture it on a shaker at 220rpm / min at 30°C for 8h, so that the OD 600 Between 1.3 and 1.5, the expanded culture medium was prepared;

[0287] ③ Take 1ml of expanded culture medium into a 1.5ml EP tube, centrifuge at 3000rpm f...

Embodiment 3

[0297] Example 3 Construction and Fermentation Verification of Candida Tropicale Engineering Bacteria

[0298] The Candida tropicalis engineering bacterium constructed and obtained in Example 2 was inoculated in YPD medium, and the culture condition was 30° C. shaker for 12 hours, and then transferred to the Candida tropicalis fermentation medium at a ratio of 10% by volume, at 30 ℃ shaking table fermentation verification.

[0299] The YPD medium components are as follows:

[0300] Peptone 20g, glucose 20g, sodium chloride 10g, water to 1L.

[0301] The fermentation medium components are as follows:

[0302] Glucose 62g, ammonium sulfate 1g, yeast powder 2g, vitamin B1 0.2g, sodium chloride 2g, potassium dihydrogen phosphate 8g, disodium hydrogen phosphate 10g, urea 3g, magnesium sulfate 6g, water to 1L.

[0303] The yield of long-chain dibasic acid after fermentation by Candida tropicalis engineered bacteria was 10g / L, and the yield of 1,3-propanediol produced by convertin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com