Processing Technology of High Strength and High Elongation Brass Alloy Strip

A brass alloy and processing technology, which is applied in the processing technology field of high-strength and high-elongation brass alloy strips, can solve the problems that the requirements of the strength and elongation performance of brass cannot be met, and the requirements of brass performance are relatively strict, and the The effect of strengthening cooling intensity, improving comprehensive performance and good application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

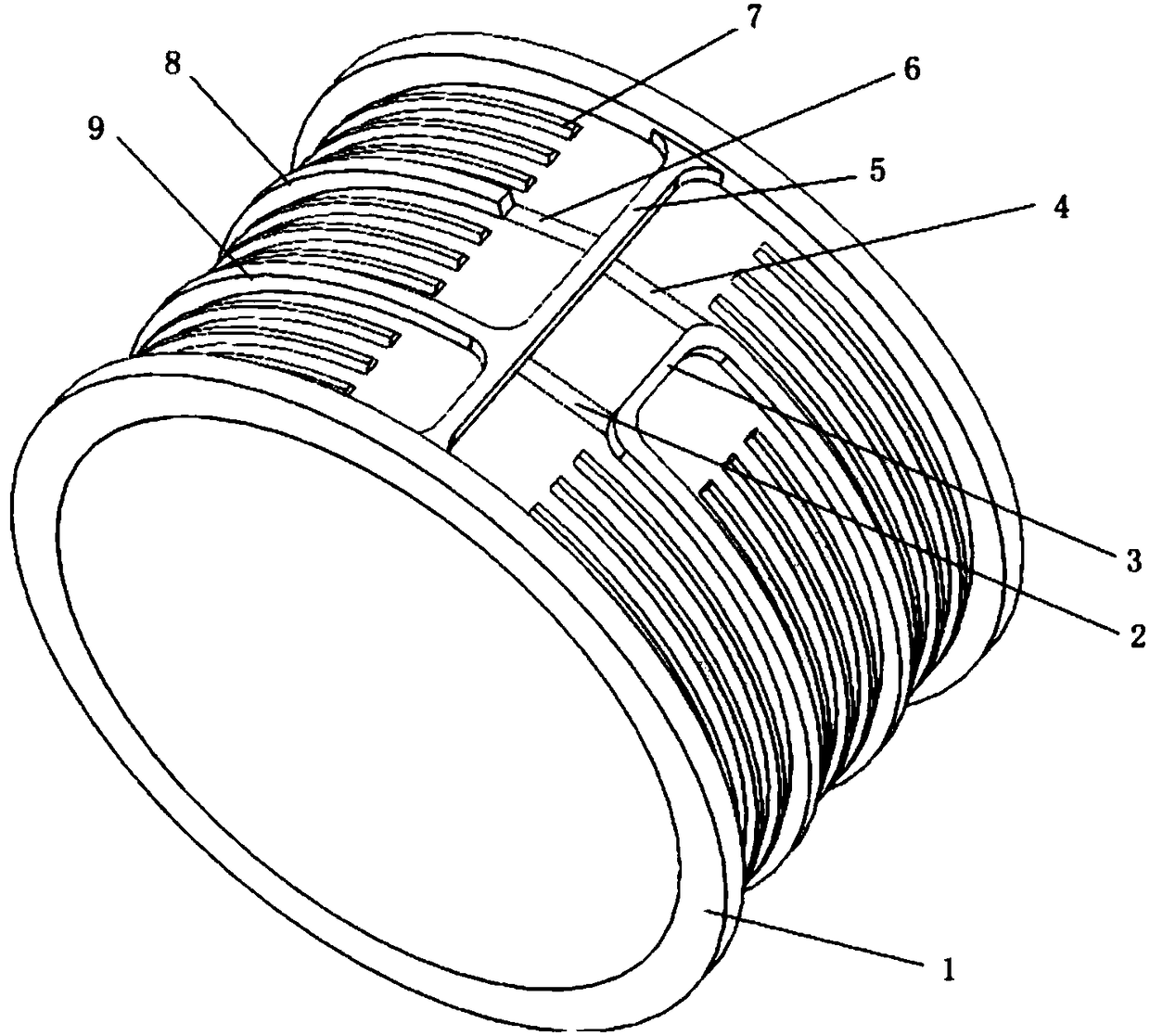

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

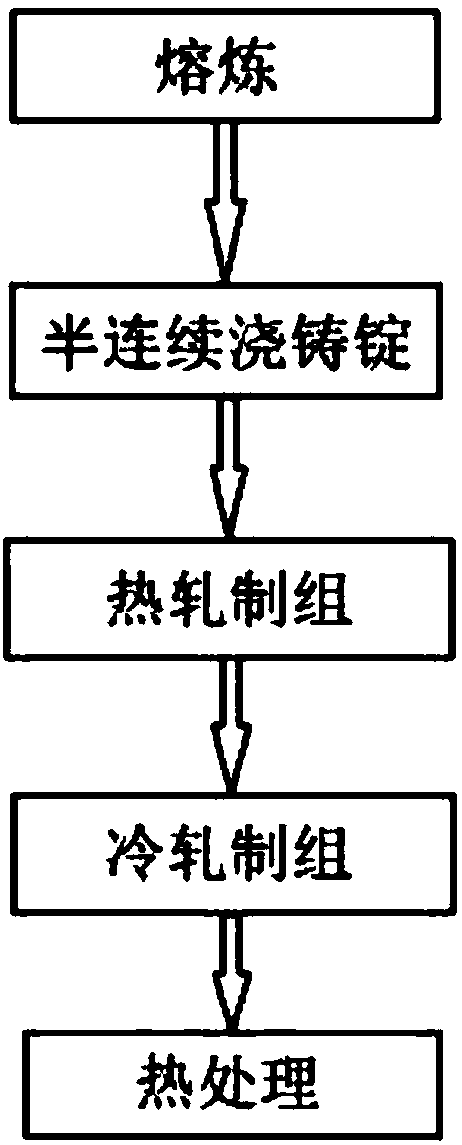

[0023] Such as figure 1 As shown, the processing technology adopted by the present invention to produce 0.1-0.2×400mm brass alloy strips is as follows: smelting half of the continuous casting ingot——cold rolling group—heat treatment.

[0024] (1) Choose copper and zinc as raw materials, and melt them in the smelting device after the raw materials are dried. The melting temperature is 850°C-1100°C. Rare earth lanthanide metals, manganese and iron are stirred, and baked charcoal is used as a covering agent to ensure the vacuum state of the alloy liquid. The thickness of the charcoal is 80mm-100mm. The mass percentages of the alloy components are: copper: 60%-80%, rare earth lanthanide metals: 0-0.3%, manganese: 0-0.4%, iron: 0-0.03%, unavoidable impurities less than or equal to 0.1%, The balance is zinc. The rare earth lanthanides are neodymium and lanthanum. Addin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com