A kind of cu/paa composite film and its preparation method and application

A composite membrane and H3PO4 technology is applied in the field of bioactive materials and their preparation, which can solve the problems of difficult bioactive substance loading, effective control, etc., and achieve the effects of simple and efficient preparation method, low cost, and promotion of osteoblast proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

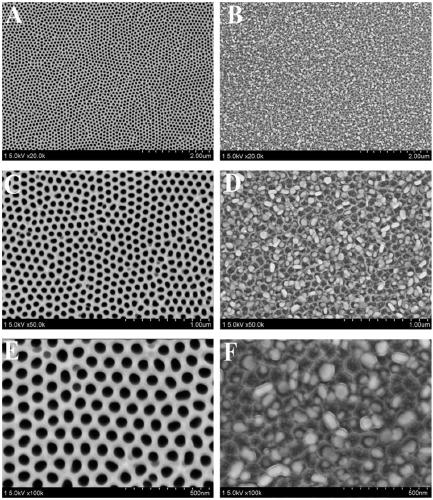

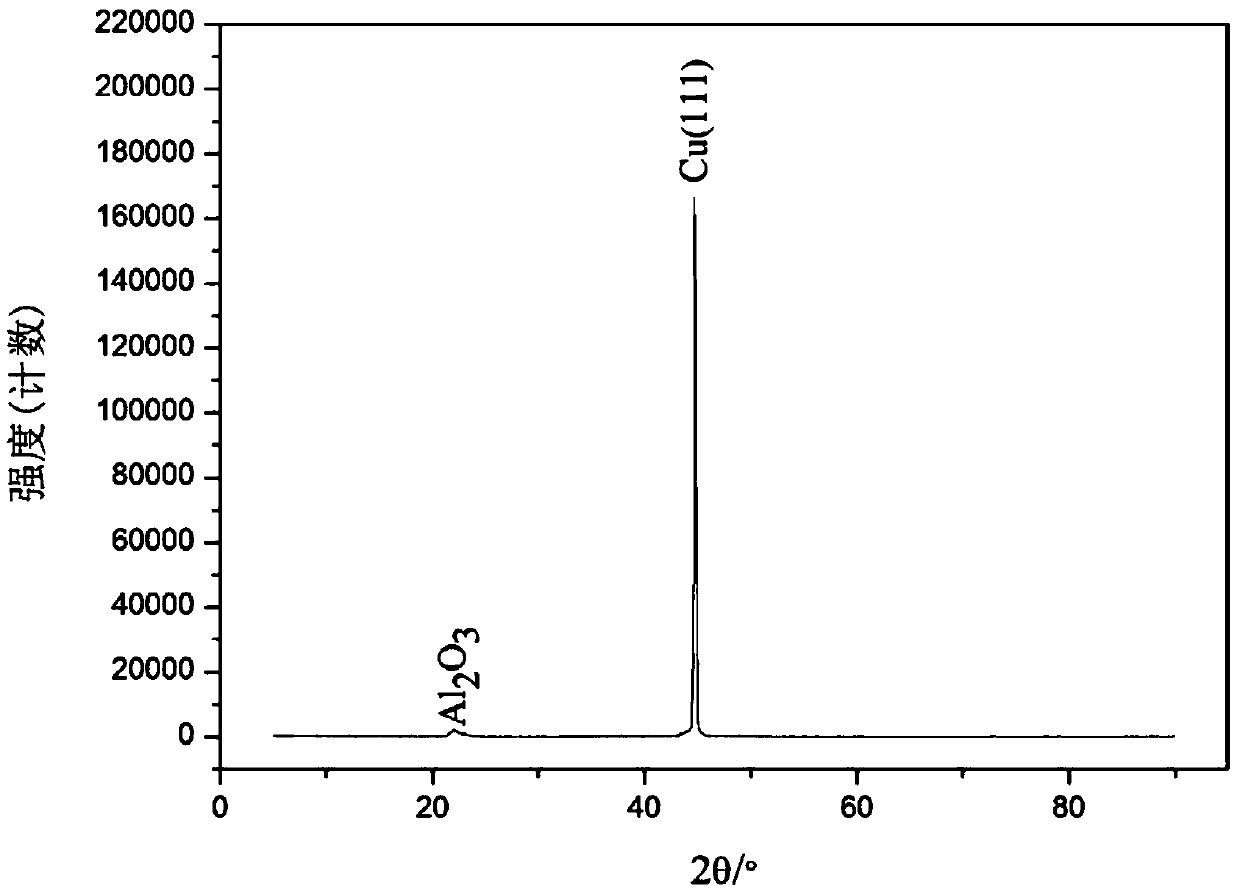

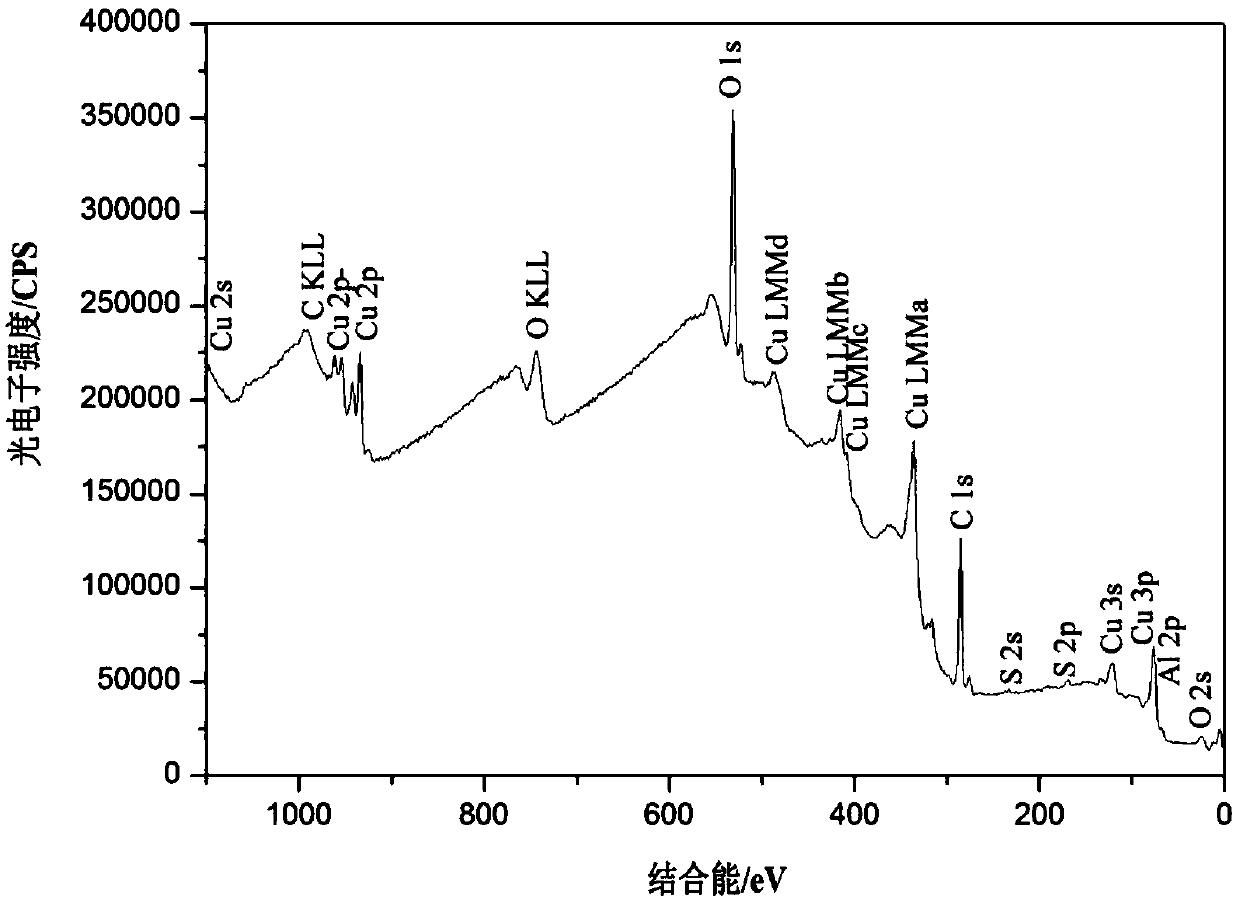

[0036] (1) The high-purity aluminum sheet is used as the anode, the graphite plate is used as the counter cathode, and 0.4MC with 40V DC constant voltage at 2°C is used 2 h 2 o 4 2H 2 Carry out two anodic oxidations in O solution, the first anodic oxidation 2h, the second anodic oxidation 3h, obtain PAA;

[0037] (2) Immediately after the secondary anodic oxidation, the step-down step is performed, the drop rate is 1V / 30s, the lower limit of the step-down step is 2V, and the deionized water is rinsed;

[0038] (3) At 45°C, using 5wt% H 3 PO 4 The solution expands the pores of the aluminum oxide film for 55 minutes;

[0039] (4) Prepare CuSO in advance 4 ·5H 2 O concentration is 10.0wt.%, (NH 4 ) 2 SO 4 The concentration is 2.0wt.%, H 3 BO 3A mixed solution with a concentration of 2.5wt.% is used as an electrodeposition solution;

[0040] (5) The PAA obtained in step (3) was washed with deionized water and immediately immersed in the electrodeposition solution, and...

Embodiment 2

[0052] (1) With high-purity aluminum sheet as anode and graphite plate as counter cathode, 0.4MC with 40V DC constant voltage at 0°C 2 h 2 o 4 2H 2 Carry out anodic oxidation twice in O solution, the first anodic oxidation 3h, the second anodic oxidation 3h, obtain PAA;

[0053] (2) Immediately after the secondary anodic oxidation, the step-down step is performed, the drop rate is 2V / 30s, the lower limit of the step-down step is 6V, and the deionized water is rinsed;

[0054] (3) At 45°C, using 5wt% H 3 PO 4 The solution expands the pores of the aluminum oxide film for 65 minutes;

[0055] (4) Prepare CuSO in advance 4 ·5H 2 O concentration is 9.0wt.%, (NH 4 ) 2 SO 4 The concentration is 1.5wt.%, H 3 BO 3 A mixed solution with a concentration of 2.0wt.% is used as an electrodeposition solution;

[0056] (5) The PAA obtained in step (3) was washed with deionized water and immediately immersed in the electrodeposition solution, and the graphite plate was used as the...

Embodiment 3

[0062] (1) With the graphite plate as the cathode and the high-purity aluminum sheet as the anode, at 0°C at 0.4M C 2 h 2 o 4 2H 2 O solution was anodized twice with 40V DC constant voltage, the first anodized for 2h, and the second anodized for 2.5h to obtain PAA;

[0063] (2) Immediately after the secondary anodic oxidation, the step-down step is performed, the drop rate is 2V / 30s, the lower limit of the step-down step is 4V, and the deionized water is rinsed;

[0064] (3) At 45°C, using 5wt% H 3 PO 4 The solution expands the pores of the aluminum oxide film for 60 minutes;

[0065] (4) Preparation of CuSO 4 ·5H 2 O concentration is 8.0wt.%, (NH 4 ) 2 SO 4 The concentration is 1.0wt.%, H 3 BO 3 A mixed solution with a concentration of 2.0wt.% is used as an electrodeposition solution;

[0066] (5) The PAA obtained in step (3) was washed with deionized water and immediately immersed in the electrodeposition solution, and the graphite plate was used as the counter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com