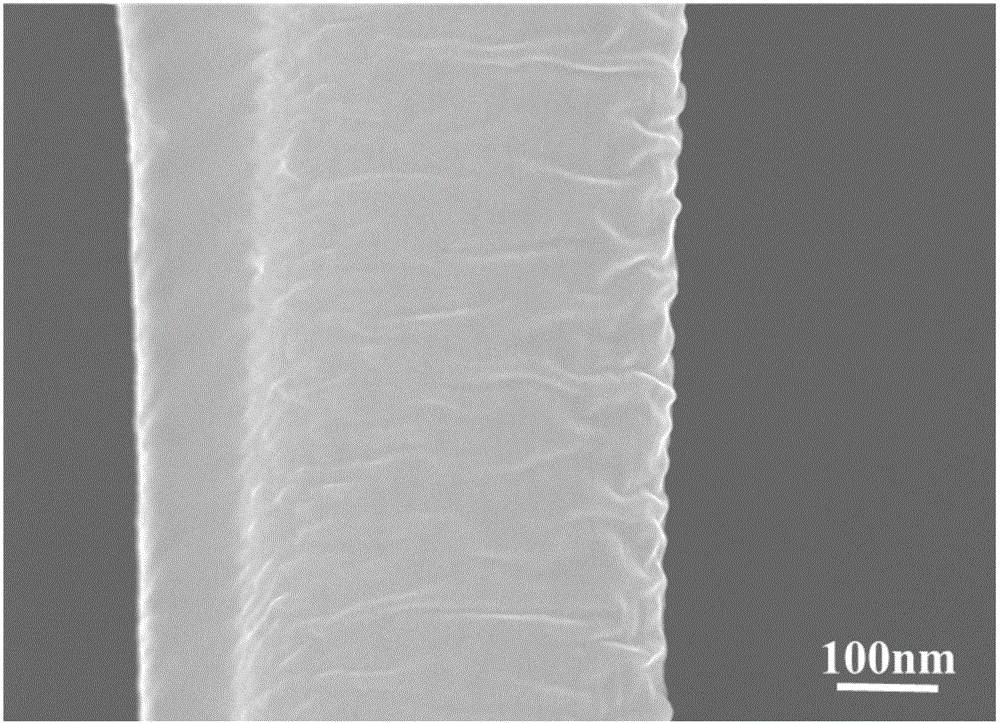

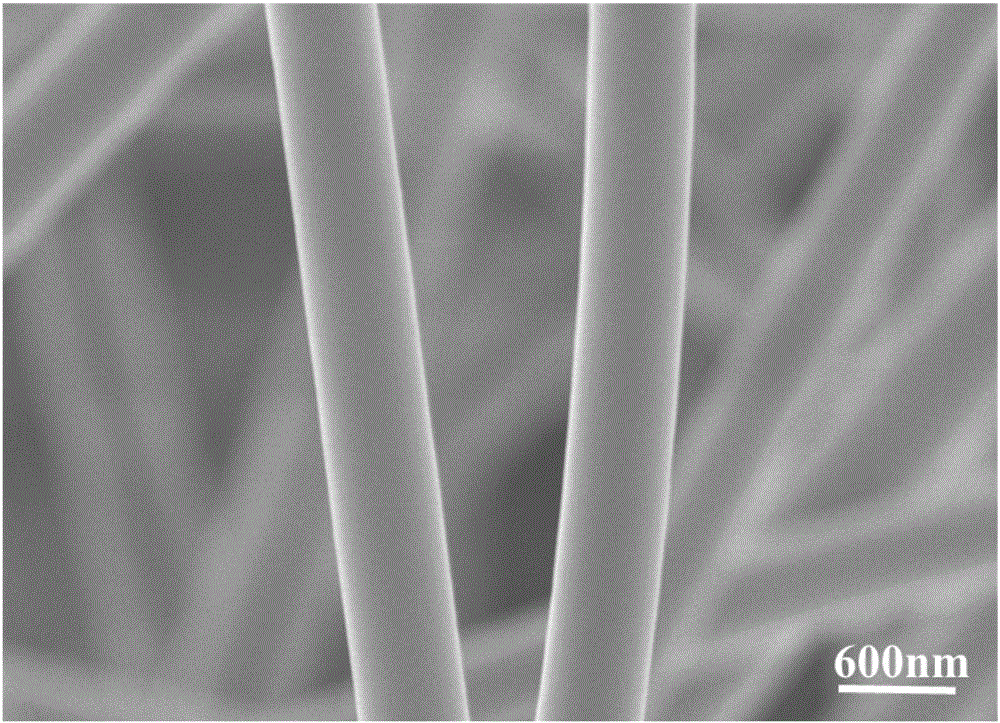

Method for preparing graphene/silica nanocomposite fiber through coaxial electrostatic spinning

A nanocomposite fiber and coaxial electrospinning technology, which is applied in fiber processing, filament/wire forming, fiber chemical characteristics, etc., can solve the problems of graphene dispersion and synergistic effect, and achieve diameter Small, conducive to industrial scale-up, and the effect of improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

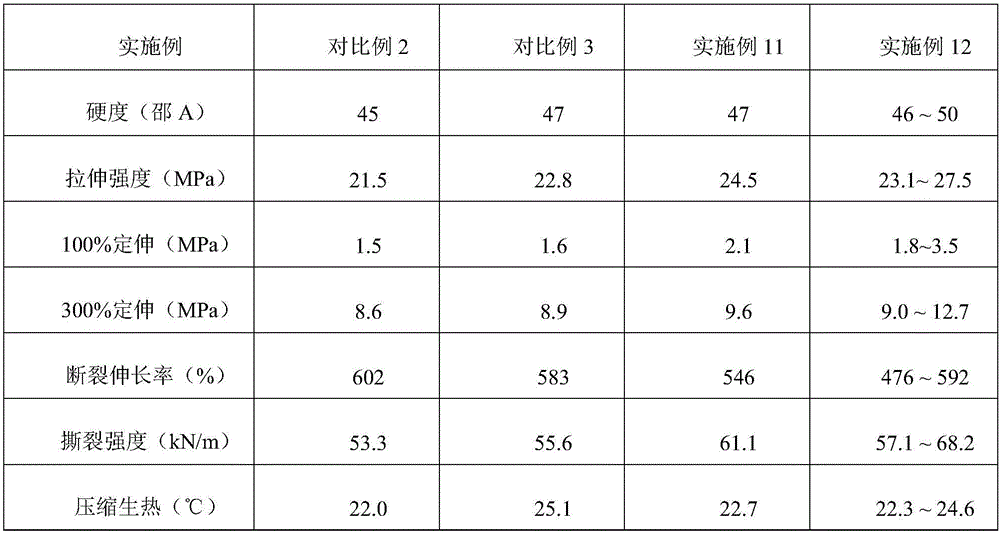

Examples

Embodiment 1

[0021] (1) Outer layer solution

[0022] Weigh 1.5g of graphite oxide, dissolve it in 100mL deionized water and ultrasonically treat it to obtain a graphene oxide dispersion; weigh 35.0g of PVP and 12.5g of DMSO, mix and stir evenly; mix the above two solutions, and stir under a magnetic stirrer 3h, to obtain the outer layer spinning solution.

[0023] (2) inner layer solution

[0024] Weigh 25.0g of TEOS, 8.2g of absolute ethanol, 15g of dilute hydrochloric acid with a concentration of 2.0mol / L, mix and stir evenly; weigh 5.0g of PVP, DMF18.0g, mix and stir evenly; mix the above two solutions, Stir for 8 hours under a magnetic stirrer to obtain an inner layer spinning solution.

[0025] (3) Coaxial electrospinning was performed using a spinning device consisting of a high-voltage power supply and a syringe pump. The parameters of the spinning equipment are as follows: the propulsion rate of the inner layer solution is 1.0mL / h, and the inner diameter of the spinneret is 0.7...

Embodiment 2

[0028] (1) Outer layer solution

[0029] Weigh 0.1g of graphene, dissolve it in 50mL of deionized water and 10mL of absolute ethanol, and obtain a graphene dispersion by ultrasonic treatment; weigh 1.2g of PLA, 4.0g of THF, and 0.8g of DMSO, mix and stir evenly; mix the above two solutions Mix and stir for 1 h to obtain the outer layer spinning solution.

[0030] (2) inner layer solution

[0031] Weigh 80.0g of TEOS, 1.8g of absolute ethanol, 3.6g of dilute hydrochloric acid with a substance concentration of 1.2mol / L, mix and stir evenly; weigh 1.8g of PLA, THF 6.5g, 0.5g of DMSO, mix and stir evenly; The two solutions were mixed and magnetically stirred for 3 hours to obtain the inner layer spinning solution.

[0032] (3) The propulsion rate of the inner layer solution is set to be 1.6mL / h, and the inner diameter of the spinneret is 0.8mm; the propulsion rate of the outer layer solution is 4.2ml / h, and the inner diameter of the spinneret is 1.5mm; the driving voltage is 20k...

Embodiment 3

[0035] (1) Outer layer solution

[0036]Weigh 5.0g of graphite oxide, dissolve it in 80mL of deionized water and 10mL of absolute ethanol, and obtain a graphene oxide dispersion by ultrasonic treatment; weigh 1.5g of PMA, 5.0g of THF, and 0.9g of DMF, and mix and stir evenly; The solutions were mixed and magnetically stirred for 3 hours to obtain the outer layer spinning solution.

[0037] (2) inner layer solution

[0038] Weigh 5.0g of TMOS, 0.5g of absolute ethanol, 2.0g of dilute hydrochloric acid with a substance concentration of 0.5mol / L, mix and stir evenly; weigh 2.0g of PMA, THF 4.6g, DMF 1.0g, mix and stir evenly; The two solutions were mixed and magnetically stirred for 2 hours to obtain the inner layer spinning solution.

[0039] (3) The propulsion rate of the inner layer solution is set to 0.8ml / h, and the inner diameter of the spinneret is 0.6mm; the propulsion rate of the outer layer solution is 1.4ml / h, and the inner diameter of the spinneret is 1.0mm; the dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com