A kind of paper printability improver and preparation method thereof

A technology of printing suitability and improver, which is applied in papermaking, paper coating, textiles and papermaking, etc. It can solve the problems of low water resistance efficiency, limitation of paper printing suitability improvement, physical injury of workshop operators, etc., and achieve improvement Ink fixation, reduction of printing mottling, improvement of anti-wet napping and anti-humidity frictional resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

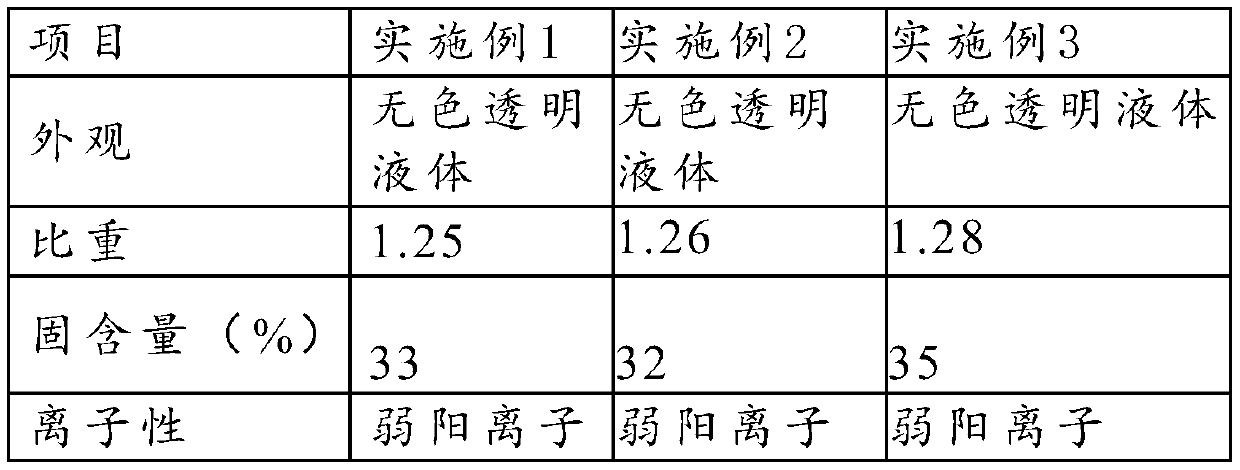

Embodiment 1

[0035] Select 50 parts of zirconium oxychloride, 70 parts of sodium acetate, 50 parts of glacial acetic acid, 0.03 parts of tartaric acid, and 500 parts of water; add sodium acetate to the reaction kettle, keep the temperature at 10-30°C and stir, then add zirconium oxychloride Add water to prepare a zirconium oxychloride solution, stir continuously, add the zirconium oxychloride solution dropwise in the reaction kettle, add dropwise for 30 minutes, keep stirring, keep warm at 30°C for 2 hours, and form a polyzirconyl acetate solution; in another reaction kettle Add glacial acetic acid to it, stir at the same temperature at 10-30°C, add the remaining zirconium oxychloride solution dropwise into the glacial acetic acid solution for 30 minutes, keep stirring, and keep warm at 30°C for 2 hours to form a zirconium acetate solution; Add the zirconium acetate solution into the polyzirconyl acetate solution, add tartaric acid, stir continuously, and keep it warm for 30 minutes; then r...

Embodiment 2

[0037] Select 100 parts of zirconium oxychloride, 100 parts of potassium acetate, 100 parts of glacial acetic acid, 0.05 parts of tartaric acid, and 600 parts of water; add sodium acetate to the reaction kettle, keep the temperature at 10-30°C and stir, then mix the zirconium oxychloride Add water to prepare a zirconium oxychloride solution, stir continuously, add the zirconium oxychloride solution dropwise in the reaction kettle, add dropwise for 30 minutes, keep stirring, keep warm at 40°C for 2 hours, and form a polyzirconyl acetate solution; in another reaction kettle Add glacial acetic acid to it, stir at the same temperature at 10-30°C, add the remaining zirconium oxychloride solution dropwise into the glacial acetic acid solution for 30 minutes, keep stirring, and keep warm at 40°C for 2 hours to form a zirconium acetate solution; Add the zirconium acetate solution into the polyzirconyl acetate solution, add tartaric acid, stir continuously, and keep it warm for 30 minut...

Embodiment 3

[0039] Select 100 parts of zirconium oxychloride, 50 parts of sodium zirconate, 70 parts of potassium acetate, 80 parts of glacial acetic acid, 0.08 parts of tartaric acid, and 800 parts of water; add sodium acetate to the reaction kettle, keep the temperature at 10-30 °C and stir , then add zirconium oxychloride to water to prepare zirconium oxychloride solution, stir constantly, add dropwise zirconium oxychloride solution in the reaction kettle, add dropwise for 30min, keep stirring, keep warm at 35°C for 2h, and form polyzirconyl acetate solution Add glacial acetic acid into another reaction kettle, stir at the same temperature at 10-30°C, add the remaining zirconium oxychloride solution dropwise in the glacial acetic acid solution, add dropwise for 30 minutes, keep stirring, and keep warm at 35°C for 2 hours, Form a zirconium acetate solution; add the zirconium acetate solution into the polyzirconyl acetate solution, add tartaric acid, stir continuously, and keep it warm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com