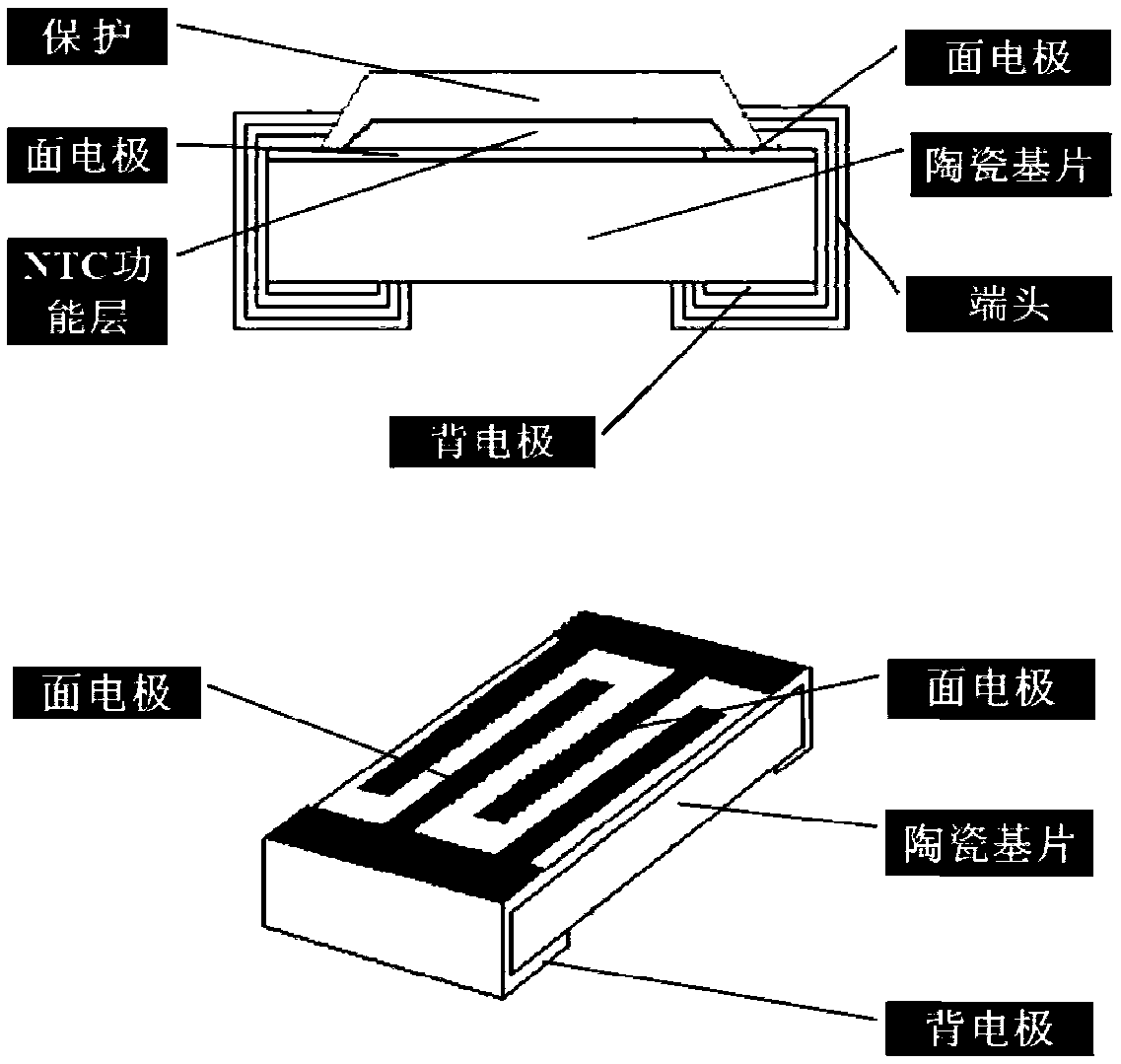

Preparation method of a microchip linear negative temperature coefficient thermistor

A thermistor and negative temperature coefficient technology, which is applied in the direction of resistors, resistor manufacturing, resistor chip manufacturing, etc., can solve the problems of high product resistance, uneven distribution of product resistance, low pass rate, etc., and achieve stability Good performance and stable NTC effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Ingredients and stirring

[0031] Weigh fluororubber (0.9) and conductive carbon black (0.1) in proportion, dissolve fluororubber with butyl acetate solvent, add silane coupling agent, add conductive carbon black under stirring state, according to product TCR value and resistance value Adjust the formula until the carbon black is uniformly dispersed in the fluororubber solution to form a slurry-like polymer composite.

[0032] (2) Configuration cast material

[0033] The uniformly stirred polymer composite material slurry is made into a casting material. The specific implementation method is to add an appropriate amount of butyl acetate (quantified according to the viscosity) to the polymer composite slurry, stir for about 2 hours, and filter to obtain the casting material.

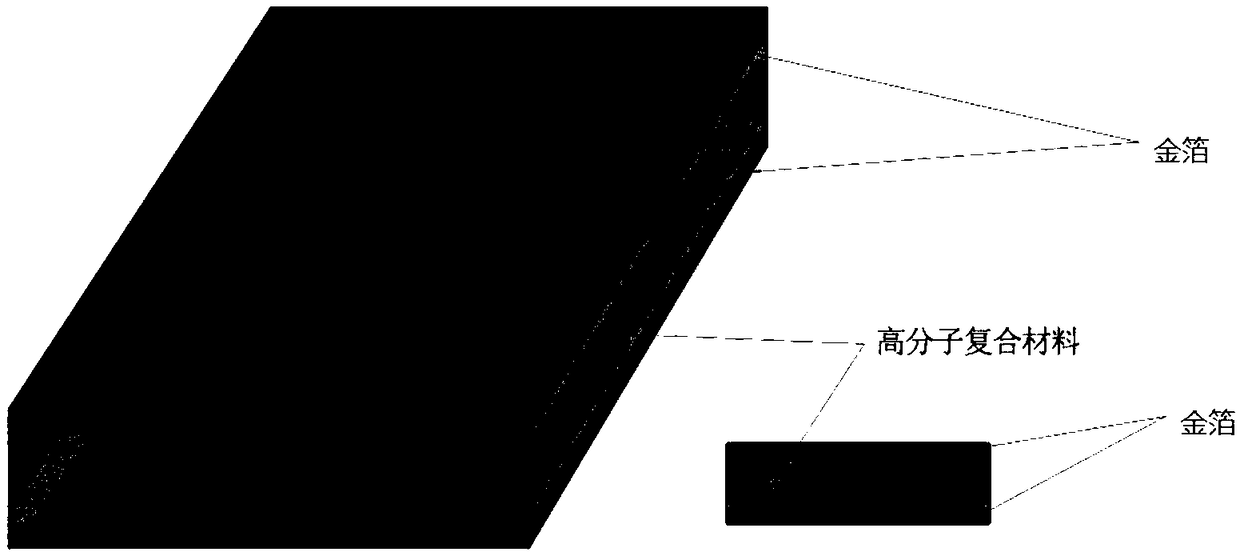

[0034] (3) Casting and lamination

[0035]The thermistor polymer composite substrate can be prepared by tape casting, gold foil lamination, isostatic pressing, hot pressing and ultraviolet ra...

Embodiment 2

[0046] The formula in the batching and ball milling process is changed to: 0.75 parts of fluororubber and 0.25 parts of conductive carbon black, appropriate amount of coupling agent, and appropriate amount of butyl acetate solvent. Other process conditions remain unchanged, and finally choose 8 chip thermistor products, and their electrical performance test results are shown in Table 2.

[0047] Microchip linear thermistor sample electrical properties prepared after table 2 formula changes

[0048]

[0049] It can be seen from the test results in Table 2 that the room temperature resistance of the microchip thermistor is about 82Ω, the TCR value is about 6000ppm / °C, and the average deviation is small. After the film prepared by casting method is laminated and isostatically pressed, the dispersion of carbon black in the fluororubber is excellent and the uniformity is good, so that the resistance value of the product has high precision, good stability and excellent performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com