One-dimensional In<2>O<3>/C fiber composite material, and preparation method and application thereof

A fiber composite material and composite material technology, applied in the fields of new energy, electrochemistry, and energy storage materials, can solve the problems of poor cycle stability and low specific capacity, improve cycle performance and service life, and the synthesis method is simple and environmentally friendly. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

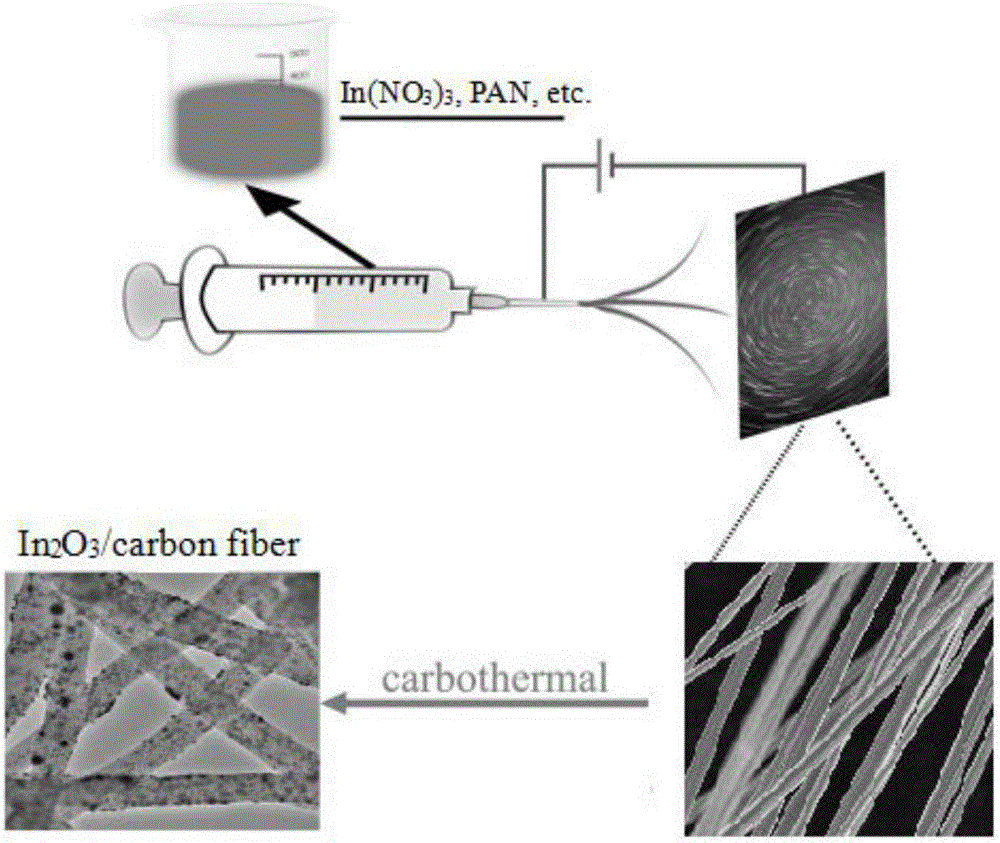

[0034] The one-dimensional In 2 o 3 The preparation method of / C fiber composite material, comprises the following steps:

[0035] (1) Mix indium salt, polyacrylonitrile and N,N-dimethylformamide according to the mass ratio of 0.75~1:1~1.25:10~10.75 to prepare the indium salt precursor spinning solution; the indium salt is preferably Be indium nitrate, the mass ratio is preferably 1:1:10.5;

[0036] (2) Spinning the precursor spinning solution described in step (1) under high pressure to obtain a precursor one-dimensional fiber; the spinning voltage is 15-22KV, and the injection rate is 0.5-1.2mm / min; preferably The spinning voltage is 22KV, and the injection rate is 1.2mm / min;

[0037] (3) Calcining the one-dimensional fiber described in step (2) in an inert atmosphere, preferably in a nitrogen atmosphere, at a heating rate of 5°C / min to 500-650°C for 3-5 hours, and then cooling to obtain carbonized fibers;

[0038] (4) Calcining the carbonized fibers described in step (3) ...

Embodiment 1

[0043] a kind of like figure 1 The one-dimensional In of the present invention shown 2 o 3 The preparation method of / C fiber composite material, comprises the following steps:

[0044] (1) Preparation of spinning precursor solution: weigh indium nitrate (In(NO 3 ) 3 ), polyacrylonitrile (PAN) and N,N-dimethylformamide (DMF), stirred for 24 hours, and mixed uniformly to obtain a spinning precursor solution.

[0045] (2) Preparation of fiber precursor: the spinning precursor solution prepared in the above step (1) was spun in an electrospinning device with a voltage of 22KV and a bolus injection rate of 1.2mm / min.

[0046] (3) Preparation of fiber with stable structure: The fiber precursor described in (2) above was calcined in nitrogen at a temperature of 650° C. for 5 hours to obtain a fiber with stable structure.

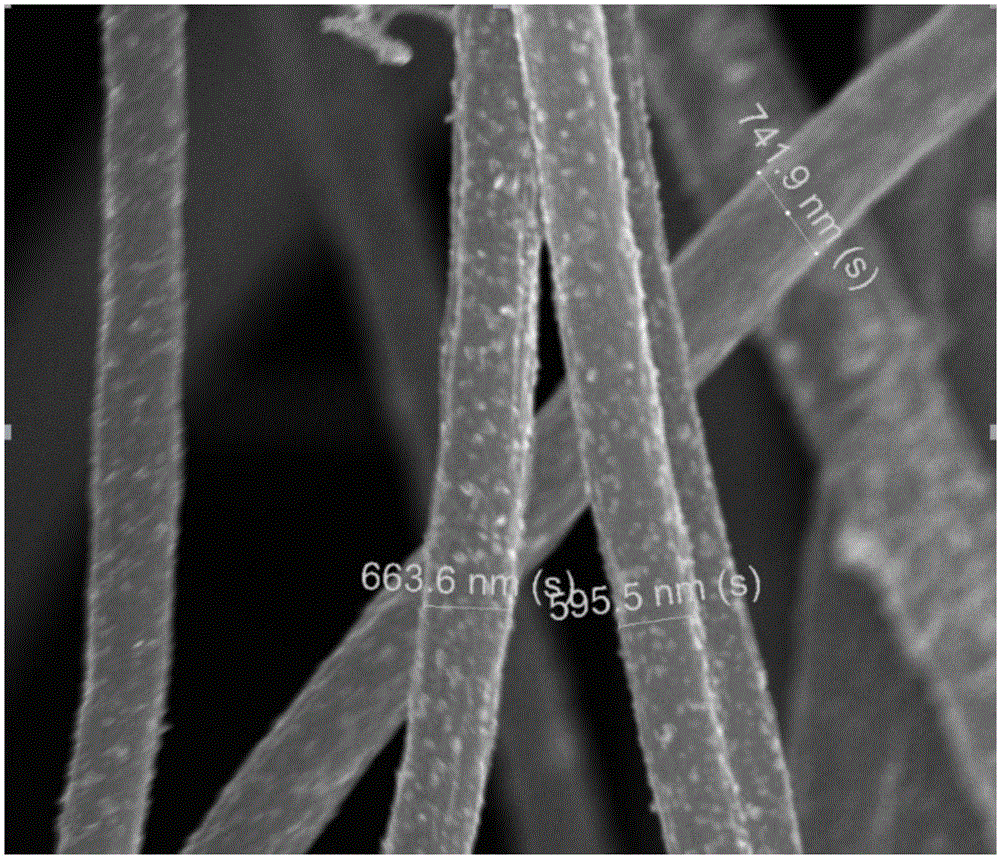

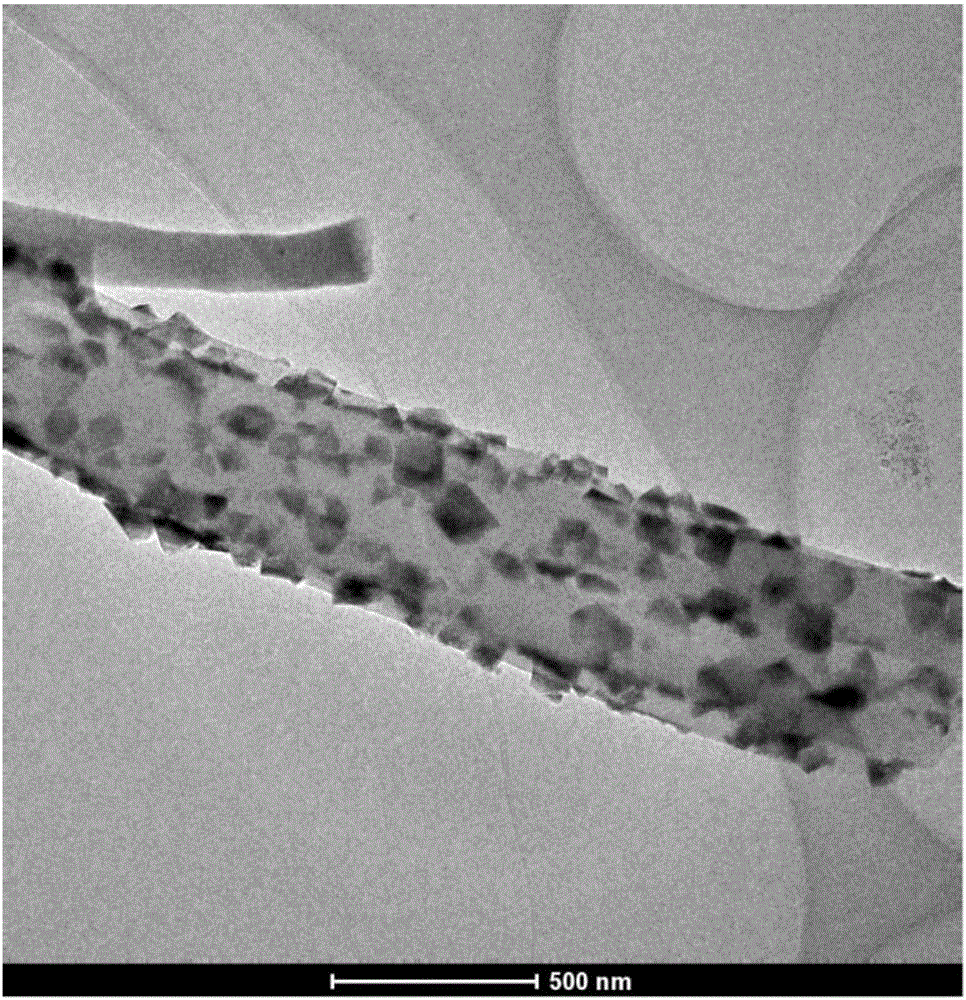

[0047] (4) One-dimensional In 2 o 3 Preparation of / C fiber composite lithium ion negative electrode material: the structurally stable fiber obtained in th...

Embodiment 2

[0051] a kind of like figure 1 The one-dimensional In of the present invention shown 2 o 3 The preparation method of / C fiber composite material, comprises the following steps:

[0052] (1) Preparation of spinning precursor solution: Weigh indium nitrate (In(NO 3 ) 3 ), polyacrylonitrile (PAN) and N,N-dimethylformamide (DMF), stirred for 24 hours, and mixed uniformly to obtain a spinning precursor solution.

[0053] (2) Preparation of fiber precursor: the spinning precursor solution prepared in the above step (1) was spun in an electrospinning device with a voltage of 20KV and a bolus rate of 1mm / min.

[0054] (3) Preparation of fiber with stable structure: the fiber precursor described in (2) above was calcined in nitrogen at a temperature of 600° C. for 4 hours to obtain a fiber with stable structure. .

[0055] (4) One-dimensional In 2 o 3 Preparation of / C fiber composite lithium ion negative electrode material: the structurally stable fiber obtained in the above (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com