Preparation method for graphene-lithium composite electrode material

A composite electrode and graphene technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of unsatisfactory Coulombic efficiency and cycle stability, and the influence of specific capacity surface state, so as to improve capacity utilization and charge and discharge performance The effect of enhancing and increasing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

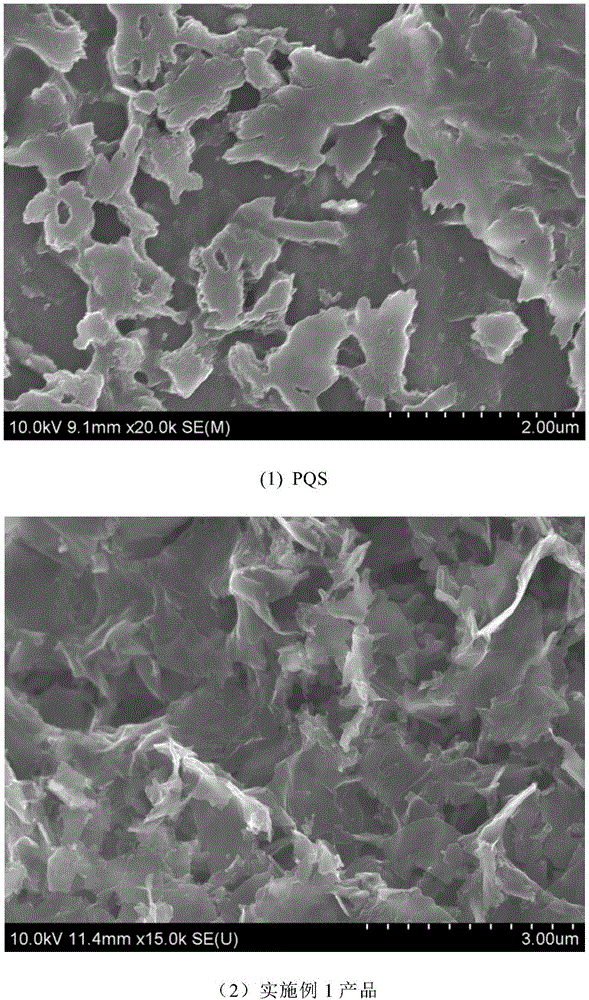

Embodiment 1

[0029] This embodiment relates to a method for preparing an improved organic quinone compound / conductive polymer / graphene lithium battery positive electrode, the method comprising the following steps:

[0030] Step 1, premix 0.1435g of sulfonate of phenanthrenequinone sulfonate with 100mL of deionized water, stir at room temperature until the raw material is completely dissolved, and record it as solution A;

[0031] Step 2, premix 0.2g graphene oxide with 100mL deionized water, stir at room temperature until the raw materials are completely dissolved, and record it as solution B;

[0032] Step 3, take 3.75mL of solution A and 3.75mL of solution B, stir at room temperature until completely mixed, and record it as mixed solution C;

[0033] Step 4, drop 0.1005 g of pyrrole into the mixed solution C while stirring to obtain a dark yellow solution E;

[0034] Step 5, using stainless steel mesh as the counter electrode, at 0.5mA / cm 2 After 40 minutes of galvanostatic deposition ...

Embodiment 2

[0038] This embodiment relates to a method for preparing an improved organic quinone compound / conductive polymer / graphene lithium battery positive electrode, the method comprising the following steps:

[0039] Step 1, premix 0.1435g of sulfonate of phenanthrenequinone sulfonate with 100mL of deionized water, stir at room temperature until the raw material is completely dissolved, and record it as solution A;

[0040] Step 2, premix 0.2g graphene oxide with 100mL deionized water, stir at room temperature until the raw materials are completely dissolved, and record it as solution B;

[0041] Step 3, take 3.75mL of solution A and 1.875mL of solution B, stir at room temperature until completely mixed, and record it as mixed solution C;

[0042] Step 4, drop 0.0646g of pyrrole into the mixed solution C while stirring to obtain a dark yellow solution E;

[0043] Step 5, using stainless steel mesh as the counter electrode, at 0.5mA / cm 2After 60 minutes of galvanostatic deposition a...

Embodiment 3

[0047] This embodiment relates to a method for preparing an improved organic quinone compound / conductive polymer / graphene lithium battery positive electrode, the method comprising the following steps:

[0048] Step 1, premix 0.1435g of sulfonate of phenanthrenequinone sulfonate with 100mL of deionized water, stir at room temperature until the raw material is completely dissolved, and record it as solution A;

[0049] Step 2, premix 0.2g graphene oxide with 100mL deionized water, stir at room temperature until the raw materials are completely dissolved, and record it as solution B;

[0050] Step 3, take 3.75mL of solution A and 7.5mL of solution B, stir at room temperature until completely mixed, and record it as mixed solution C;

[0051] Step 4, drop 0.0861g of pyrrole into the mixed solution C while stirring to obtain a dark yellow solution E;

[0052] Step 5, using stainless steel mesh as the counter electrode, at 1mA / cm 2 After 40 minutes of galvanostatic deposition at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com