Self-circulating air cathode microbial fuel cell and method based on bubble buoyancy

An air cathode and fuel cell technology, applied in the direction of biochemical fuel cells, etc., can solve the problems of energy consumption increase and energy loss, and achieve the effects of low cost, reduced energy consumption, and improved battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

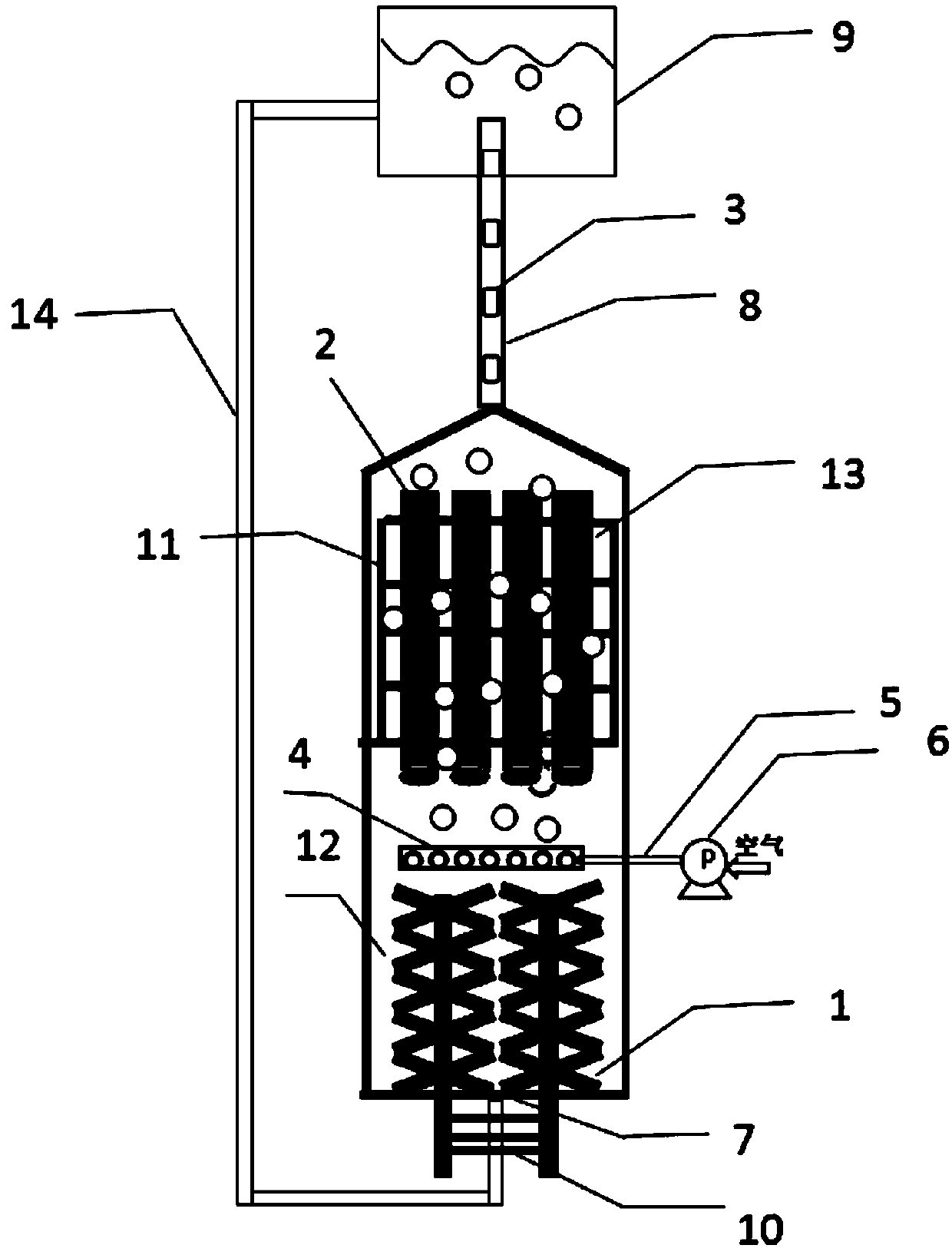

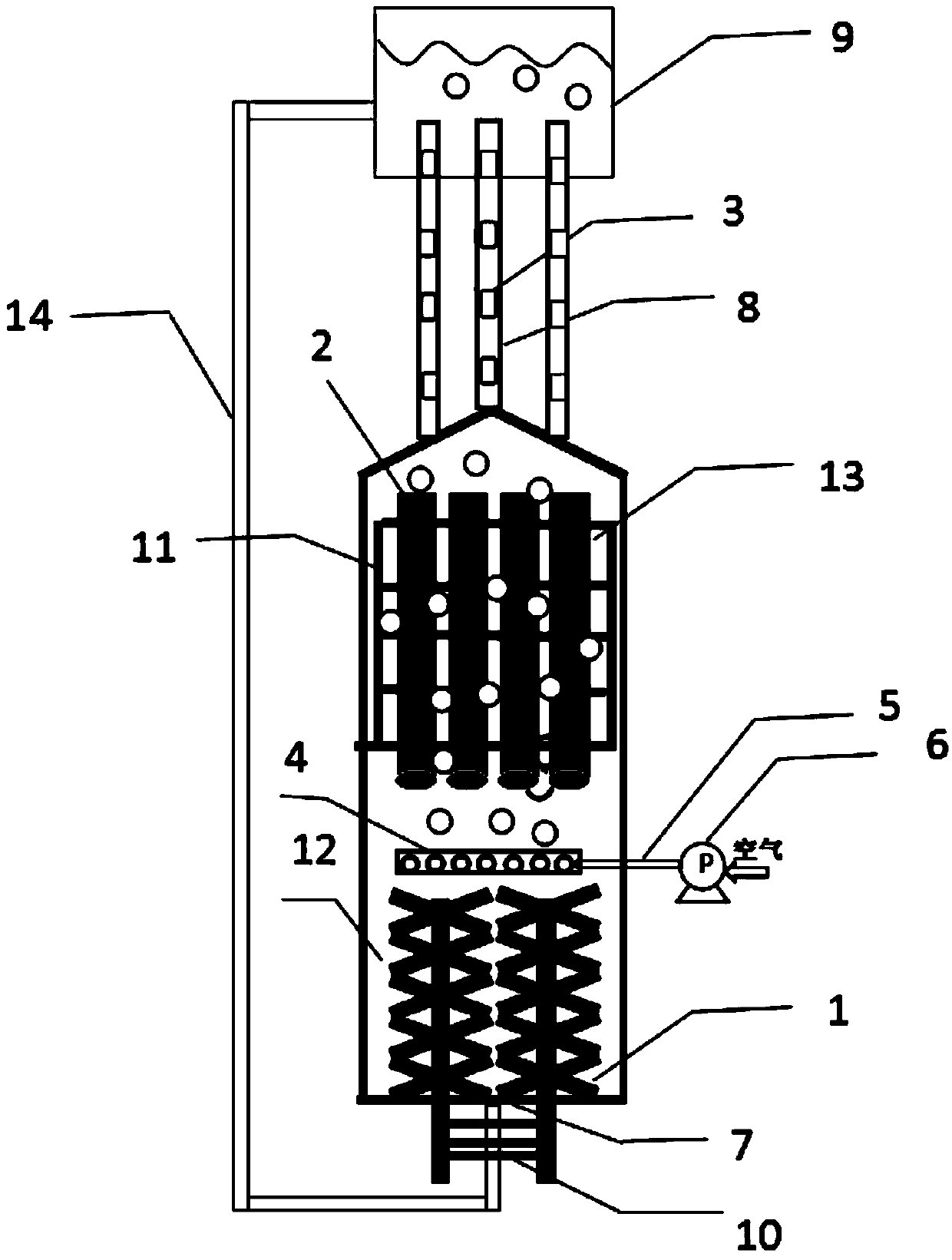

[0020] See figure 1 , A self-circulating air cathode microbial fuel cell based on bubble buoyancy, comprising an anode chamber 12 and a cathode chamber 13; the cathode chamber 13 is located above the anode chamber 12, and the cathode chamber 13 and the anode chamber 12 is connected; the anode chamber 12 is provided with an anode electrode, the anode electrode is composed of a number of vertically arranged carbon brushes 1, all the carbon brushes are connected by the first titanium wire 10; the cathode chamber 13 is provided with a cathode electrode, The cathode electrode is composed of a number of bamboo charcoal tubes 2 arranged vertically. The outer walls of all the bamboo charcoal tubes 2 are wound with a second titanium wire 11 and connected by the second titanium wire 11; the anode chamber 12 and the cathode chamber 13 are arranged between There is a bubbling screen 4, which is connected to an external air pump 6 through a pipeline 5 to introduce air; the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com