Copper-based catalyst and preparation method and application thereof

A copper-based catalyst, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, ether preparation, etc., can solve the problems of poor stability, methyl bromide conversion rate, low dimethyl ether selectivity, deactivation, etc., and achieve performance Excellent, simple and controllable operation, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

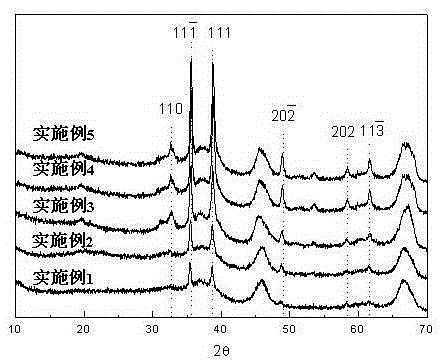

[0036] According to the ratio that isopropanol mass percentage is 3.3%, AEO-7 mass percentage is 1.6%, triethanolamine mass percentage is 0.7%, isopropanol, AEO-7, triethanolamine are added to deionized water, prepare solution; According to Cu The element accounts for 20% of the mass percentage of the catalyst, and the Zr element accounts for 1.2% of the catalyst mass percentage. Add copper nitrate and zirconium oxychloride to the solution, stir and dissolve completely to obtain an impregnation solution, and then carry out an equal-volume reaction with 10g of alumina carrier. Dipping, aging at room temperature for 8 hours, and drying at 80°C for 48 hours. The obtained material was placed in a tube furnace and heated to 145°C under nitrogen, treated with 50% water vapor-50% nitrogen mixture for 4 hours, switched to nitrogen, and purged for 2 hours. Then the treated material was calcined at 550°C for 10h; the catalyst was prepared, and the XRD results were shown in figure 1 . ...

Embodiment 2

[0038] According to the ratio of 4.8% by mass percentage of isopropanol, 0.9% by mass percentage of AEO-7, and 1.8% by mass percentage of triethanolamine, isopropanol, AEO-7, and triethanolamine are added to deionized water to prepare a solution; The element accounted for 15% by mass of the catalyst, and the Zr element accounted for 3.5% by mass of the catalyst. Add copper nitrate and zirconium oxychloride to the solution, stir and dissolve completely to obtain an impregnating solution, and then carry out an equal-volume Dipping, aging at room temperature for 10 hours, and drying at 120°C for 24 hours. The obtained material was placed in a tube furnace and heated to 130° C. under nitrogen, treated with 60% water vapor-40% nitrogen mixture for 2.5 hours, switched to nitrogen, and purged for 2 hours. Then the treated material was calcined at 600°C for 8h; the catalyst was prepared, and the XRD results were shown in figure 1 . The most intense X-ray diffraction When the cryst...

Embodiment 3

[0040] According to the ratio that isopropanol mass percentage is 5%, AEO-7 mass percentage is 1.5%, triethanolamine mass percentage is 1.3%, isopropanol, AEO-7, triethanolamine are added to deionized water, prepare solution; According to Cu The element accounts for 15% of the mass percentage of the catalyst, and the Zr element accounts for 2.2% of the catalyst mass percentage. Add copper nitrate and zirconium oxychloride to the solution, stir and dissolve completely to obtain an impregnating solution, and then carry out an equal volume with 10g of alumina carrier. Dipping, aging at room temperature for 9 hours, and drying at 90°C for 40 hours. The obtained material was placed in a tube furnace and heated to 130° C. under nitrogen, treated with 55% water vapor-45% nitrogen mixture for 3 hours, switched to nitrogen, and purged for 2 hours. Then the treated material was calcined at 700°C for 8h; the catalyst was prepared, and the XRD results were shown in figure 1 . The most i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com