Manufacturing method of diamond sandwich-type enhanced tungsten carbide composite spherical crown button

A cemented carbide, sandwich-type technology, applied in construction and other directions, can solve the problems of aggravating the fracture brittleness of the material, increasing the interfacial gap between the bezels, and decreasing the strength, and achieves broad application prospects, high cutting speed, and the effect of saving consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

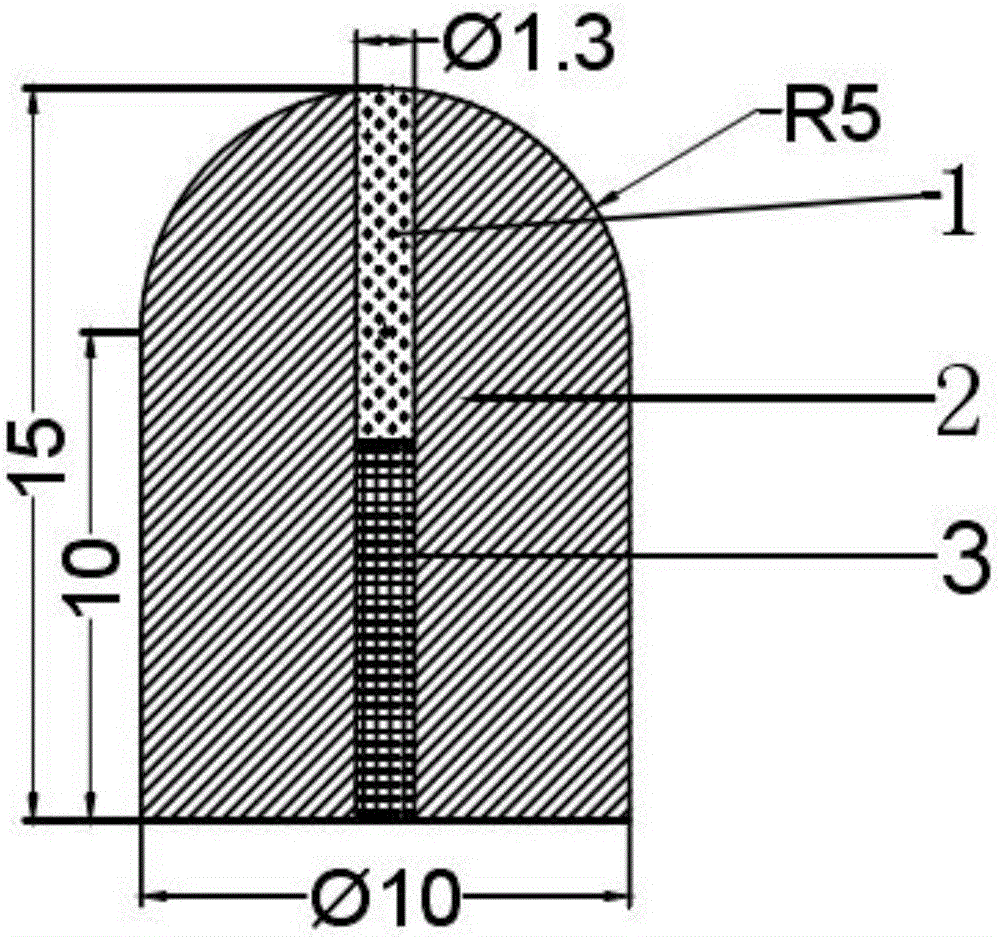

[0028] Batch (5000) preparation diameter φ10mm (see figure 1 ), with a height of 15mm and a spherical shape of R5mm at the top, a synthetic diamond sandwich button should be carried out as follows:

[0029] 1. Design the YG11C cemented carbide button drawing with the center hole, the small hole diameter of the button is calculated according to d / D≤0.13~0.15, d=(0.13~0.15)×10mm=(1.3~1.5)mm, select d=1.30±0.1mm, according to the small hole size and related parameters, order 5000 ball teeth with holes from a professional manufacturer of cemented carbide.

[0030] 2. Configure 1.5Kg of synthetic diamond particles and copper alloy mixed powder, actual weighing: JR-2 type synthetic diamond powder, particle size 0.1-0.2mm, 54% (mass); 663 bronze alloy powder, particle size -320 mesh, 38% (mass); ferrochrome powder (chromium content 8%), particle size-320 mesh, 6% (mass); titanium ferro powder (titanium content 10%), particle size-320 mesh, 2% (mass). According to the above powder, ...

Embodiment 2

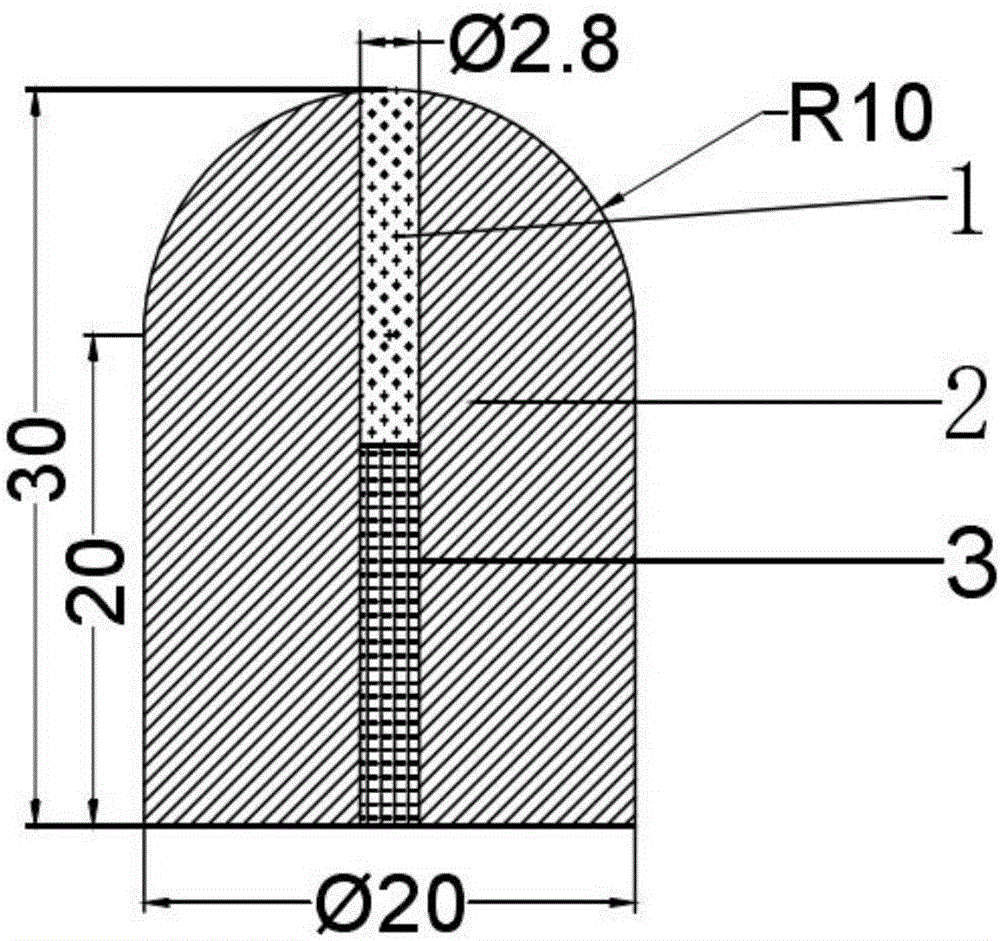

[0035] Batch (5000) preparation diameter φ20mm (see figure 2 ), with a height of 30mm and a spherical shape of R10mm at the top, a synthetic diamond sandwich button should be carried out as follows:

[0036] 1. Design the YG11C cemented carbide button drawing with the center hole, the small hole diameter of the button is calculated according to d / D≤0.13~0.15, d=(0.13~0.15)×20mm=(2.6~3.0)mm, select d=2.80±0.1mm, according to the small hole size and related parameters, order 5000 ball teeth with holes from a professional manufacturer of cemented carbide.

[0037] 2. Configure 12Kg of artificial diamond particles and copper alloy mixed powder, actual weighing: JR-2 type artificial diamond powder, particle size 0.1~0.2mm, 54% (mass); 663 bronze alloy powder, particle size-320 mesh, 38% ( mass); ferrochromium powder (chromium content 8%), particle size-320 mesh, 6% (mass); titanium ferro powder (titanium content 10%), particle size-320 mesh, 2% (mass). According to the above pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com