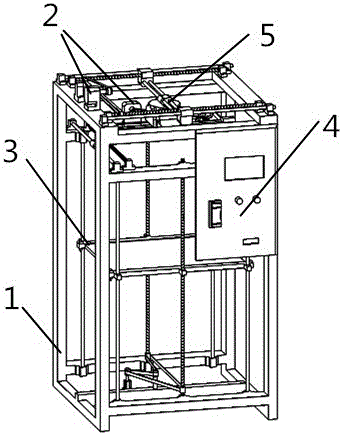

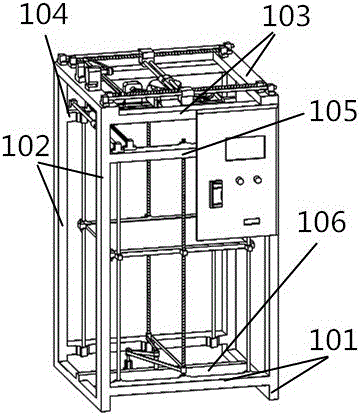

Multifunctional machining integrated machine for additives and consumables

A multi-functional technology of adding and subtracting materials, applied in the direction of additive processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of waste of resources, high cost, cumbersome processing procedures, etc., to avoid secondary positioning errors and save The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

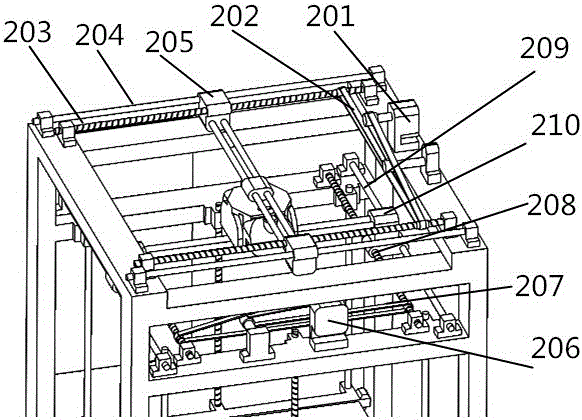

[0040] The 3D printing device includes a heating device and an extrusion device. The 3D printing device is firmly fixed on the function conversion support through the clamping slot, the power supply requirement is realized through the power interface, and the information transmission is realized through the information control interface, so that the 3D printing device can Follow the corresponding instructions to realize 3D printing processing operations. The nozzle material of the 3D printing device is brass, and the nozzle diameter is 0.2mm-0.5mm to choose from. It supports PLA, ABS, nylon and other consumables. The temperature of the printing nozzle is set to 210°C during printing. Between -230°C, the maximum diameter of the print size is 280mm, the height is 350mm, the thickness of the printing layer is 0.1mm-0.3mm, the printing speed is 10-300mm / s, and the temperature of the hot bed is 110°C-120°C. Parts are converted into STL format for printing, which can print parts with...

Embodiment 2

[0042] The laser processing device includes a laser emitting head, which gathers high-parallel, high-energy-density laser light onto the surface of the workpiece for thermal processing. The diameter of the laser spot can reach less than 1um, so it can perform very fine processing and realize Laser drilling, laser engraving, laser cutting, laser polishing and laser shock strengthening treatment, the laser processing device is firmly fixed on the function conversion support through the clamping slot, the power supply demand is realized through the power interface, and the information transmission is realized through the information control interface , so that the laser processing device can realize the laser processing operation according to the corresponding instructions. The laser wavelength used by the laser processing device is 445nm (blue light), and the laser power is 300mw, 500mw, 1000mw, 1600mw to choose from. 0.5mm, the lens adopts special optical coating glass, the lase...

Embodiment 3

[0044]The CNC machining device includes a CNC machining spindle and a machining tool. The CNC machining device is firmly fixed on the function conversion support through the clamping slot. The power supply requirement is realized through the power interface, and the information transmission is realized through the information control interface. The lower end of the CNC machining spindle can be Replacement of various processing tools, equipped with 15 processing tools, so that milling, drilling, grinding, boring, reaming, tapping and other CNC processing operations can be realized according to the corresponding instructions. The spindle speed of the CNC processing device is 300-500r / min , the maximum diameter of end milling is 10mm, the spindle taper hole is BT4-15mm, the diameter of the machining hole is 2-10mm, the positioning accuracy can reach 300mm / +0.075mm, and various processing operations can be realized. The point control function is mainly used for The hole processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com