The synthetic method of small grain alpo4-34 aluminum phosphate molecular sieve

A technology of aluminum phosphate molecular sieve and synthesis method, applied in the direction of molecular sieve characteristic aluminum phosphate, molecular sieve and alkali-exchanged phosphate and phosphorus compounds, etc., can solve the problem of large particle size of molecular sieve and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

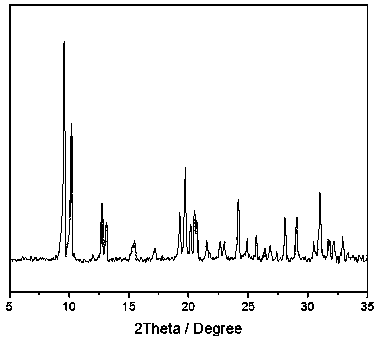

[0042] At 20°C, 1.69g of pseudoboehmite (Al 2 o 3 content of 68%) was added to 20g of deionized water, stirred and mixed evenly, followed by adding 2.43g of morpholine, 1.02g of tetraethylammonium hydroxide (TEAOH content of 25%), stirring at 100°C for 12h and cooling down, adding 2.52 g orthophosphoric acid (H 3 PO 4 content of 85%), 0.5ml of hydrofluoric acid (HF content of 40%), stirred for 30 minutes, added 1.4g of AlPO4-34 seed crystals (particle size range 5-300nm), pre-crystallized at 100°C for 12h and then transferred to 25ml Crystallize at 190°C for 72 hours in a stainless steel reaction kettle lined with polytetrafluoroethylene, cool to room temperature, and centrifuge for solid-liquid separation. The solid product is washed with deionized water until neutral, collected, and dried in air at 80°C for 12 hours to obtain product. The grain size of the product is 0.05-0.6μm, and the average particle size is 0.4μm.

Embodiment 2

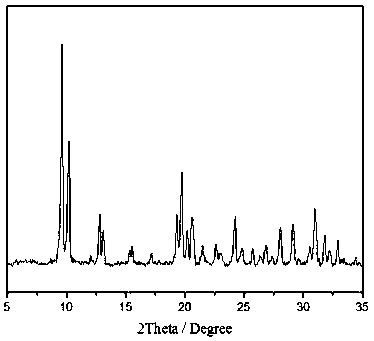

[0044] At 20°C, 1.69g of pseudoboehmite (Al 2 o 3 content of 68%) was added to 20g of deionized water, stirred and mixed evenly, followed by adding 2.90g of morpholine, 1.23g of tetraethylammonium hydroxide (TEAOH content of 25%), stirring at 100°C for 12h and cooling down, adding 2.52 g orthophosphoric acid (H 3 PO 4 content of 85%), 0.5ml of hydrofluoric acid (HF content of 40%), stirred for 30 minutes, added 1.5g of AlPO4-34 seed crystals (particle size range 5-300nm), pre-crystallized at 100°C for 12h and then transferred to 25ml Crystallize in a stainless steel reaction kettle at 190°C for 55 hours, centrifuge for solid-liquid separation, wash the solid product with deionized water until neutral, collect, and dry in air at 80°C for 12 hours to obtain the product. The grain size of the product is 0.1-0.9 μm, and the average particle size is 0.6 μm.

Embodiment 3

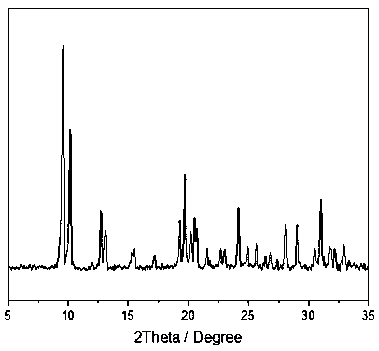

[0046] At 20°C, 1.69g of pseudoboehmite (Al 2 o 3 content of 68%) was added to 20g deionized water, after stirring and mixing evenly, 2.43g morpholine was added, stirred at 100°C for 12h, then cooled, and 2.52g orthophosphoric acid (H 3 PO 4 content is 85%), 0.5ml hydrofluoric acid (HF content is 40%), stirred for 30 minutes, added 1.4gAlPO 4 -34 seed crystals (particle size range 5-300nm), pre-crystallized at 100°C for 12h, then transferred to a 25ml stainless steel reactor for crystallization at 190°C for 72h, centrifuged for solid-liquid separation, and the solid product was washed with deionized water until neutral , collected, and dried in air at 80°C for 12 hours to obtain the product. The grain size of the product is 0.1-1μm, and the average particle size is 0.8μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com