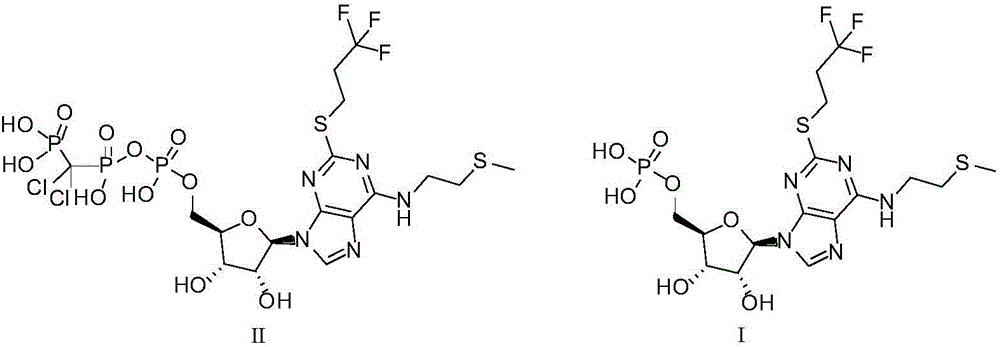

Method for purifying cangrelor intermediate

A purification method and intermediate technology, applied in organic chemistry methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of cumbersome operation of purification methods, unsuitable scale-up production, high equipment requirements, etc., and achieve short reaction time and low production cost The effect of low, high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

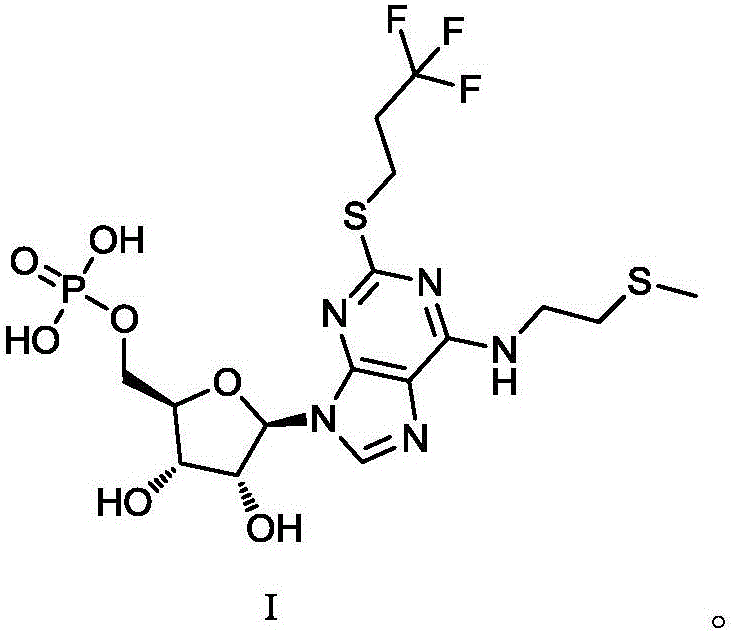

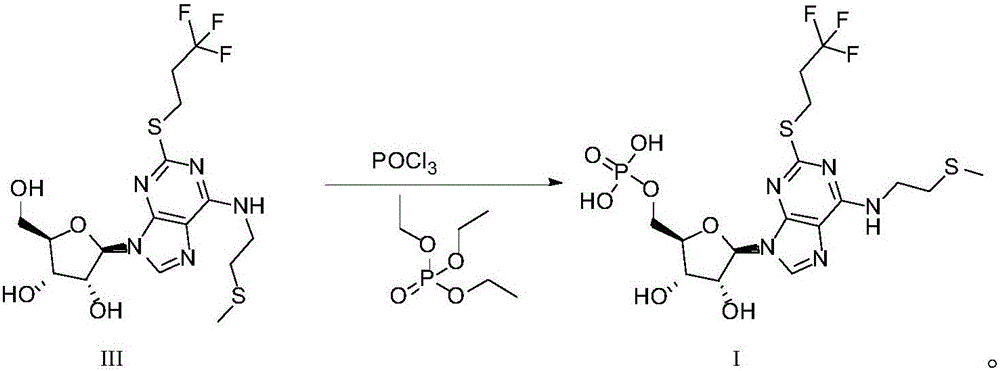

[0046] Embodiment 1: the preparation method of cangrelor intermediate I crude product

[0047]

[0048] 5g of cangrelor intermediate III and 3.42g of 1,8-bisdimethylaminonaphthalene were dissolved in 106g of triethyl phosphate, cooled to 0°C in an ice bath, and 3.27g of phosphorus oxychloride was added dropwise to the reaction solution. The reaction was carried out at 0° C. for 6 hours, and TLC detected that the reaction of the cangrelor intermediate III was complete. A solution of crude cangrelor intermediate I in triethyl phosphate (HPLC purity about 75%) was obtained.

Embodiment 2

[0049] The purification method of embodiment 2 cangrelor intermediate I crude product

[0050] The triethyl phosphate solution of the crude cangrelor intermediate I (HPLC purity about 75%, which can be prepared in Example 1) was poured into 300 mL of ice water containing 13.6 g of sodium bicarbonate, and stirred for 1 hour. The aqueous phase was extracted with diethyl ether (3 x 350 mL) and the organic phase was discarded. The aqueous phase was concentrated under reduced pressure (-0.08MPa~-0.1MPa) at 40°C until no fraction evaporated. 100 ml of ethanol was added to the residue and stirred for 2 hours. The precipitated solid was filtered and washed with 10 mL of ethanol. The obtained solid was redissolved in 80 ml of deionized water, adjusted to pH 2-3 with 1N hydrochloric acid, stirred for 1 hour, filtered, and the obtained solid was washed with 5 ml of deionized water. Dissolve the above solid in 50ml of ethanol, add 5ml of ammonia water with a mass concentration of 25% (...

Embodiment 3

[0051] Embodiment 3: the preparation method of cangrelor intermediate I crude product

[0052] Put 15Kg of cangrelor intermediate III and 10.3Kg of 1,8 bis-dimethylaminonaphthalene into 300Kg of triethyl phosphate, cool the frozen brine to 0-5°C, and drop 9.9Kg of phosphorus oxychloride into the reaction solution. Stir at 0-5°C for 8 hours, TLC detects that the reaction of cangrelor intermediate III is complete. A triethyl phosphate solution of the crude cangrelor intermediate I was obtained, with an HPLC purity of about 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com