Preparation method of chitosan-coated heavy calcium carbonate anti-microbial filler for breathable film

A technology of heavy calcium carbonate and chitosan, which is applied in the fields of composite materials, functional materials, and non-metallic mineral deep processing and utilization, and can solve problems such as low strength of the composite film, failure to meet the use requirements, and the lack of toxicity of grinding aids. , to achieve uniform powder dispersion, prevent bacterial infection, and good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

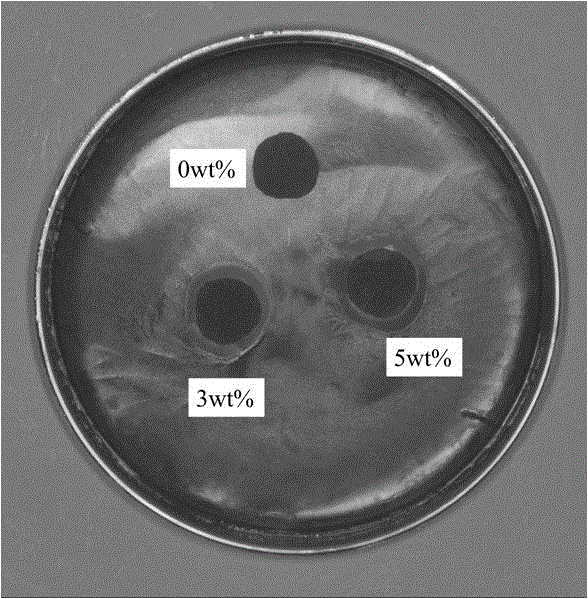

Image

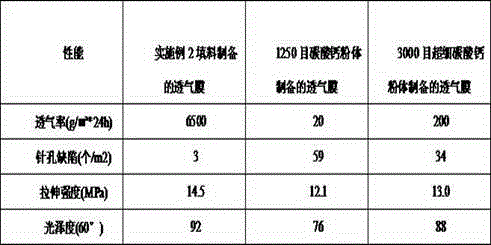

Examples

preparation example Construction

[0032] A preparation method of chitosan-coated ground calcium carbonate antibacterial filler for air-permeable film, comprising the following steps:

[0033] a. The selected marble with calcium carbonate content ≥ 99% is multi-stage crushed to a diameter of 3-10mm. If it is too fine, it will easily introduce other impurities, and if it is too large, it will easily cause low grinding efficiency; then grind it in a dry state to a diameter of 40-10mm. 75μm, get marble powder;

[0034] b. In order to improve the grinding efficiency and drying efficiency, polymer surfactant is added. According to the weight ratio, marble powder: water: polymer surfactant = 1: 0.2 ~ 1.5: 0.001 ~ 0.1 to mix the three; Grind the calcium carbonate powder specially for the membrane to the required index and save the grinding time, and then add any one of alumina ceramic balls, corundum balls or zirconia balls with a diameter of 1-20 mm and accounting for 30-55% of the total weight of the three , stirre...

Embodiment 1

[0050] Select marble ore with calcium carbonate content ≥ 99%, crush it into small pieces with a diameter of 3mm, and put it into the ring rolling mill (the speed of the host machine is 1100r / min, the speed of the fan is 4000r / min) and get D in the dust collector. 50 50μm marble powder;

[0051] Take 4 tons of pure water, add sodium polycarboxylate (commercially available Rohm and Haas 9400) 100kg, mix well in the premix tank, and gradually add 6 tons The obtained marble powder is continuously stirred to make a premixed slurry;

[0052] ③Put 800kg of zirconia balls with a diameter of 1.2mm, 1200kg of zirconia balls with a diameter of 2.2mm, and 2000kg of zirconia balls with a diameter of 3.8mm in the vertical stirring tank, and pump them step by step Prepare the premixed slurry and simultaneously start the agitator from slow to fast, and stir for 1.5h at a stirring speed of 1800r / min;

[0053] ④The stirred mixture is filtered through 100 mesh, and the stirring medium (...

Embodiment 2

[0058] Select marble ore with calcium carbonate content ≥ 99%, crush it into small pieces with a diameter of 8mm, and then put it into a ball mill (the main engine speed is 600r / min, the fan speed is 2000r / min) and get D in the dust collector. 50 40μm marble powder;

[0059] Take 2.5 tons of pure water, add sodium polyacrylate (commercially available molecular weight greater than 10,000) 120kg and mix evenly in the premix tank, gradually add 5.5 tons The obtained powder is continuously stirred to make a premixed slurry;

[0060] ③Put 1200kg of zirconia balls with a diameter of 2mm, 800kg of zirconia balls with a diameter of 4mm, and 700kg of zirconia balls with a diameter of 6mm in the vertical stirring tank, and pump them step by step Prepare the premixed slurry and simultaneously start the agitator from slow to fast, and stir for 2 hours at a stirring speed of 1200r / min;

[0061] ④The mixture after stirring and grinding is filtered through a gap of 80 meshes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com