Thermoplastic elastomer alloy material and preparation method thereof

A thermoplastic elastomer and alloy material technology, which is applied in the field of thermoplastic elastomer alloy materials and their preparation, can solve the problems of temperature resistance of non-environmentally friendly PVC materials, properties of halogen-containing thermoplastic materials, and inability to take both into account, achieving excellent mechanical properties, Low dielectric constant, suitable for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

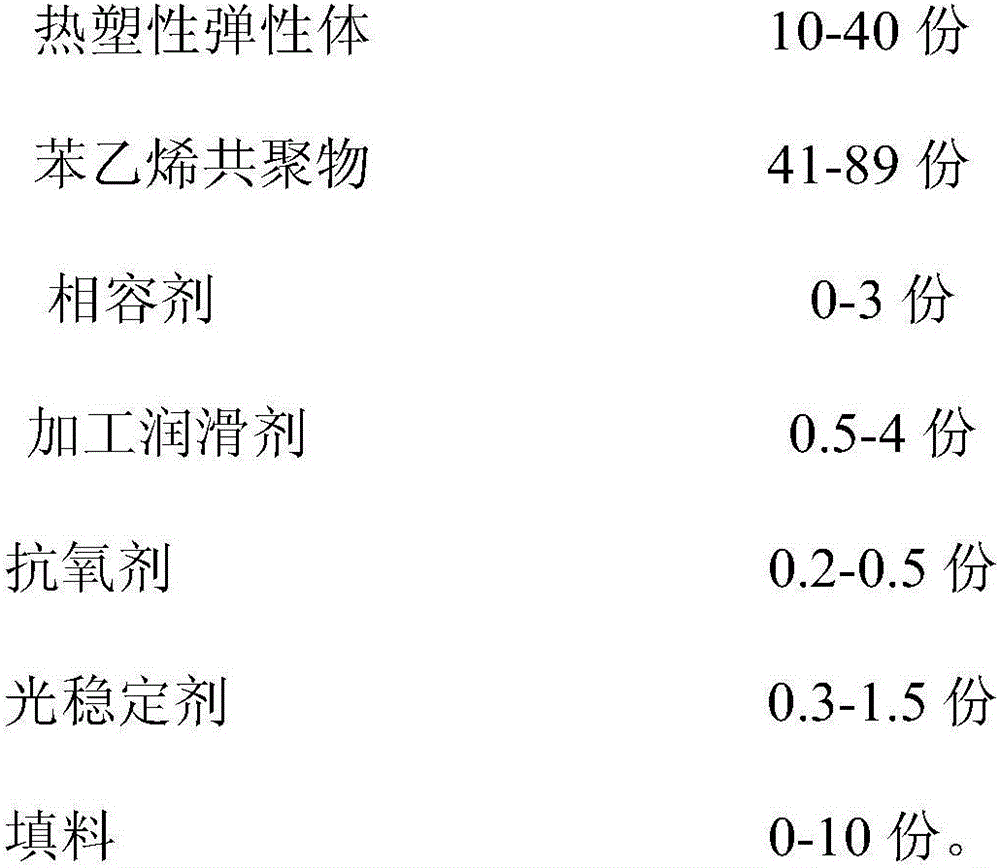

Method used

Image

Examples

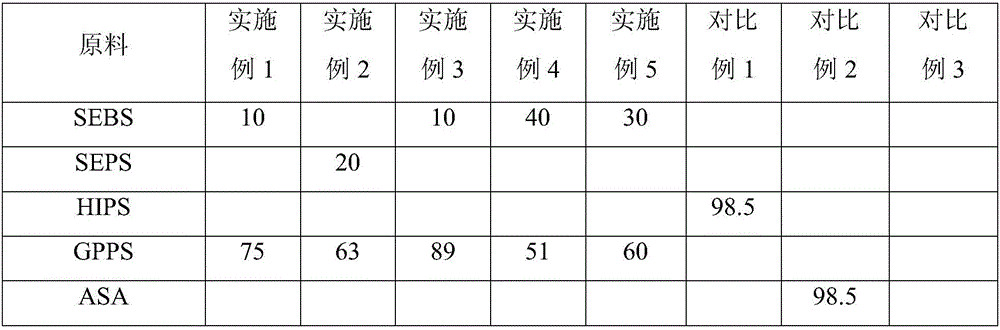

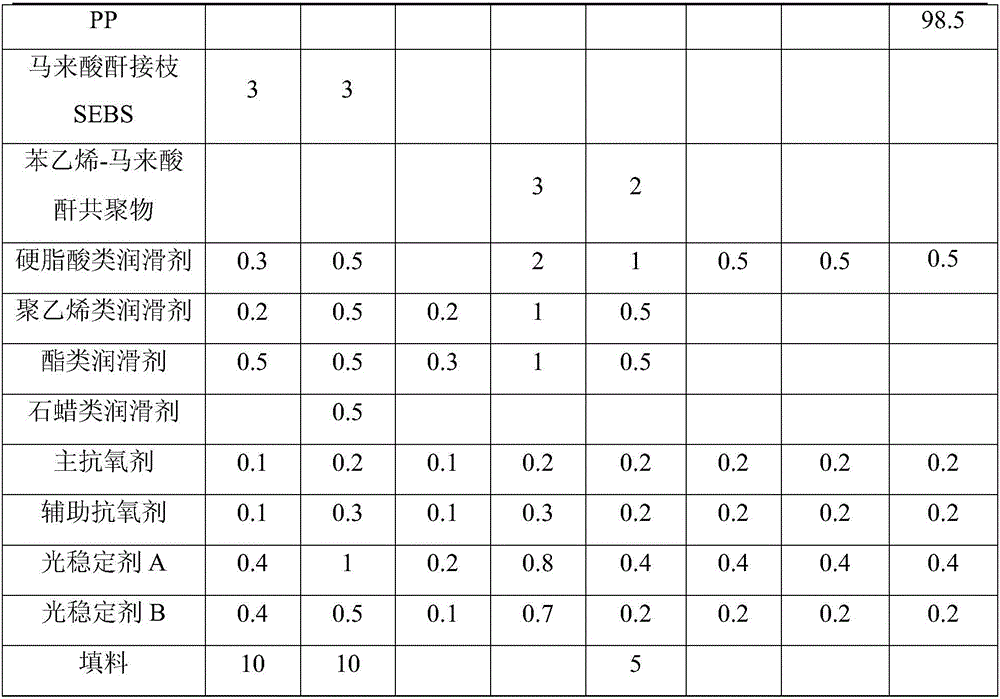

Embodiment 1

[0037] A thermoplastic elastomer alloy material, consisting of the following raw materials in parts by weight: 10 parts of SEBS; 75 parts of GPPS; 3 parts of maleic anhydride grafted SEBS; 0.3 parts of stearic acid lubricant, 0.2 parts of polyethylene lubricant 0.5 part of ester lubricant; 0.1 part of primary antioxidant, 0.1 part of auxiliary antioxidant; 0.4 part of light stabilizer A, 0.4 part of light stabilizer B; 10 parts of calcium carbonate. After weighing each component according to the above-mentioned ratio of parts by mass, add it into a high-mixer for pre-mixing for 10 minutes, plasticize through a twin-screw extruder, extrude and pelletize, and obtain a thermoplastic elastomer alloy material.

Embodiment 2

[0039]A thermoplastic elastomer alloy material, consisting of the following raw materials in parts by weight: 20 parts of SEPS; 63 parts of GPPS; 3 parts of maleic anhydride grafted SEBS; 0.5 parts of stearic acid lubricant, 0.5 parts of polyethylene lubricant 0.5 part of ester lubricant, 0.5 part of paraffin lubricant; 0.2 part of primary antioxidant, 0.3 part of auxiliary antioxidant; 1 part of light stabilizer A, 0.5 part of light stabilizer B; 10 parts of barium sulfate. After weighing each component according to the above-mentioned ratio of parts by mass, add it into a high-mixer for pre-mixing for 10 minutes, plasticize through a twin-screw extruder, extrude and pelletize, and obtain a thermoplastic elastomer alloy material.

Embodiment 3

[0041] A thermoplastic elastomer alloy material, consisting of the following raw materials in parts by weight: 10 parts of SEBS; 89 parts of GPPS; 0.2 parts of polyethylene lubricant, 0.3 part of ester lubricant; 0.1 part of primary antioxidant, auxiliary antioxidant 0.1 part of oxygen agent; 0.2 part of light stabilizer A, 0.1 part of light stabilizer B. After weighing each component according to the above-mentioned ratio of parts by mass, add it into a high-mixer for pre-mixing for 10 minutes, plasticize through a twin-screw extruder, extrude and pelletize, and obtain a thermoplastic elastomer alloy material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com