Degradable plant oil-based lubricating oil and preparation method thereof

A vegetable oil-based, lubricating oil technology, applied in the field of lubricating oil, can solve unavoidable oil pollution, environmental pollution and other problems, achieve the effect of improving anti-wear effect, improving anti-oxidation, high temperature resistance and anti-wear ability, and reducing extrusion strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

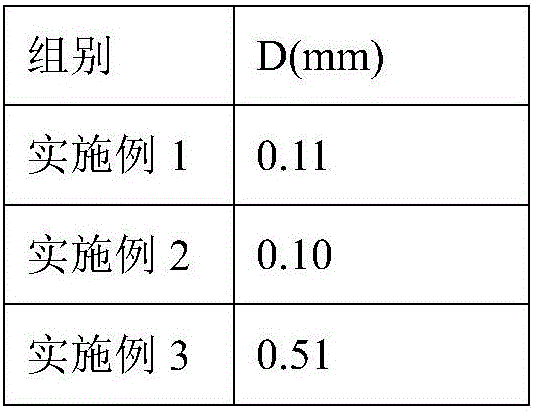

Embodiment 1

[0018] Prepare nano cerium oxide and nano aluminum borate with a mass ratio of 3:2. 3 parts of nano-cerium oxide, 2 parts of nano-aluminum borate, 100 parts of camellia oil, 100 parts of sesame oil, 5 parts of trimethylolpropane, 5 parts of ethanol, 5 parts of ion exchange resin, 20 parts of hydrogen peroxide, 8 parts of lipase Novo435, active 10 parts of silicon powder, 8 parts of TDI, 3 parts of coupling agent KH792, 0.3 parts of fatty alcohol polyoxyethylene ether sodium sulfate (AES), 0.5 parts of polyvinyl n-butyl ether viscosity index modifier.

[0019] Step 1. Mix 100 parts of camellia oil and 100 parts of sesame oil and put them in a shaker to preheat for 2 hours;

[0020] Step 2, weigh 5 parts of trimethylolpropane, add 5 parts of ethanol, and warm to dissolve it;

[0021] Step 3. Then add 5 parts of ion exchange resin into it, and at the same time add 20 parts of hydrogen peroxide dropwise with a separatory funnel, slowly raise the temperature to 100°C, heat up at a...

Embodiment 2

[0030] Example 2 Prepare nano-cerium oxide and nano-aluminum borate with a mass ratio of 2:3. 2 parts of nano cerium oxide, 3 parts of nano aluminum borate. Other raw material consumption, operation steps are the same with embodiment 1.

Embodiment 3

[0031] Example 3 Prepare nano-cerium oxide and nano-aluminum borate with a mass ratio of 1:1. 1 part of nano cerium oxide, 1 part of nano aluminum borate. Other raw material consumption, operation steps are the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com