Leakage hole's leakage rate measuring apparatus

A technology of leak rate measurement and leak hole, which is applied in the field of leak detection, can solve the problems of high development cost, long test cycle, and complex structure of the measurement device, and achieve the effects of wide application range, reduced measurement error, and low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

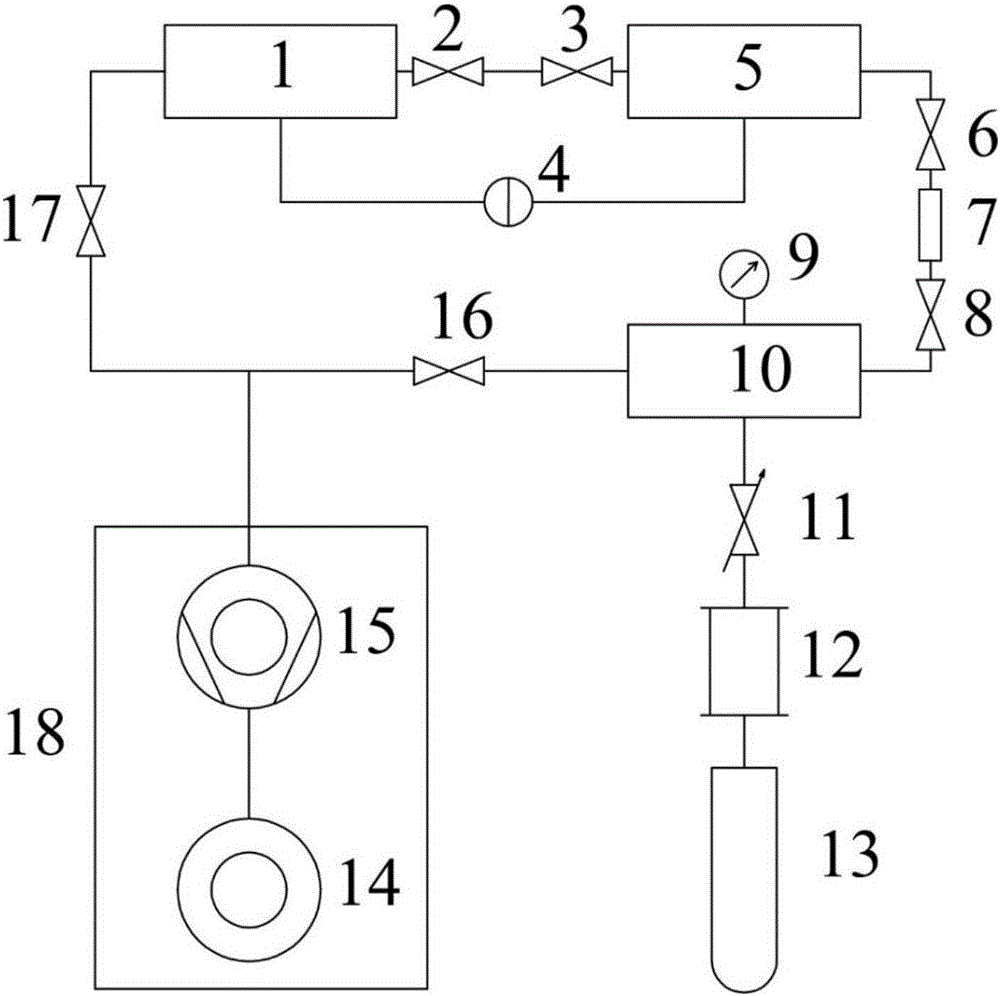

[0029] Such as figure 1 As shown, a leak rate measuring device for a leak includes a reference chamber 1, a first valve 2, a second valve 3, a differential pressure gauge 4, a measuring chamber 5, a fourth valve 6, a measuring unit 7, a fifth valve 8, an absolute Vacuum gauge 9, plenum chamber 10, needle valve 11, flow meter 12, gas cylinder 13, diaphragm pump 14, turbomolecular pump 15, sixth valve 16, third valve 17, air extraction unit 18;

[0030] The gas cylinder 13 is connected to the plenum chamber 10 through a flowmeter 12 and a needle valve 11, and an absolute vacuum gauge 9 is installed on the plenum chamber 10, and the air extraction unit 18 is connected to the plenum chamber 10 through a sixth valve 16, and is connected to the plenum chamber 10 through the sixth valve 16. The third valve 17 is connected with the reference chamber 1, the measurement unit 7 is connected with the measurement chamber 5 through the fourth valve 6, and connected with the pressure-stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com